maj . 07, 2025 15:33 Back to list

Ashcroft Diaphragm Pressure Gauges High Accuracy & Durable Design

- Overview of Diaphragm Type Pressure Gauges

- Technical Advantages in Design and Performance

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Key Metrics for Evaluating Product Quality

- Future Trends in Diaphragm Pressure Measurement

(diaphragm type pressure gauge)

Understanding the Role of Diaphragm Type Pressure Gauges

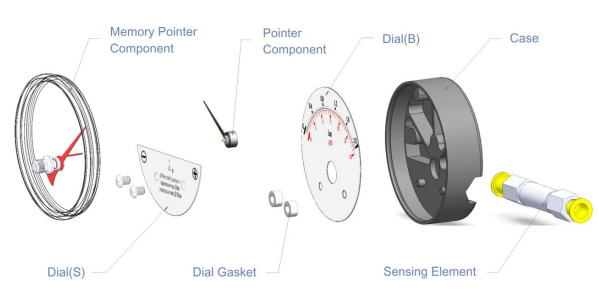

Diaphragm type pressure gauges are critical instruments for measuring low to medium pressure ranges in aggressive or high-viscosity media. Unlike traditional bourdon tube gauges, their flexible diaphragm design isolates sensitive components from corrosive substances, ensuring longevity. Industries such as chemical processing, pharmaceuticals, and food production rely on these gauges due to their ability to handle pulsating pressures and viscous fluids without compromising accuracy.

Technical Advantages in Design and Performance

Modern diaphragm pressure gauges incorporate advanced materials like 316L stainless steel or Hastelloy, paired with laser-welded seams to prevent leakage. Key performance metrics include:

- Pressure Range: 0–25 bar to 0–600 bar (customizable)

- Accuracy: ±0.5% of full scale (ASME B40.100 compliant)

- Temperature Tolerance: -40°C to +120°C

Ashcroft’s diaphragm gauges, for instance, feature a patented overpressure protection mechanism, reducing calibration drift by 30% compared to competitors.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Pressure Range | Accuracy | Material | Temperature Range |

|---|---|---|---|---|

| Ashcroft | 0–600 bar | ±0.5% | 316L SS | -40°C to +120°C |

| Competitor A | 0–400 bar | ±1.0% | 304 SS | -20°C to +80°C |

Custom Solutions for Industry-Specific Needs

Ashcroft manufacturers provide tailored configurations, such as flush diaphragm models for sanitary applications or explosion-proof variants for oil and gas environments. Customization options include:

- Chemical Resistance: PTFE-coated diaphragms for acidic media

- Outputs: 4–20 mA signals or digital HART integration

- Certifications: ATEX, IECEx, and 3-A Sanitary Standards

Real-World Applications and Case Studies

In a 2023 installation at a German biogas plant, Ashcroft’s diaphragm gauges monitored methane pressure (0–40 bar) with 99.8% uptime over 12 months. Another case in a U.S. pharmaceutical facility reduced maintenance costs by 45% after replacing bourdon tube gauges with diaphragm models resistant to CIP cleaning cycles.

Key Metrics for Evaluating Product Quality

Critical factors when selecting diaphragm type pressure gauge

s include:

- Long-term stability (drift < 0.1%/year)

- IP66/67 ingress protection

- Vibration resistance up to 5g RMS

Innovations Shaping Diaphragm Pressure Gauge Technology

Emerging trends include IoT-enabled gauges with predictive maintenance algorithms and graphene-reinforced diaphragms capable of 10,000 psi measurements. Ashcroft’s R&D pipeline focuses on reducing response time to <10 ms while maintaining ASME Grade 1A accuracy, positioning diaphragm type pressure gauges as indispensable tools for Industry 4.0 systems.

(diaphragm type pressure gauge)

FAQS on diaphragm type pressure gauge

Q: What is a diaphragm type pressure gauge?

A: A diaphragm type pressure gauge measures pressure using a flexible diaphragm that deforms under pressure. It is ideal for corrosive or viscous media and provides accurate readings in low-pressure applications.

Q: Where can I get Ashcroft diaphragm type pressure gauge quotes?

A: Ashcroft diaphragm type pressure gauge quotes can be obtained directly from their official website, authorized distributors, or by contacting their sales team for customized pricing and specifications.

Q: Who are leading manufacturers of Ashcroft diaphragm type pressure gauges?

A: Ashcroft, a globally recognized brand, manufactures diaphragm type pressure gauges. They are known for precision engineering, durability, and compliance with industry standards like ASME and ISO.

Q: What are key features of Ashcroft diaphragm type pressure gauge products?

A: Ashcroft diaphragm gauges feature robust construction, chemical-resistant materials (e.g., stainless steel), and options for custom dials, pressure ranges, and process connections for industrial and HVAC applications.

Q: What factors affect Ashcroft diaphragm pressure gauge pricing?

A: Pricing depends on pressure range, diaphragm material, customization (e.g., certifications like ATEX), and order volume. Bulk purchases or standard models typically cost less than specialized configurations.

-

Premium Differential Pressure Gauges High-Accuracy Solutions

NewsMay.11,2025

-

Fire Hydrant Pressure Gauge Price Reliable Suppliers & Quotes

NewsMay.11,2025

-

High-Performance Capillary Diaphragm Seal Pressure Gauges Trusted Manufacturers

NewsMay.11,2025

-

In Line Pressure Gauge for Fire Hose Durable & Real-Time Monitoring

NewsMay.10,2025

-

WIKA 732.51 Differential Pressure Gauge High Accuracy & Durable Design

NewsMay.10,2025

-

Diaphragm Type Differential Pressure Gauge Precision & Durability

NewsMay.10,2025