aug . 08, 2024 07:15 Back to list

Exploring Quotes and Insights on Diaphragm Pressure Gauges and Their Applications in Industry

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

Diaphragm pressure gauges are essential instruments employed across various industries for measuring pressure in fluids and gases. Their design and functionality make them particularly advantageous in applications involving corrosive, viscous, or high-temperature substances. This article delves into the intricacies of diaphragm pressure gauges, their advantages, applications, and best practices for selection and maintenance.

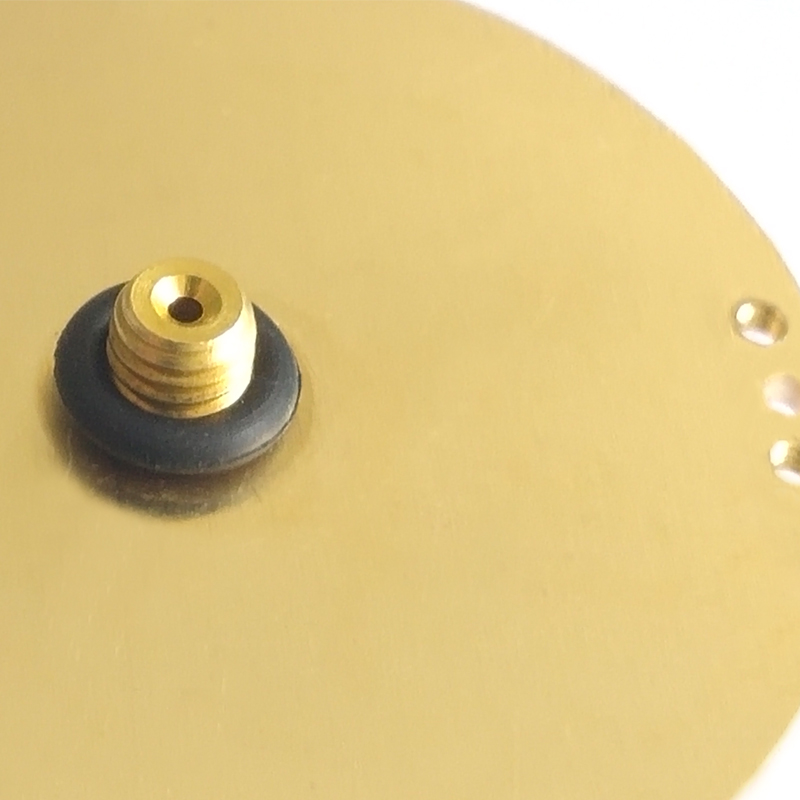

At the core of a diaphragm pressure gauge is a flexible membrane, commonly made from materials such as stainless steel, bronze, or special elastomers. When pressure is applied, the diaphragm deflects, translating the pressure exerted into a mechanical movement. This movement is then transmitted to a needle on a dial or through an electronic signal in digital models, providing a readout of the pressure level. The simplicity of this mechanism is key to the reliability and accuracy of these gauges, making them a preferred choice for many industrial applications.

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

Moreover, diaphragm gauges are available in various configurations to cater to specific needs. For example, gauges can be designed with a solid front or blow-out back, depending on the requirements for safety and performance. In high-pressure applications, the selection of materials for the diaphragm becomes critical. Gauges made with high tensile strength materials can endure greater stress, ensuring longevity and reliability in pressure measurement.

diaphragm pressure gauges quotes

When it comes to applications, diaphragm pressure gauges are ubiquitous. They find use in industries ranging from oil and gas, chemical processing, to food and beverage manufacturing. For instance, in the chemical industry, precise pressure readings are crucial for controlling reactions and ensuring safety. Similarly, in the food industry, maintaining appropriate pressure levels in processes like pasteurization or packaging can guarantee product quality and safety.

Despite their robustness, choosing the right diaphragm pressure gauge requires careful consideration. Users must assess factors such as pressure range, compatibility with the media being measured, and the operating environment. For example, a high-pressure application may require a gauge with higher durability, while a corrosive media may necessitate the use of specialized materials to prevent degradation.

Maintenance of diaphragm pressure gauges is equally important to ensure their accuracy and longevity. Routine checks for leaks, calibration, and visual inspections for wear and tear should be standard practice. If a gauge is displaying erratic or fluctuating readings, it may need recalibration or replacement of the diaphragm. Establishing a maintenance schedule can help in identifying potential issues before they lead to critical failures.

In conclusion, diaphragm pressure gauges play a pivotal role across various sectors by providing reliable and accurate pressure measurements. Their adaptability to different environments and processes makes them indispensable tools in industrial applications. By understanding their design, functions, and proper maintenance procedures, users can extend the lifespan of these gauges and ensure their systems run smoothly and efficiently. Investing in quality diaphragm pressure gauges not only enhances operational safety but also contributes significantly to overall process efficiency.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025