Nov . 15, 2024 19:09 Back to list

wika differential pressure gauge with diaphragm seal companies

Differential Pressure Gauges with Diaphragm Seals A Comprehensive Overview

Differential pressure gauges are essential instruments in various industries, particularly in process control and monitoring systems. Among the various designs available, the diaphragm seal type is widely favored for its ability to maintain accuracy and reliability in harsh conditions. This article explores the significance, working principles, and applications of these specialized devices, along with a brief overview of leading companies in the field.

At its core, a differential pressure gauge measures the pressure difference between two points within a system. This capability is critical in processes where maintaining specific pressure differentials is necessary for operational safety and efficiency. The diaphragm seal enhances the gauge's performance by providing an isolating barrier between the measuring instrument and the process media. This isolation protects the gauge from corrosive, viscous, or contaminated fluids, which can otherwise hinder measurement accuracy and lead to premature equipment failure.

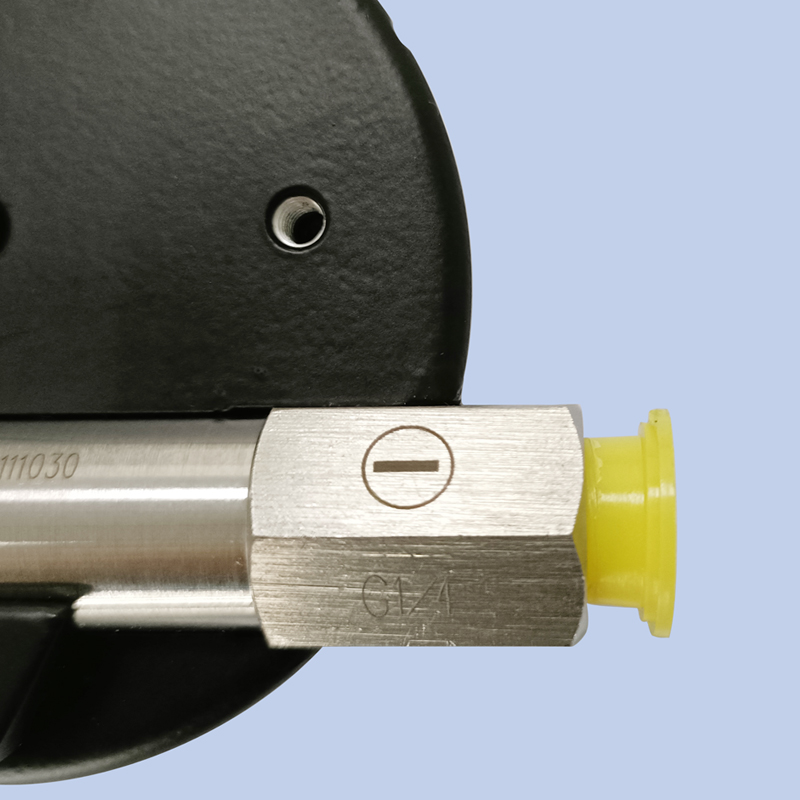

The working principle of a differential pressure gauge with a diaphragm seal involves several components. The diaphragm, typically made of materials like stainless steel or other corrosion-resistant alloys, deflects in response to pressure changes. This deflection is transmitted to a sensing mechanism, often a Bourdon tube or a capacitance-based sensor, which then converts the mechanical movement into a readable pressure value. The design of the diaphragm seal allows for significant flexibility, accommodating pressure fluctuations while ensuring a tight seal to prevent process fluid ingress.

wika differential pressure gauge with diaphragm seal companies

Applications of diaphragm seal differential pressure gauges are numerous and span across various sectors, including petrochemical, pharmaceutical, food and beverage, and water treatment industries. They are commonly used in monitoring filter conditions, measuring liquid levels in tanks, and controlling the pressure in pipelines. The ability to provide accurate readings in hostile environments makes these gauges indispensable for maintaining process integrity and safety.

When it comes to selecting a manufacturer for differential pressure gauges with diaphragm seals, several companies stand out in the industry. These include well-established names such as Ashcroft, WIKA, and Yokogawa. Each of these companies offers a range of innovative solutions, focusing on quality, durability, and accuracy. WIKA, for instance, is renowned for its advanced technology and extensive product offerings, ensuring that customers can find a gauge suited to their specific operational needs.

In conclusion, differential pressure gauges with diaphragm seals are crucial instruments for maintaining process efficiency and safety. Their ability to withstand harsh conditions while delivering accurate measurements makes them a preferred choice across various industries. With reliable manufacturers offering high-quality models, businesses can ensure their processes run smoothly while mitigating risks associated with pressure fluctuations. As industrial demands evolve, so too will the innovations surrounding these essential devices, ensuring their relevance in tomorrow's technological landscape.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025