dec . 04, 2024 19:59 Back to list

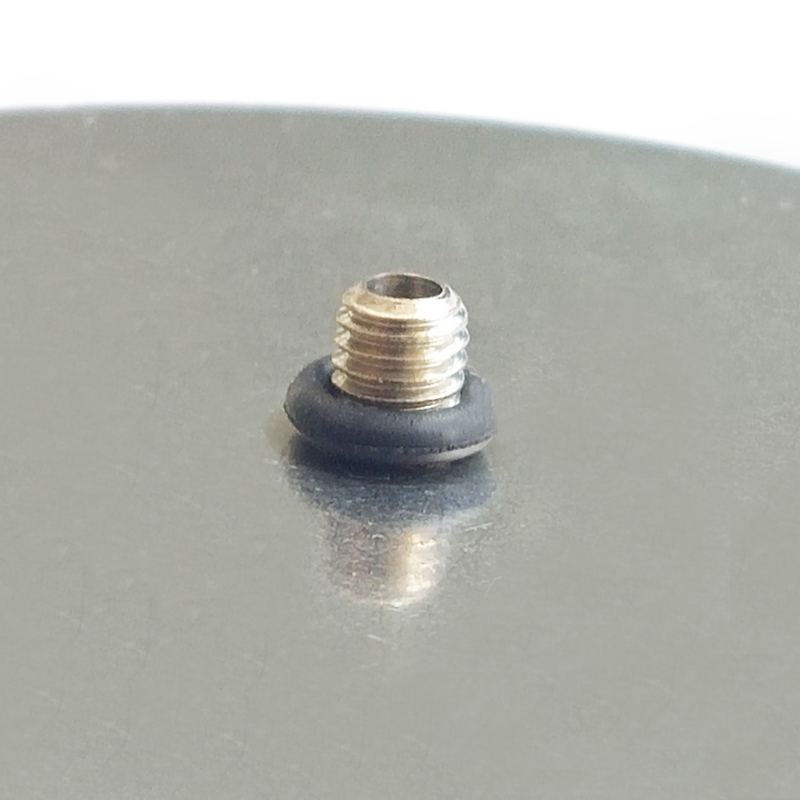

odm micro differential pressure gauge

Understanding the ODM Micro Differential Pressure Gauge

In various industrial applications, accurate measurement of pressure differences is critical for maintaining system integrity and ensuring optimal performance. One of the most effective tools for this purpose is the ODM Micro Differential Pressure Gauge. This instrument has gained prominence due to its precision, reliability, and versatility across multiple fields such as HVAC systems, cleanroom environments, and filtration processes.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference between two pressure points, providing essential data for monitoring system performance. Unlike standard pressure gauges that measure absolute pressure, differential gauges can detect small variations in pressure, enabling operators to make informed decisions about system health and efficiency. The ODM Micro Differential Pressure Gauge has been engineered to deliver high accuracy and responsiveness, making it an ideal choice for demanding applications.

Features and Benefits

1. High Precision One of the standout features of the ODM Micro Differential Pressure Gauge is its exceptional precision. It is designed to measure small pressure differences, often in the range of a few Pascals to several hundred Pascals. This capability is crucial in applications where even minor deviations can lead to significant repercussions.

2. Compact Design The Micro in its name refers to its compact form factor. This is particularly advantageous in constrained environments, where space is at a premium. The lightweight and small design also allow for easier installation and integration into existing systems without requiring extensive modifications.

3. Robust Construction The ODM Micro Differential Pressure Gauge is built to withstand challenging conditions. It is often made from durable materials resistant to corrosion and abrasion, ensuring longevity even in harsh environments. This reliability minimizes downtime and maintenance costs, ultimately enhancing operational efficiency.

4. User-Friendly Interface The gauge is equipped with an intuitive user interface that allows for easy reading of pressure differences. Some models feature digital displays that provide real-time data, enabling users to monitor conditions continuously. Such features facilitate rapid decision-making and incident response.

odm micro differential pressure gauge

5. Versatile Applications One of the most significant advantages of the ODM Micro Differential Pressure Gauge is its versatility. It can be utilized in a variety of applications, from monitoring filtration systems in cleanrooms to assessing pressure drops across HVAC filters. In the pharmaceutical and food industries, it helps ensure cleanliness and compliance with stringent regulatory standards by monitoring air and liquid flows.

Applications in Industry

1. HVAC Systems In HVAC applications, maintaining the right balance of pressure is crucial for efficient operation. The ODM Micro Differential Pressure Gauge aids in monitoring the differential pressure across filters and ducts, ensuring that systems operate within optimal parameters. This monitoring helps prevent failures and extends the lifespan of HVAC components.

2. Cleanroom Monitoring Cleanrooms require precise control over environmental conditions to prevent contamination. The ODM Micro Differential Pressure Gauge plays a vital role in maintaining the differential pressure between clean and non-clean areas, ensuring that pollutants do not enter sensitive spaces. Regular monitoring also helps conform to industry standards for cleanliness.

3. Filtration Processes In filtration systems, noticing a pressure drop across the filter elements is critical for performance assessment. The ODM Micro Differential Pressure Gauge measures these pressure differences accurately, allowing operators to determine when to change or clean filters, thus ensuring consistent quality and efficiency in operations.

4. Hydraulic Systems In hydraulic applications, pressure differentials can indicate potential failures within components. By monitoring these changes, operators can identify issues before they escalate, thereby enhancing system reliability and safety.

Conclusion

The ODM Micro Differential Pressure Gauge represents a significant advancement in pressure measurement technology. Its combination of precision, durability, and versatility makes it an invaluable tool in various industrial sectors. By effectively monitoring pressure differences, these gauges not only enhance operational efficiency but also ensure compliance with safety and quality standards. In an era where accuracy and reliability are paramount, the ODM Micro Differential Pressure Gauge stands out as an essential device for engineers and technicians alike.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025