okt . 12, 2024 05:52 Back to list

high quality differential pressure gauge 1 4 fnpt

Understanding High-Quality Differential Pressure Gauges Focus on 1-4 FNPT Models

In industrial applications, the ability to measure pressure accurately is crucial for ensuring operational efficiency and safety. Among various instruments used for this purpose, high-quality differential pressure gauges stand out, particularly the 1-4 FNPT (Female National Pipe Thread) models. These devices are essential for measuring the difference in pressure between two points, allowing for better monitoring and control of fluid systems.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument designed to measure the difference in pressure between two points in a system. This type of gauge is particularly useful in applications such as HVAC systems, fluid management, water treatment processes, and many industrial configurations. The readings provided by differential pressure gauges can indicate flow rates, filter conditions, and liquid levels, among other critical parameters.

The Importance of High Quality

When selecting a differential pressure gauge, quality is of utmost importance. High-quality gauges offer several advantages, such as increased accuracy, durability, and reliability. These attributes are particularly vital in high-pressure environments or where the slightest fluctuation can affect the overall system performance. Poor quality gauges may produce erroneous readings, leading to costly downtime or unsafe operating conditions.

High-quality differential pressure gauges are usually made with robust materials designed to withstand various environmental factors such as temperature fluctuations, moisture, and corrosive substances

. The precision engineering involved in the manufacturing of these gauges ensures they can effectively measure small pressure differences with great accuracy.Focus on 1-4 FNPT Design

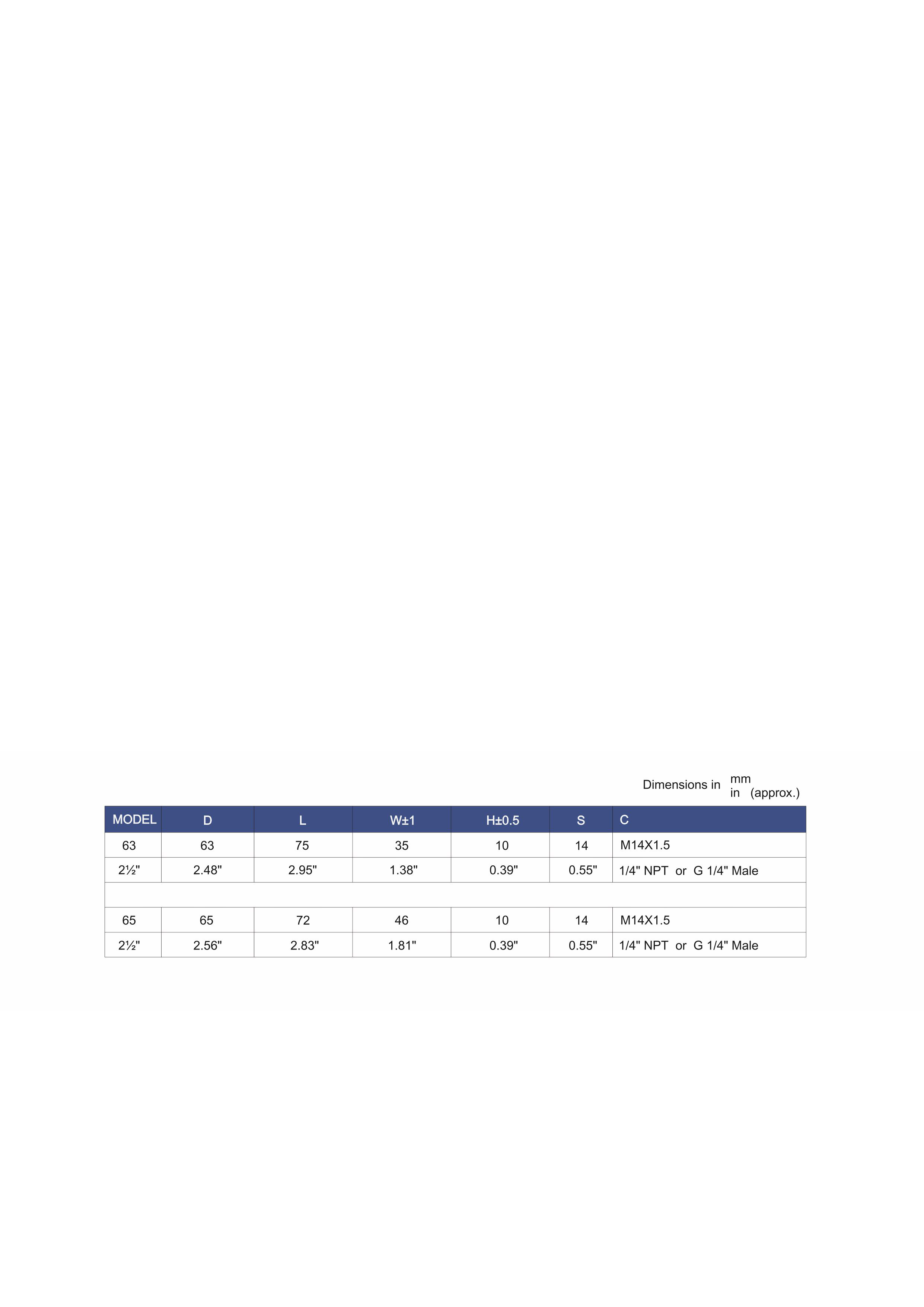

The designation “1-4 FNPT” refers to the size and threading standards of the gauge. The FNPT (Female National Pipe Thread) designation indicates that the gauge will fit securely into systems that utilize female national pipe thread fittings. These fittings are commonly used in plumbing and piping systems owing to their versatility and widespread acceptance in different industries.

high quality differential pressure gauge 1 4 fnpt

A 1-4 FNPT differential pressure gauge typically offers a nominal diameter of 1 inch and can operate under varying pressure ranges. This particular size ensures compactness while allowing for efficient pressure measurement in limited spaces. Furthermore, the FNPT design enhances the seal and reduces the potential for leaks, making it a reliable choice for critical applications.

Applications of Differential Pressure Gauges

Differential pressure gauges are extensively used across various sectors including

1. HVAC Systems To monitor air or fluid flow through filters, allowing maintenance to be performed before excessive pressure drops occur.

2. Water Treatment To measure the pressure difference across filtration systems, ensuring filters remain effective and functional.

3. Process Industries Used in chemical processing, pharmaceuticals, and oil and gas sectors to monitor the flow of materials through various stages of production.

4. Utility Monitoring To manage utilities more effectively by tracking pressure conditions that affect overall system performance.

Conclusion

High-quality differential pressure gauges, particularly the 1-4 FNPT models, play a crucial role in maintaining the efficacy and safety of fluid systems across various industries. Their precision, durability, and ease of integration into existing systems underscore their utility in achieving operational goals. By investing in reliable differential pressure gauges, businesses can minimize operational risks, enhance productivity, and ensure compliance with safety regulations. Understanding the importance of quality in pressure measurement can lead to better decision-making, ultimately contributing to overall system performance and reliability.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025