jul . 28, 2024 12:36 Back to list

High-Performance Flush Diaphragm Pressure Gauges for Accurate Industrial Measurements and Applications

The Importance of Flush Diaphragm Pressure Gauges in Industrial Applications

In the realm of industrial instrumentation, ensuring accurate pressure measurement is crucial for the seamless operation of various processes. Among the tools available for this purpose, flush diaphragm pressure gauges stand out for their reliability and versatility, particularly in challenging environments. These gauges are specifically designed to measure pressure in situations where contaminated or viscous fluids are present, providing a solution to common measurement challenges.

What is a Flush Diaphragm Pressure Gauge?

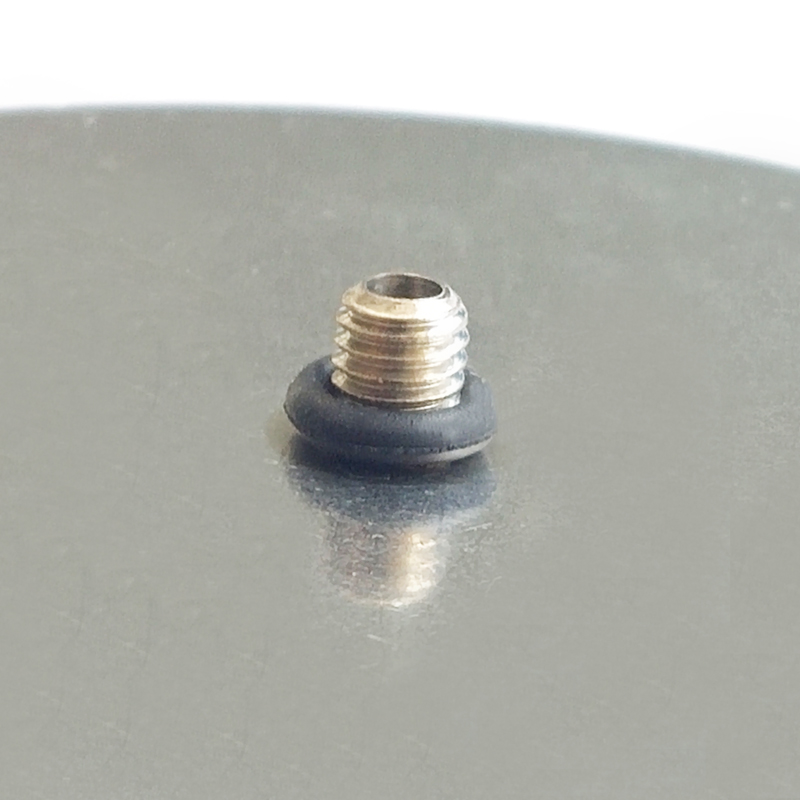

A flush diaphragm pressure gauge features a flexible diaphragm that separates the measuring element from the process fluid. Unlike traditional pressure gauges, which may have protruding elements suited for clean fluids, a flush diaphragm design allows for direct contact with the fluid and eliminates the risks of clogging. This design is especially beneficial for viscous, sediment-laden, or corrosive media, where standard gauges would falter due to blockage or damage.

Key Benefits

1. Prevention of Clogging One of the most significant advantages of flush diaphragm pressure gauges is their ability to prevent clogging. The flat surface of the diaphragm enables easy cleaning and reduces the chances of debris accumulation, which can compromise the accuracy of pressure readings.

2. Versatility Across Applications These gauges are ideal for various industries, including food and beverage, pharmaceuticals, oil and gas, and chemical processing. Their rugged design means they can operate effectively in environments where other gauges would fail.

3. Hygienic Design In sectors like food processing and pharmaceuticals, hygiene is paramount. Flush diaphragm gauges are designed to meet strict sanitary standards, ensuring no contamination occurs during measurement processes. This is achieved through materials that are resistant to corrosion and can withstand frequent cleaning.

flush diaphragm pressure gauge factory

4. Accurate and Reliable Measurements Flush diaphragm pressure gauges maintain high levels of accuracy despite operating in harsh conditions. The absence of pressure “dead legs” – areas where fluid could stagnate – ensures that measurements reflect true process conditions, contributing to optimal operational performance.

Manufacturing Considerations

When selecting a manufacturer for flush diaphragm pressure gauges, several factors should be taken into account. A reputable factory should be committed to quality control and utilize advanced manufacturing techniques to ensure the durability and accuracy of their products. Ideally, manufacturers will also offer customization options to cater to specific application requirements, such as materials, range, and connection sizes.

Moreover, certifications, such as ISO 9001, can be indicative of a factory's commitment to quality management systems. It is also beneficial to choose a manufacturer that provides comprehensive technical support and after-sales service, ensuring that any issues can be resolved swiftly, thus minimizing downtime.

Conclusion

Flush diaphragm pressure gauges are an indispensable tool in the arsenal of pressure measurement devices, particularly for industrial applications where traditional gauges may not perform adequately. Their ability to handle challenging media without clogging, along with their hygienic design and reliable accuracy, makes them essential in sectors that prioritize high standards of quality and safety. As industries continue to evolve and face new challenges, investing in reliable pressure measurement technology like flush diaphragm pressure gauges will remain vital for maintaining efficient operations and ensuring process integrity.

In choosing the right manufacturer, companies can ensure they receive a product that not only meets but exceeds their operational requirements, ultimately contributing to greater productivity and safety in their processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025