wrz . 07, 2024 04:45 Back to list

High-Precision Capacitance Diaphragm Pressure Gauges for Accurate Measurements

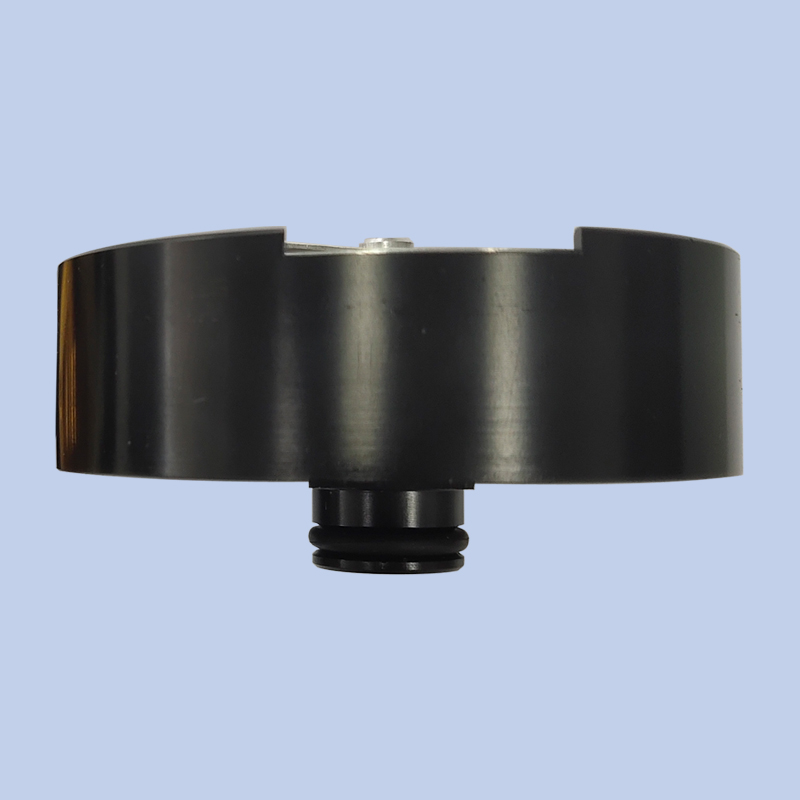

Understanding Capacitance Diaphragm Pressure Gauge Products

Capacitance diaphragm pressure gauges are sophisticated instruments widely utilized in various industries to measure the pressure of gases or liquids. These devices offer a high level of accuracy and reliability, making them essential for applications ranging from process control in chemical plants to monitoring systems in aerospace engineering.

The core of a capacitance diaphragm pressure gauge is its sensing element, typically a thin diaphragm made from a flexible material. When pressure is applied to the diaphragm, it deflects, causing a change in capacitance between the diaphragm and a fixed electrode. This change in capacitance is then converted into an electrical signal, which can be calibrated and displayed in pressure readings. The advantages of this technology include a high sensitivity to pressure changes, excellent linearity, and good resistance to temperature variations.

One of the primary benefits of capacitance diaphragm pressure gauges is their ability to maintain performance across a wide range of pressures. These gauges are suitable for both low and high pressure measurements, making them versatile for many different applications. Furthermore, their design often allows for minimal maintenance and long-term stability, which is critical for industries where equipment downtime can result in significant losses.

capacitance diaphragm pressure gauge products

Capacitance diaphragm pressure gauges can be used in a variety of environments, including those that involve corrosive substances. By using specialized materials, such as stainless steel or various polymers, manufacturers can produce gauges that withstand harsh conditions without compromising accuracy. Additionally, some models offer options for overpressure protection, making them even more robust for demanding applications.

In terms of installation and use, capacitance diaphragm pressure gauges are generally straightforward. They can typically be integrated into existing systems with minimal modifications. Once installed, users can monitor pressure levels in real-time, allowing for prompt responses to any fluctuations that may occur. This real-time monitoring capability is particularly beneficial in critical processes where maintaining specific pressure levels is vital for safety and efficiency.

Moreover, advancements in digital technology have allowed for the development of smart capacitance diaphragm pressure gauges. These modern devices can connect to networks and provide data logging features, remote monitoring capabilities, and alerts for abnormal pressure levels. This connectivity is increasingly essential in today’s industrial environments, where data analytics play a crucial role in optimizing operations and enhancing safety measures.

In conclusion, capacitance diaphragm pressure gauge products represent a vital component in pressure measurement technology. Their accuracy, reliability, and versatility make them indispensable across various industries, ensuring processes run smoothly and safely. Whether used in traditional applications or modern smart manufacturing setups, these gauges continue to evolve and meet the demanding needs of today's technological landscape.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025