Sep . 13, 2024 22:57 Back to list

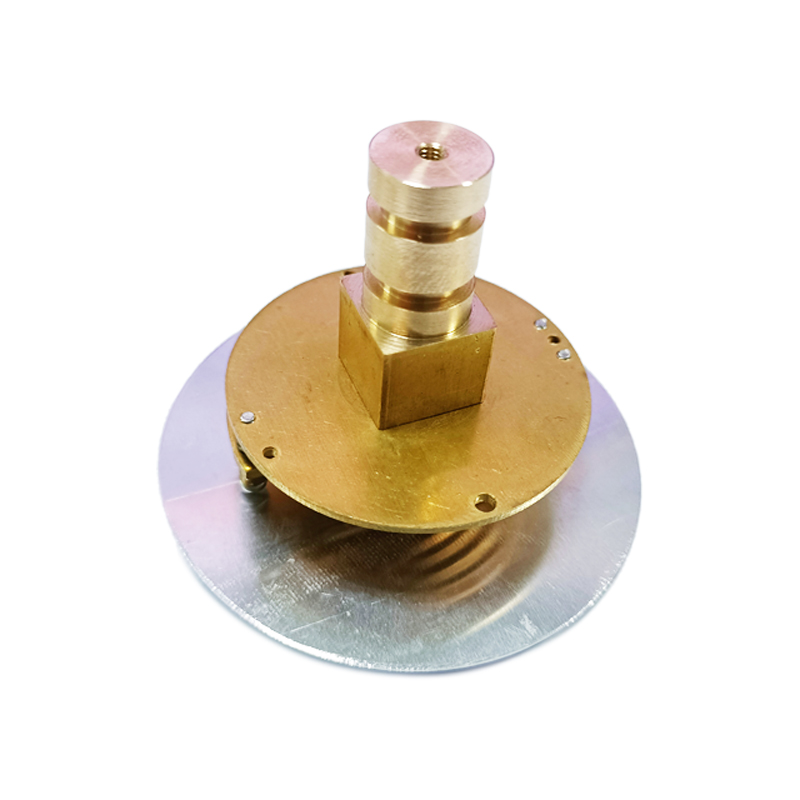

wika sanitary diaphragm pressure gauge

The Importance of Sanitary Diaphragm Pressure Gauges

In the realm of process industries, maintaining precise pressure measurements is critical to ensuring operational efficiency and safety. This is where sanitary diaphragm pressure gauges come into play. These specialized instruments are tailored to meet the unique demands of hygienic environments, making them essential in sectors such as food and beverage, pharmaceuticals, and biotechnology.

What are Sanitary Diaphragm Pressure Gauges?

Sanitary diaphragm pressure gauges are sophisticated devices designed to measure the pressure of fluids in sanitary applications. The essence of these gauges lies in their diaphragm, a flexible membrane that separates the measuring element from the fluid. This design not only protects the gauge from contamination caused by the medium being measured but also ensures that the pressure readings are accurate and reliable.

Typically constructed from high-quality stainless steel, these gauges are built to withstand harsh conditions, including extreme temperatures and corrosive substances. They conform to stringent sanitary standards, making them suitable for compliance with regulations set forth by agencies such as the FDA or EHEDG.

Key Features and Benefits

wika sanitary diaphragm pressure gauge

One of the primary benefits of sanitary diaphragm pressure gauges is their ability to offer a hygienic solution for pressure measurement. The diaphragm design minimizes the risk of stagnation and contamination, thereby maintaining the integrity of the fluid. This is particularly important in industries where hygiene is paramount, such as in dairy processing or pharmaceutical production.

Furthermore, these gauges often come with easy-to-clean surfaces that facilitate maintenance and enhance the durability of the instrument. The ability to effectively clean and sanitize the equipment helps to prevent cross-contamination, which can be detrimental to product quality and safety.

Another significant feature is the versatility of these gauges. They can measure the pressure of not only liquids but also viscous materials and slurries. The diaphragm’s ability to deform allows for accurate readings, regardless of the medium's physical characteristics. Additionally, many models are designed to integrate with digital readouts or remote monitoring systems, providing real-time data for improved process control.

Applications

Sanitary diaphragm pressure gauges find applications in various industries. In the food and beverage sector, they are used to monitor pasteurization processes, measure the pressure in tanks, and ensure the safe transfer of products through pipelines. In pharmaceuticals, these gauges are employed in the manufacturing of sterile products, where maintaining optimal pressure conditions is crucial.

In conclusion, the role of sanitary diaphragm pressure gauges is invaluable in ensuring the reliability and safety of processes in hygienic environments. Their unique design and construction facilitate accurate pressure measurement while adhering to stringent sanitary standards. As industries continue to evolve and prioritize safety and hygiene, these gauges will remain a critical component in achieving operational excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025