sep . 28, 2024 19:03 Back to list

Top Quality Precision Pressure Gauges Available in India for Accurate Measurements

High-Quality Precision Pressure Gauges in India

In today’s industrial landscape, the demand for high-quality precision pressure gauges is on the rise. These gauges are crucial instruments used across various sectors, including manufacturing, oil and gas, pharmaceuticals, and food processing. The importance of accurate pressure measurement cannot be overstated, as it ensures operational efficiency, safety, and compliance with industry standards.

Understanding Pressure Gauges

A pressure gauge is a device used to measure the pressure of liquids or gases. Pressure is a critical parameter in many industrial processes, and inaccuracies can lead to inefficiencies, equipment failure, or even catastrophic incidents. High-quality precision pressure gauges offer improved accuracy, reliability, and durability compared to standard gauges, making them essential for industries that rely on precise measurements.

Types of Precision Pressure Gauges

Pressure gauges come in various types, each designed for specific applications. The most common types include

1. Bourdon Tube Gauges These are the most widely used pressure gauges. They consist of a coiled tube that straightens when pressure is applied, moving a needle to indicate the pressure reading. They are robust and suitable for a wide range of applications.

2. Diaphragm Gauges These are used for measuring low pressures and are ideal for corrosive environments. The diaphragm flexes under pressure, and this movement is translated into a pressure reading.

3. Digital Pressure Gauges These offer enhanced accuracy and ease of reading. They feature electronic sensors that provide real-time data and can integrate with digital systems for better monitoring.

The Indian Market for Pressure Gauges

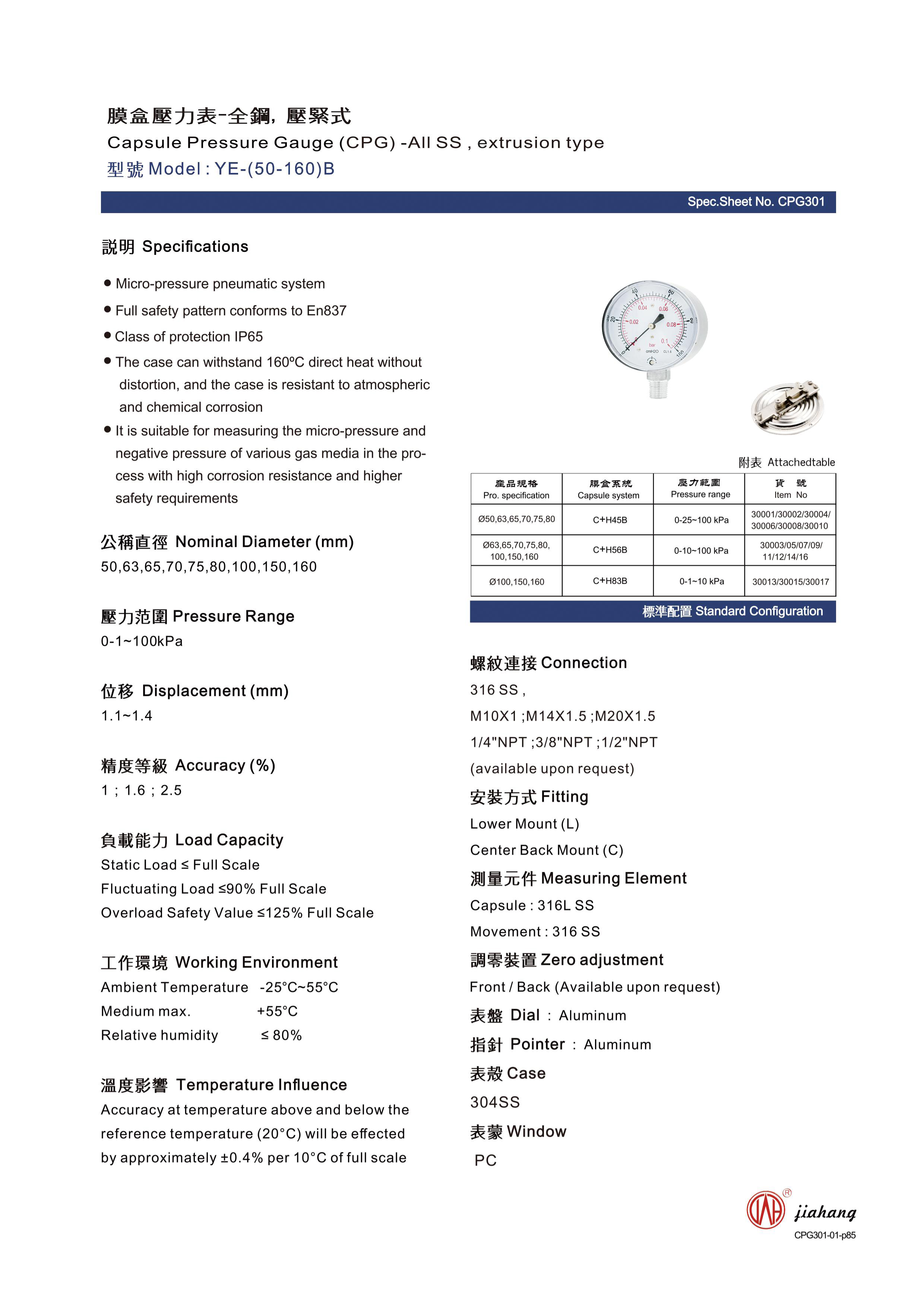

high quality precision pressure gauge india

India's industrial growth has led to an increased demand for precision pressure gauges. Various manufacturers specialize in producing high-quality gauges that meet international standards. These companies invest in advanced technology and quality control processes to ensure their products offer accurate measurements even in the most challenging environments.

One notable aspect of the Indian market is the emphasis on localization. Many companies are focusing on manufacturing pressure gauges locally to reduce costs and improve supply chain efficiency. This has also encouraged innovation, with Indian manufacturers developing unique pressure gauge solutions tailored to local industries.

Quality Standards and Testing

To ensure the reliability and accuracy of pressure gauges, manufacturers in India adhere to strict quality standards. Organizations such as the Bureau of Indian Standards (BIS) set guidelines for manufacturing and testing pressure gauges. These gauges undergo rigorous testing procedures, including calibration, pressure testing, and environmental testing to ensure they can withstand extreme conditions.

Adopting international standards, such as ISO 9001, is also common among leading manufacturers. This commitment to quality not only enhances the reputation of Indian products but also opens export opportunities.

Applications of Precision Pressure Gauges

Precision pressure gauges are used in a multitude of applications. In the oil and gas industry, they are essential for monitoring pressure in pipelines and ensuring the safe extraction of resources. In manufacturing, they help maintain the optimal pressure in machinery, preventing breakdowns and improving efficiency.

In the pharmaceutical industry, where precision is paramount, these gauges ensure that processes remain within safe operating ranges, which is crucial for product quality and compliance with health regulations. Furthermore, in the food processing sector, they help monitor pressure in processes like canning and bottling, ensuring safety and consistency.

Conclusion

The demand for high-quality precision pressure gauges in India reflects the country's industrial growth and need for accuracy in various sectors. With a focus on quality, innovation, and local manufacturing, the Indian pressure gauge industry is poised for further advancement. Companies that invest in high-quality pressure measurement solutions not only enhance their operational efficiency but also ensure safety and compliance in their processes. As industries continue to evolve, the role of precision pressure gauges will remain indispensable, driving the need for excellence in measurement technology across the nation.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025