gru . 19, 2024 23:27 Back to list

aerosense differential pressure gauge

Understanding Aerosense Differential Pressure Gauges

In the realm of industrial measurement and control, differential pressure gauges play a crucial role in monitoring the pressure difference between two points in a system. One notable brand that is recognized for its reliable and advanced solutions is Aerosense. Their differential pressure gauges are widely used across various applications, ranging from HVAC systems to process engineering.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. This type of instrument is essential in numerous industries, including aerospace, pharmaceutical, food and beverage, and water treatment. By understanding the pressure differential, engineers can assess system performance, ensure safety, and maintain optimal operating conditions.

Aerosense differential pressure gauges provide precise readings that help in detecting malfunctions or inefficiencies in systems. For example, in an HVAC system, a differential pressure gauge can help determine if an air filter is clogged. A significant increase in pressure differential indicates that the filter needs replacement, thus allowing for timely maintenance and preventing system failure.

Features of Aerosense Differential Pressure Gauges

Aerosense offers a variety of differential pressure gauges that come equipped with advanced features designed to enhance performance and usability. Some notable features include

1. High Accuracy Aerosense gauges are calibrated for high precision, ensuring that the readings are reliable and consistent. This accuracy is critical, especially in applications where slight variations in pressure can lead to significant performance issues.

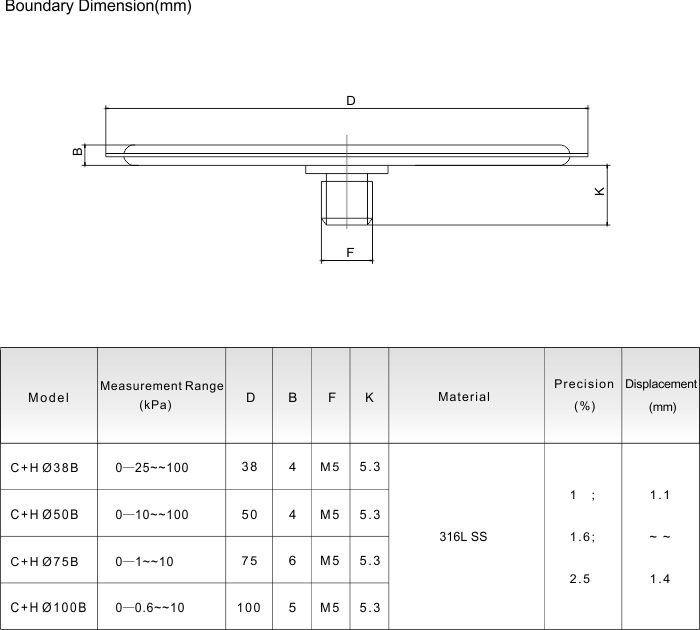

2. Wide Measurement Range These gauges are available in different models to measure a broad range of pressure differentials. Whether it's low-pressure applications or high-pressure systems, Aerosense has suitable options to meet varying needs.

aerosense differential pressure gauge

3. Robust Construction Designed for durability, Aerosense differential pressure gauges are built to withstand harsh environments. They can resist vibrations, temperature fluctuations, and corrosive substances, making them ideal for industrial settings.

4. User-Friendly Interface Many of the gauges include easy-to-read dials or digital displays that provide a clear view of the pressure readings. This design enhances usability, allowing operators to quickly assess system conditions.

5. Versatile Applications Aerosense gauges can be utilized in a wide array of applications, including measuring flow rates in piping systems, monitoring filter conditions, and ensuring proper air balance in ventilation systems.

Importance in Industrial Systems

The role of differential pressure gauges cannot be overstated, as they are instrumental in ensuring the efficiency and safety of industrial processes. By providing real-time data on the pressure difference, these gauges help operators take immediate actions when inconsistencies arise. This capability is vital in preventing downtime, minimizing repair costs, and enhancing overall productivity.

In the aerospace industry, for instance, maintaining a specific pressure differential is critical for engine performance and safety. Differential pressure gauges ensure that parameters are monitored and controlled, contributing to the safe and efficient operation of aircraft.

Conclusion

Aerosense differential pressure gauges exemplify the intersection of technology and engineering, providing a reliable solution for pressure measurement across various industries. Their accuracy, robust design, and user-friendly features make them a preferred choice for professionals seeking to enhance their operational efficiency. As industries continue to evolve, the demand for precise pressure monitoring solutions like those offered by Aerosense will undoubtedly grow, paving the way for advancements in operational safety and performance.

In summary, understanding the functionalities and applications of differential pressure gauges is vital for professionals in the field. Whether in maintaining HVAC systems or ensuring the efficiency of complex manufacturing processes, Aerosense differential pressure gauges stand out as an indispensable tool in modern industrial measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025