nov . 27, 2024 14:56 Back to list

Top Precision Instruments for Accurate Pressure Measurement and Monitoring Solutions

Precision Instruments The Importance of Pressure Gauges

In various industries and scientific research, precision instruments play a vital role in ensuring safety, reliability, and efficiency. Among these instruments, pressure gauges stand out as essential tools for measuring the pressure of gases and liquids. Whether in manufacturing, HVAC systems, laboratory settings, or oil and gas extraction, these devices provide critical data that informs operational decisions and helps maintain equipment integrity.

What is a Pressure Gauge?

A pressure gauge is an instrument used to measure the pressure of fluids—whether they are gases or liquids. It typically consists of a sensing element, a mechanism to convert this pressure into a readable format, and a display. There are various types of pressure gauges, including analog gauges with mechanical dials and digital gauges that provide electronic readouts. Each type has its own advantages and suitability depending on the application.

Types of Pressure Gauges

1. Bourdon Tube Gauges One of the most common types, Bourdon tube gauges use a curved tube that straightens under pressure. The movement of the tube is converted into a rotational movement that displays the pressure on a needle and dial. They are durable and widely used in various industries.

2. Diaphragm Gauges These gauges use a flexible diaphragm that moves in response to pressure changes. They are particularly useful for measuring low pressures and are often used in applications involving corrosive or viscous fluids.

3. Digital Pressure Gauges With advancements in technology, digital gauges have become more prevalent. They provide accurate readings and can often display measurements in multiple units. Additionally, many digital gauges incorporate features like data logging and remote monitoring.

4. Manometers Although often categorized differently, manometers are pressure measuring devices that use liquid columns to measure pressure differences. They are particularly useful in laboratory settings for precise measurements.

Importance of Accuracy

The accuracy of pressure gauges is paramount. In industrial applications, even small deviations in pressure can lead to catastrophic failures, equipment damage, or safety hazards. For example, in petroleum extraction, accurate pressure measurements can determine the efficiency of pumping systems and assist in the safe handling of high-pressure fluids. Similarly, in HVAC systems, maintaining the correct pressure ensures optimal system performance and energy efficiency.

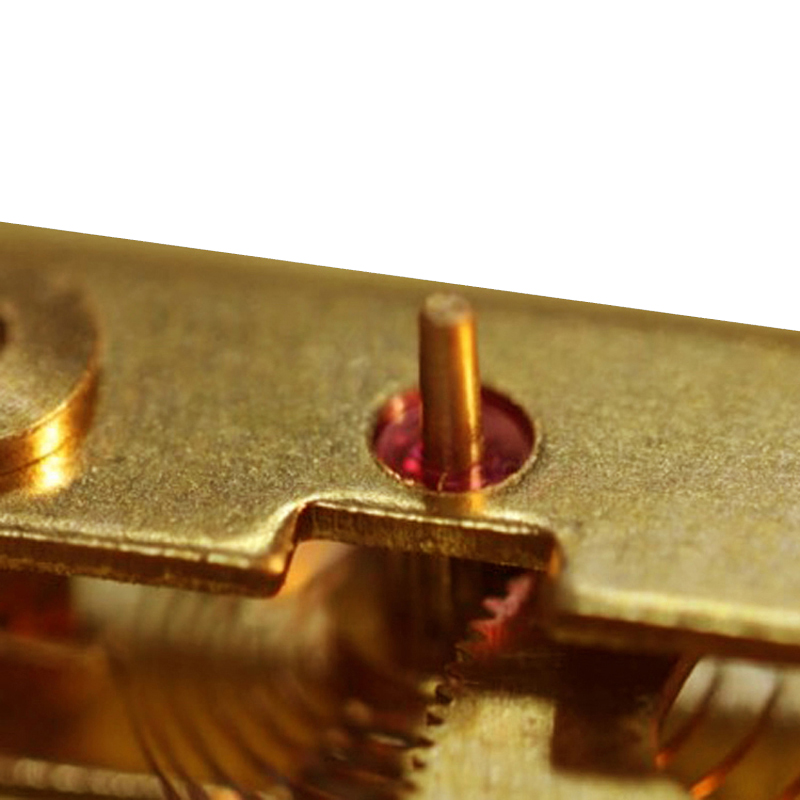

famous precision instruments pressure gauge

Calibration and Maintenance

To ensure accurate readings, regular calibration of pressure gauges is essential. Calibration involves comparing the gauge's readings against a known standard and making adjustments as necessary. This process can be complex and typically requires specific equipment and expertise. In addition to calibration, routine maintenance is crucial. This includes checking for leaks, ensuring the integrity of seals, and inspecting the mechanical components for wear and tear. Neglecting maintenance can result in inaccurate readings, ultimately leading to system failures or safety incidents.

Applications of Pressure Gauges

Pressure gauges are employed across a myriad of industries

- Manufacturing Used to monitor and control pressure in processes such as pneumatic conveying, hydraulic systems, and chemical mixing.

- Automotive Essential in assessing tire pressure and ensuring safe vehicle operation.

- Aerospace Critical for monitoring cabin pressure and fuel systems, where inaccuracies can have severe implications.

- Medical Used in various healthcare devices, including ventilators and anesthesia machines, where precise pressure measurements can be a matter of life and death.

Conclusion

In conclusion, pressure gauges are indispensable precision instruments that provide essential data for various applications across multiple industries. Their accuracy and reliability are crucial for maintaining safe operations and enhancing efficiency. As technology advances, the development of pressure gauges continues to evolve, offering advanced features for monitoring and data analysis. Regular calibration and maintenance remain vital for ensuring their longevity and accuracy. Understanding the significance of these instruments can help industries maximize productivity while ensuring safety and compliance with regulatory standards. Thus, investing in quality pressure gauges and upholding proper maintenance practices is a decision that cannot be overlooked.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025