jan . 20, 2025 14:41 Back to list

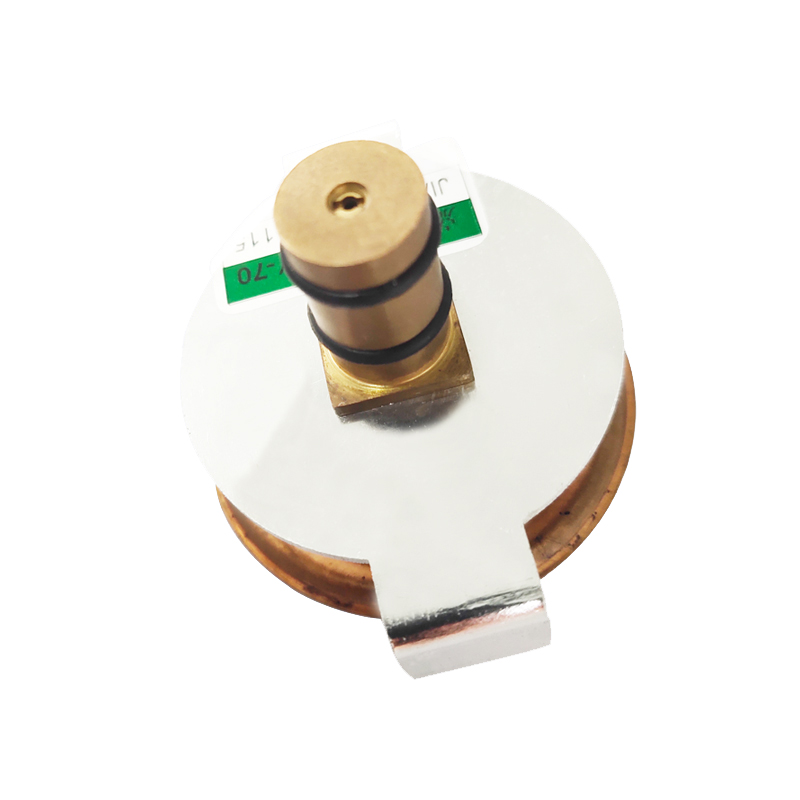

Differential pressure gauge with magnetic piston-YCC80

Differential pressure gauges play a pivotal role in myriad industrial applications, offering precision and reliability in measuring pressure differentials. Unlike traditional pressure gauges, these instruments provide crucial data for maintaining efficiency and safety in environments ranging from oil refineries to pharmaceutical production lines. Here, we delve into the profound aspects of these gauges, emphasizing their real-world efficacy and showcasing why they are indispensable in modern industrial setups.

In terms of authoritativeness, regulatory bodies such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) set the benchmarks for pressure gauge performance. Compliance with these standards not only ensures user safety but also enhances the credibility of the equipment in professional settings. Manufacturers that align their products with these standards are often preferred by industries looking for quality assurance and adherence to global best practices. From a trustworthiness perspective, utilizing cutting-edge technology in differential pressure gauges assures users of their accuracy and reliability. Modern gauges incorporate digital interfaces and connectivity features that allow real-time monitoring and integration with industrial IoT systems. This technology simplifies data analysis and aids in predictive maintenance strategies, thereby reducing unexpected downtimes. Furthermore, the self-diagnostic features present in many advanced models enhance trust in their uninterrupted functionality over prolonged periods. An understanding of various applications underscores the necessity of differential pressure gauges across different sectors. In the oil and gas industry, for instance, they monitor pressure differentials in pipelines, preventing leaks and ensuring safe operation. Similarly, in the pharmaceutical sector, they ensure the integrity of cleanrooms and containment systems, safeguarding product quality and compliance with stringent health regulations. In conclusion, the expertise and real-world application of differential pressure gauges demonstrate their critical role in contemporary industrial environments. Selecting the right gauge backed by authoritative standards and trusted brands enhances both operational efficiency and safety. Their technological advancements underscore a forward-thinking approach, ensuring that differential pressure gauges remain a cornerstone in industrial instrumentation.

In terms of authoritativeness, regulatory bodies such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) set the benchmarks for pressure gauge performance. Compliance with these standards not only ensures user safety but also enhances the credibility of the equipment in professional settings. Manufacturers that align their products with these standards are often preferred by industries looking for quality assurance and adherence to global best practices. From a trustworthiness perspective, utilizing cutting-edge technology in differential pressure gauges assures users of their accuracy and reliability. Modern gauges incorporate digital interfaces and connectivity features that allow real-time monitoring and integration with industrial IoT systems. This technology simplifies data analysis and aids in predictive maintenance strategies, thereby reducing unexpected downtimes. Furthermore, the self-diagnostic features present in many advanced models enhance trust in their uninterrupted functionality over prolonged periods. An understanding of various applications underscores the necessity of differential pressure gauges across different sectors. In the oil and gas industry, for instance, they monitor pressure differentials in pipelines, preventing leaks and ensuring safe operation. Similarly, in the pharmaceutical sector, they ensure the integrity of cleanrooms and containment systems, safeguarding product quality and compliance with stringent health regulations. In conclusion, the expertise and real-world application of differential pressure gauges demonstrate their critical role in contemporary industrial environments. Selecting the right gauge backed by authoritative standards and trusted brands enhances both operational efficiency and safety. Their technological advancements underscore a forward-thinking approach, ensuring that differential pressure gauges remain a cornerstone in industrial instrumentation.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025