Dec . 03, 2024 17:12 Back to list

Suppliers of Differential Pressure Gauges for Various Industrial Applications and Needs

Understanding WIKA Differential Pressure Gauge Suppliers

In industrial applications, precise measurement is paramount. One integral tool in this domain is the differential pressure gauge. These devices are essential for monitoring pressure differences between two points, helping to ensure optimal operation in various systems, including HVAC, filtration, and fluid dynamics. Among the prominent names in this sector is WIKA, a leading supplier of differential pressure gauges known for quality and reliability.

What are Differential Pressure Gauges?

Differential pressure gauges measure the difference in pressure between two inputs, providing critical information that can influence system performance and safety. These gauges are commonly used in processes where pressure differential is an indicator of flow, filter condition, or level measurement. They are particularly vital in applications such as air handling systems where the efficiency of filters must be monitored to prevent system failure.

The Importance of Selecting a Reliable Supplier

Choosing the right supplier for differential pressure gauges is crucial. The supplier should not only provide high-quality products but also offer a range of configurations to meet specific application needs. A reliable supplier should have a solid reputation, as well as a focus on customer service, technical support, and adherence to safety and quality standards.

WIKA A Trusted Name in Measurement Technology

WIKA has established itself as a premier manufacturer and supplier of measurement technology components, including differential pressure gauges. Founded in 1946, the company has consistently focused on innovation and quality. With a presence in over 70 countries, WIKA's commitment to excellence is demonstrated by its expansive product range, which includes mechanical and electronic differential pressure gauges, manometers, and transmitters.

WIKA’s differential pressure gauges are known for their durability and accuracy in varying environmental conditions. The company utilizes high-quality materials and advanced technology to manufacture gauges that can withstand harsh environments, ensuring longevity and reliability in applications where pressure measurements are crucial.

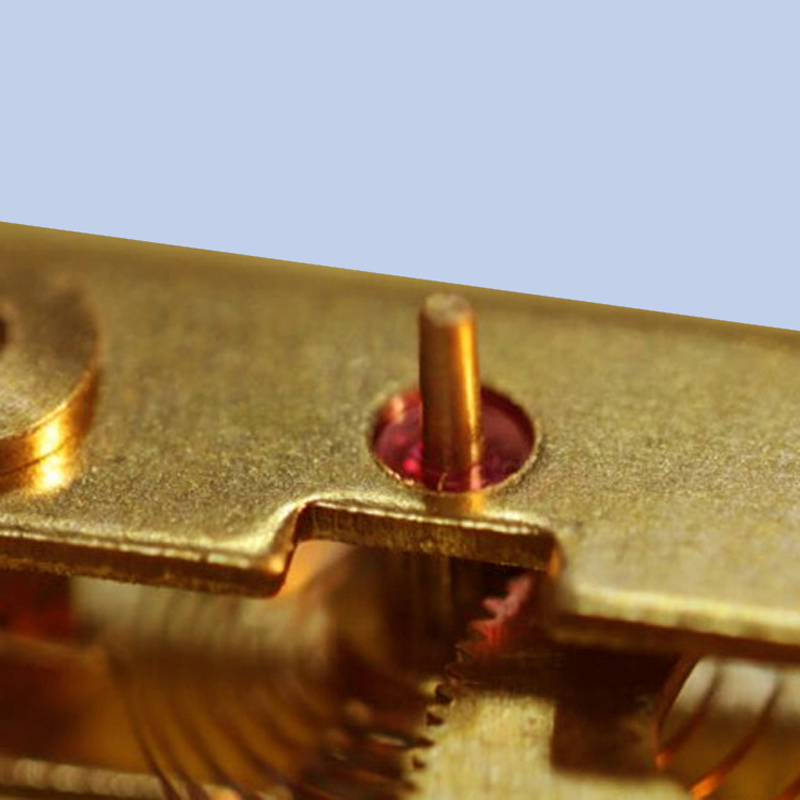

wika differential pressure gauge suppliers

Key Features of WIKA Differential Pressure Gauges

1. Variety of Types WIKA offers various types of differential pressure gauges, including mechanical gauges, which utilize Bourdon tube or diaphragm mechanisms, and electronic gauges, which offer digital readouts and advanced data logging capabilities. This diversity allows businesses to select the right device for their specific needs.

2. High Accuracy and Precision WIKA’s gauges are designed for high accuracy, ensuring that measurements are not only reliable but also repeatable. This feature is essential in critical applications where even minor deviations can lead to significant issues.

3. Innovative Technologies WIKA invests heavily in research and development, continually integrating modern technologies into its products. This includes options like wireless data transmission, allowing for remote monitoring of pressure readings.

4. Customization Options Every application is unique, and WIKA understands this need for customization. They provide various configurations, including different connection sizes, material options, and ranges, which cater to specific application requirements.

5. Technical Support and Service Beyond just selling products, WIKA emphasizes strong customer service and technical support. Their team of experts is available to assist customers in selecting the right gauge and to provide guidance on installation and maintenance.

Conclusion

When it comes to differential pressure gauge suppliers, WIKA stands out for its commitment to quality, innovation, and customer satisfaction. Their product range, which includes various types of differential pressure gauges, is designed to serve a multitude of industrial applications. By choosing a reputable supplier like WIKA, businesses can ensure they are equipped with reliable measurement tools that enhance operational efficiency and safety, ultimately contributing to better overall performance. In an age where precision and reliability are more crucial than ever, partnering with a trusted supplier is a strategic decision that can lead to significant benefits for manufacturers and service providers alike.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025