aug . 17, 2024 01:52 Back to list

Types of Differential Pressure Gauges and Their Applications in Various Industries

Understanding Differential Pressure Gauge Types A Comprehensive Overview

Differential pressure gauges are essential instruments used in various industries to measure the pressure difference between two points in a system. These devices are critical in monitoring processes, ensuring operational efficiency, and safeguarding equipment. As technology has evolved, so too have the types of differential pressure gauges available on the market. This article explores the common types of differential pressure gauges and their applications.

1. Mechanical Differential Pressure Gauges

Mechanical differential pressure gauges are among the most traditional types of pressure measurement devices. They operate on the basic principle of a Bourdon tube, which changes shape in response to pressure differences. The main components include a flexible metal tube that twists under pressure, a gear mechanism, and a dial that displays the pressure reading.

These gauges are widely used in applications where electrical components might be unsuitable, such as in hazardous environments or where water and dust might affect performance. They are typically robust and can handle high-pressure differentials, making them ideal for various industrial applications, including HVAC systems and water treatment facilities.

2. Electronic Differential Pressure Gauges

Electronic differential pressure gauges have gained popularity due to their accuracy and ease of integration with modern control systems. These devices utilize sensors, such as piezoelectric or capacitive sensors, that convert pressure differences into electrical signals. The readings are then displayed digitally, allowing for improved precision and the ability to monitor changes in real-time.

This type of gauge is commonly found in industries that require precise measurements, such as pharmaceuticals, food processing, and semiconductor manufacturing. Their ability to interface with computer systems also makes them suitable for automated processes, enhancing data logging and monitoring capabilities.

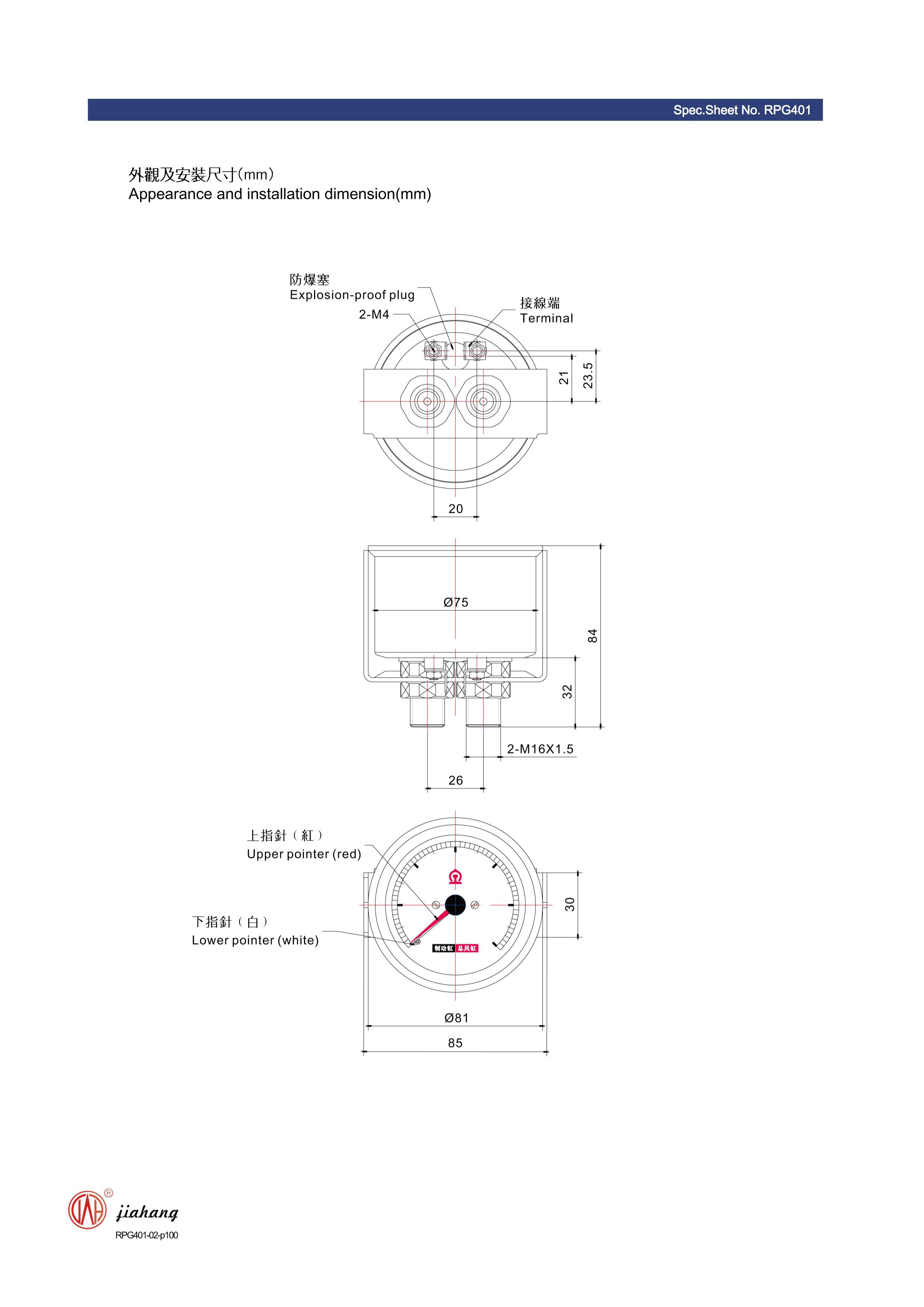

differential pressure gauge types jah

3. Wireless Differential Pressure Gauges

With the advancement of wireless technologies, wireless differential pressure gauges have emerged as a modern solution for pressure monitoring. These gauges, which often use Bluetooth or Wi-Fi to transmit data, enable remote monitoring of pressure differentials without the need for extensive wiring.

Wireless gauges are particularly advantageous in scenarios where continuous monitoring is required but running cables may be impractical or costly. Applications include oil and gas, environmental monitoring, and facilities management. They can provide real-time data access from anywhere, allowing for quicker decision-making and response times.

4. Differential Pressure Transmitters

Though not strictly a gauge, differential pressure transmitters are closely related devices that play a crucial role in pressure measurement. Unlike traditional gauges that display pressures, transmitters convert pressure differentials into standardized signals (usually 4-20 mA or digital outputs) used in control systems and automation.

Differential pressure transmitters are widely used in process industries, such as chemical plants, power generation, and HVAC systems, for monitoring flow rates, level, and pressure drops across filters or heat exchangers. Their versatility and accuracy make them indispensable tools in modern industrial applications.

Conclusion

Understanding the different types of differential pressure gauges is crucial for selecting the right instrument for a specific application. From mechanical gauges to sophisticated electronic transmitters, each type offers unique advantages tailored to diverse industrial needs. As processes become more automated and data-driven, the demand for accurate and reliable differential pressure measurement continues to grow, highlighting the importance of these essential instruments in maintaining efficiency and safety in various environments. Whether for monitoring, control, or safety purposes, differential pressure gauges play a pivotal role in the success of modern industry.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025