lis . 29, 2024 15:59 Back to list

Differential Pressure Gauge Kit Supplier for Accurate Measurement Solutions and Applications

The Importance of Differential Pressure Gauge Kits and Their Manufacturers

In the world of industrial measurement, accuracy and reliability are paramount. One of the critical instruments used for measuring pressure differences is the differential pressure gauge. Differential pressure gauges play an essential role in various applications, including HVAC systems, filtration monitoring, and liquid level measurement. As such, the manufacturers of differential pressure gauge kits have become invaluable partners in ensuring operational efficiency and safety in numerous industries.

Understanding Differential Pressure Gauges

Differential pressure gauges measure the difference in pressure between two points in a system. Unlike standard pressure gauges that measure absolute pressure, differential gauges are specifically designed to provide readings that indicate how much higher or lower the pressure is at one point compared to another. This functionality is crucial for processes that require maintaining specific pressure conditions to ensure optimal operation.

Applications of differential pressure gauges include monitoring air filters, liquid level detection, and ensuring correct pressure drops across valves and other equipment. In HVAC systems, for instance, these gauges are used to gauge airflow and maintain energy efficiency. In filtration systems, they help in monitoring filter integrity and performance, alerting operators when filters need to be changed to prevent system inefficiencies.

The Role of Manufacturers

Given the critical nature of these gauges, the manufacturers of differential pressure gauge kits are tasked with producing highly reliable instruments that meet various industry standards. High-quality manufacturing processes and materials are essential to ensure the accuracy and durability of these gauges. Manufacturers focus on several key factors in their production

1. Quality Control Manufacturers implement rigorous quality control measures throughout the production process. This includes testing gauges under different conditions to ensure their performance aligns with industry standards.

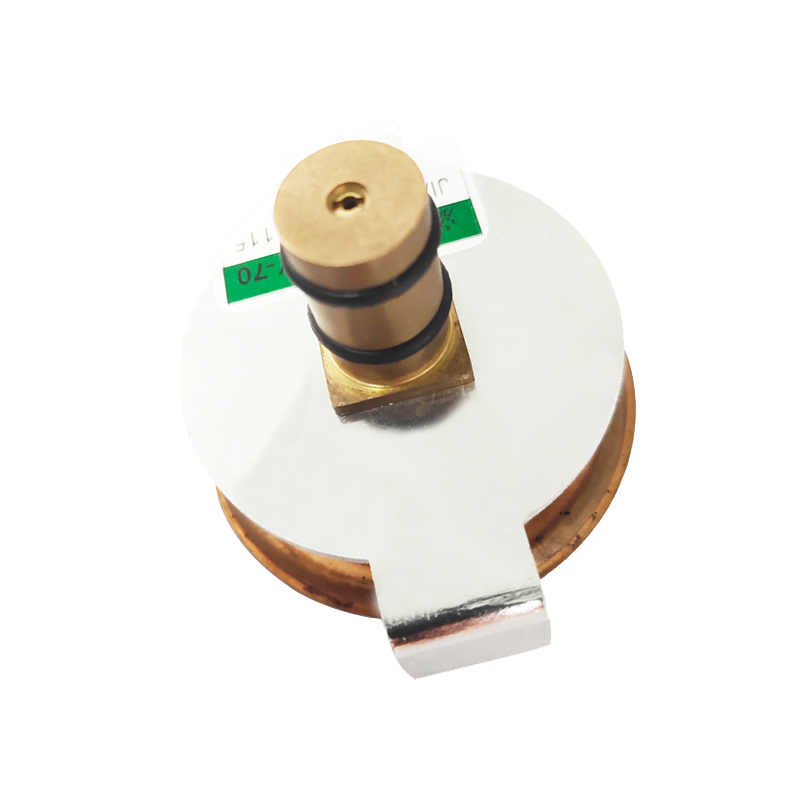

differential pressure gauge kit manufacturer

2. Customization Depending on the specific applications and environments where the gauges will be used, manufacturers often offer customization options. Clients may require certain pressure ranges, materials that resist corrosion, or specific mounting configurations.

3. Technology Integration With advancements in technology, many manufacturers are now offering smart differential pressure gauges. These gauges integrate digital displays, data logging capabilities, and connectivity options for remote monitoring. Such features are essential for modern industrial applications, allowing for real-time data analysis and process management.

4. Support and Training Beyond product offerings, reputable manufacturers provide excellent customer support and training services. They help clients understand how to install, calibrate, and maintain their differential pressure gauge kits, ensuring that users can maximize the performance of these essential tools.

Selecting the Right Manufacturer

When choosing a manufacturer for differential pressure gauge kits, it's crucial to consider several factors. Firstly, one should evaluate the manufacturer's reputation in the industry, which can often be gauged through customer reviews and case studies. Additionally, assessing the range of products offered, after-sales support, and warranty policies can provide insight into the reliability and service quality of the manufacturer.

Moreover, ensuring that the manufacturer complies with relevant industry standards, such as ISO certifications, can offer peace of mind regarding the quality and performance of the gauges.

Conclusion

In conclusion, differential pressure gauges are vital tools in a myriad of industrial applications, ensuring processes run smoothly and efficiently. The manufacturers of these gauge kits play a crucial role in delivering reliable and technically advanced products that meet the demands of diverse industries. By focusing on quality, customization, and customer support, these manufacturers are not only contributing to operational efficiency but are also enhancing safety standards across various sectors. As technology continues to evolve, so too will the offerings of differential pressure gauge manufacturers, paving the way for even greater advancements in measurement and monitoring in the industrial landscape.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025