nov . 26, 2024 00:42 Back to list

Understanding Pressure Gauges on Fire Extinguishers in China and Their Importance

Understanding the Importance of Pressure Gauges in Chinese Fire Extinguishers

Fire extinguishers are vital devices for combating small fires and are an essential part of fire safety protocols in homes, offices, and industrial settings. In China, as in many parts of the world, fire extinguishers must be regularly inspected and maintained to ensure their functionality during emergencies. A critical component of this maintenance is the pressure gauge. Understanding the role of pressure gauges in fire extinguishers can enhance fire safety awareness and ensure that these important tools are always ready for use.

What is a Pressure Gauge?

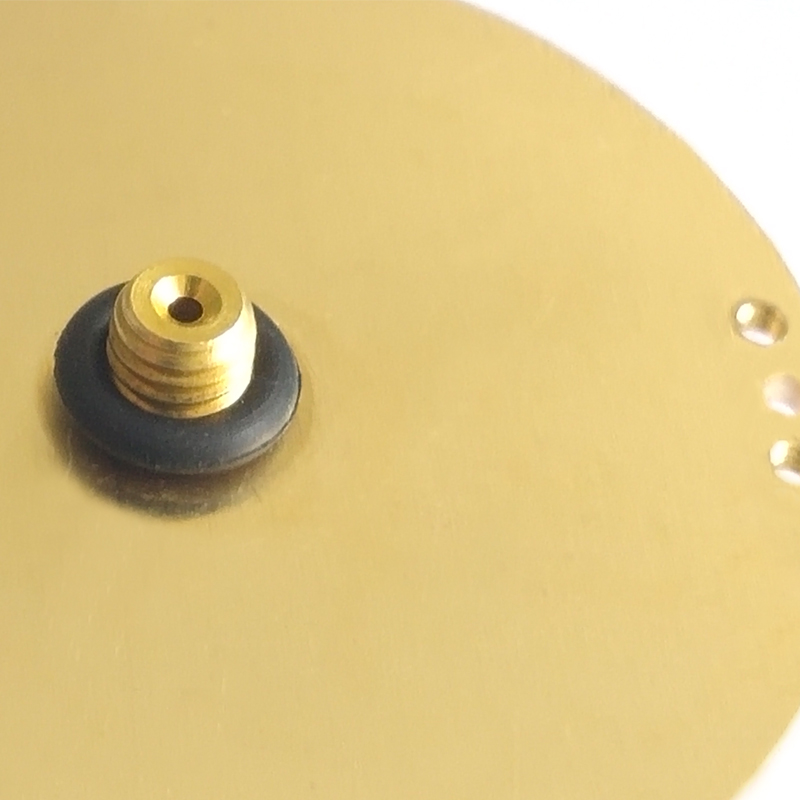

A pressure gauge is a mechanical device that measures the pressure of gases or liquids. In the context of fire extinguishers, the pressure gauge provides a quick visual indication of whether the extinguisher is adequately charged and ready for use. Most fire extinguishers today are equipped with an analogue or digital pressure gauge that displays the pressure within the canister.

Why is Pressure Important?

The effectiveness of a fire extinguisher is directly linked to its internal pressure. Each type of extinguisher is designed to operate at a specific pressure range. If the pressure is too low, the extinguisher may not be able to expel the extinguishing agent effectively. Conversely, if the pressure is too high, it could lead to a rupture of the canister, resulting in hazardous situations. This is why regular monitoring and maintenance of the pressure gauge are critical.

Types of Fire Extinguishers and Their Gauges

In China, common types of fire extinguishers include water-based, foam, dry chemical, and carbon dioxide extinguishers. Each type serves different applications based on the class of fire it is designed to combat. Nonetheless, regardless of the type, all fire extinguishers feature a pressure gauge that indicates whether they are within the operational pressure range.

china fire extinguishers pressure gauge

1. Water-Based Extinguishers Generally used for Class A fires (ordinary combustibles), these extinguishers usually have a pressure gauge that indicates acceptable pressure levels. If the needle points to the green zone, the extinguisher is ready for use.

2. Dry Chemical Extinguishers Frequently employed for Class B (flammable liquids) and Class C (electrical) fires, these extinguishers also have a pressure gauge. A reading in the green zone assures users that the extinguisher is fully charged.

3. Carbon Dioxide Extinguishers Used primarily for electrical fires, these do not have a gauge in all models; instead, users may need to check the weight as a means of ensuring functionality.

Conducting Regular Inspections

To ensure the reliability of fire extinguishers, regular inspections should be performed. In China, it is common practice to check fire extinguishers every month. During these checks, look for the following

1. Gauge Reading Ensure the indicator is in the green zone. 2. Physical Condition Inspect the exterior for dents, corrosion, or damage. 3. Accessibility Ensure extinguishers are easy to access and not obstructed. 4. Maintenance Tags Check for the last service date to ensure compliance with regulation guidelines.

Conclusion

In conclusion, pressure gauges play an instrumental role in the functionality of fire extinguishers in China. They provide essential information about the readiness of the extinguisher to perform its life-saving function. By understanding how pressure gauges work and maintaining regular inspections, individuals and organizations can enhance fire safety preparedness and ensure that their fire extinguishers remain effective in times of need. As fire safety regulations continue to evolve, awareness and education about these crucial devices will remain paramount in safeguarding lives and property.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025