nov . 26, 2024 17:17 Back to list

Optimal Diaphragm Protection Solutions for Pressure Gauge Performance and Longevity

The Importance of Best Diaphragm Protection in Pressure Gauges

Pressure gauges are essential tools in various industries, serving as indicators of pressure measurements in pipes, tanks, and other pressurized systems. However, ensuring the accuracy and longevity of these instruments is critical, particularly when it comes to diaphragm protection. This article delves into the significance of diaphragm protection in pressure gauges and the best practices to achieve optimal results.

Understanding Diaphragm Protection

A diaphragm pressure gauge features a flexible membrane that separates the measuring element from the process fluid. This membrane, or diaphragm, responds to changes in pressure and translates these changes into a readable format. However, exposure to harsh conditions—such as corrosive fluids, high temperatures, and fluctuating pressures—can adversely affect the diaphragm's integrity, leading to inaccurate readings, potential leaks, and gauge failure.

Diaphragm protection is, therefore, paramount. It not only prolongs the gauge's lifespan but also ensures that the measurements taken are reliable and accurate. Implementing effective diaphragm protection strategies helps mitigate risks associated with process fluid characteristics and operating conditions.

Factors That Affect Diaphragm Performance

1. Process Fluid Characteristics The nature of the fluid—whether it is corrosive, viscous, or contains particulates—plays a significant role in diaphragm durability. Choosing the right diaphragm material, such as stainless steel or fluoropolymer, depending on the fluid composition, is crucial.

2. Operating Temperature High temperatures can lead to thermal expansion, potentially damaging the diaphragm and affecting its responsiveness. Selecting gauges designed for high-temperature applications or incorporating cooling elements can help address this issue.

3. Pressure Fluctuations Continuous or sudden changes in pressure can impose stress on the diaphragm, leading to premature failure. Using dampeners or snubbers can help regulate these fluctuations, enhancing diaphragm protection.

4. Installation Environment Factors such as vibration, shocks, and harsh environmental conditions should be considered when selecting a pressure gauge. Protective enclosures or mounting solutions can help shield the gauge from external forces.

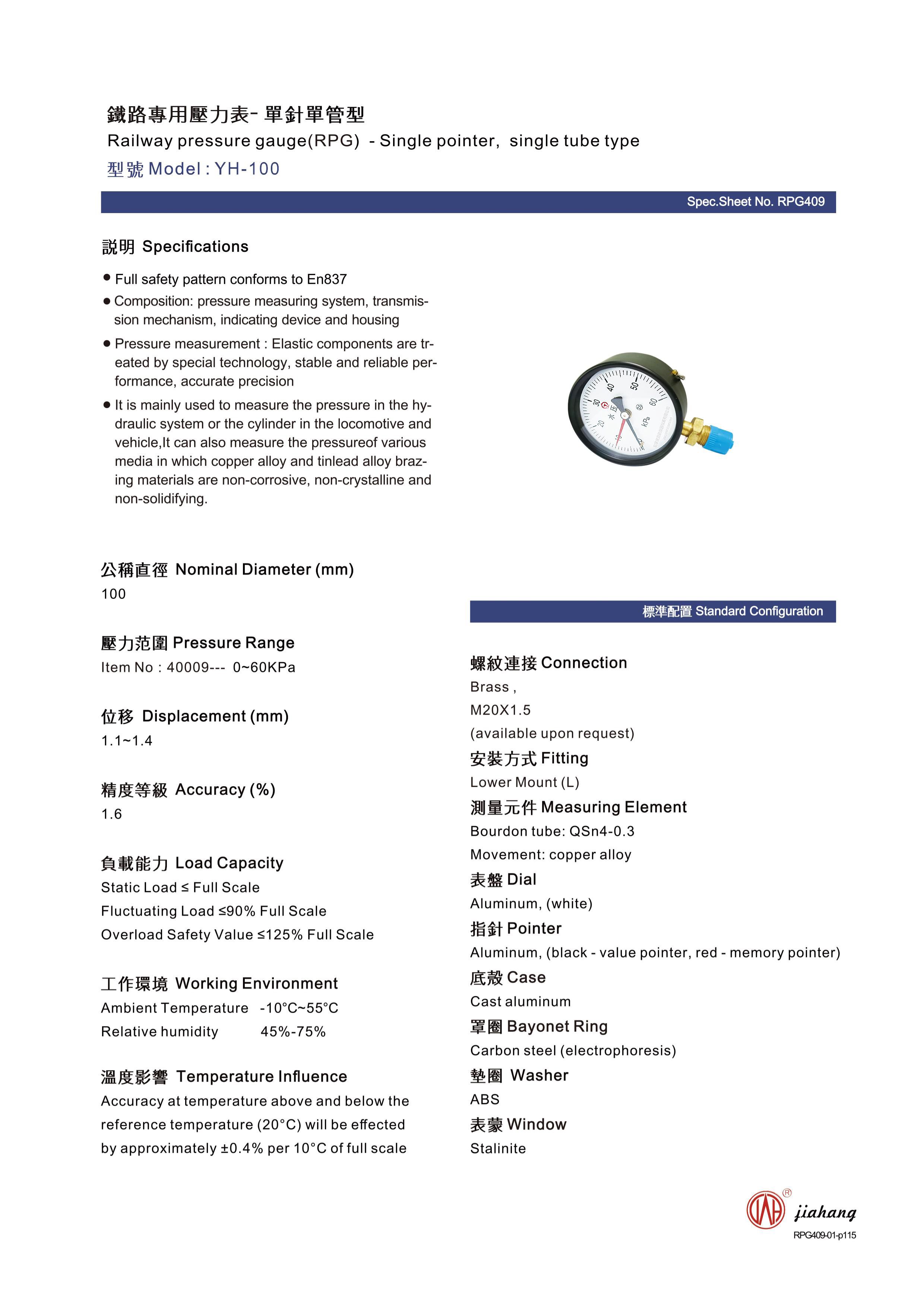

best diaphragm protection pressure gauge

Best Practices for Diaphragm Protection

To ensure optimal diaphragm protection in pressure gauges, several best practices can be adopted

1. Material Selection Choose diaphragm materials compatible with the process fluid. Common materials include bronze, stainless steel, and various elastomers. The selected material should withstand the chemical and physical conditions of the environment.

2. Use of Isolators and Diaphragm Seals Isolation devices can protect the diaphragm from direct exposure to corrosive or particulate-laden fluids. Diaphragm seals create a barrier between the process fluid and the gauge, preventing damage while still allowing for pressure transmission.

3. Proper Calibration and Maintenance Regular calibration and maintenance of pressure gauges are essential to ensure accurate measurements. Establish a routine maintenance schedule to inspect the diaphragm and other components for signs of wear and tear.

4. Limit Pressure Variations Implementing pressure regulation systems can help maintain a stable environment for the diaphragm, reducing the risk of damage due to rapid pressure changes.

5. Environmental Protections When operating in harsh conditions, consider additional protections such as weatherproof casings or insulation to mitigate temperature extremes and environmental stresses.

Conclusion

The diaphragm plays a vital role in the functionality of pressure gauges. Understanding the factors that can impact its performance and implementing best practices for diaphragm protection are essential steps for maintaining the accuracy and reliability of pressure measurement systems. By selecting appropriate materials, employing isolation techniques, and ensuring regular maintenance, industries can enhance the longevity of their pressure gauges while safeguarding against potential failures. Prioritizing diaphragm protection ultimately leads to more reliable operations, enhanced safety, and cost-effective solutions in the long run.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025