lis . 24, 2024 03:43 Back to list

fire pump pressure gauge

Understanding Fire Pump Pressure Gauges Importance, Types, and Maintenance

In the realm of fire protection systems, fire pump pressure gauges play a critical role in ensuring that firefighting efforts are both effective and efficient. A fire pump is designed to deliver water at a specific pressure needed to combat fires, and pressure gauges are essential tools that provide vital information about the operational performance of these systems. This article explores the importance of fire pump pressure gauges, the different types available, and maintenance practices to ensure their longevity and accuracy.

The Importance of Fire Pump Pressure Gauges

Fire pump pressure gauges serve a pivotal function in monitoring the pressure of water being delivered by the fire pump to the fire protection system. The pressure readings from these gauges allow firefighters to determine whether the pump is operating within the acceptable range. If the pressure is too low, it can indicate that the pump is not delivering enough water to suppress a fire, potentially leading to catastrophic consequences. Conversely, excessively high pressure can damage hoses and nozzles, making them ineffective or dangerous to use.

Furthermore, pressure gauges help in diagnosing issues with the fire pump. By consistently monitoring pressure levels, maintenance personnel can identify irregularities indicating a malfunction or the need for repairs. This proactive approach helps in maintaining the reliability of fire protection systems, ensuring they are ready to respond in emergencies.

Types of Fire Pump Pressure Gauges

There are several types of pressure gauges used in fire pump systems, each with its own advantages and applications

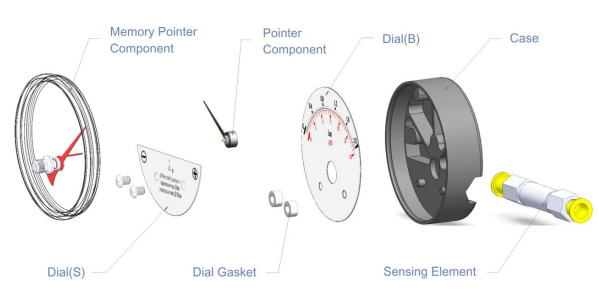

1. Mechanical Pressure Gauges These gauges operate using a physical mechanism that responds to changes in pressure. They typically feature a dial display, with a needle indicating the current pressure. Mechanical gauges are reliable, require no external power source, and are easy to read. They are suitable for many fire pump applications.

2. Digital Pressure Gauges Unlike mechanical gauges, digital pressure gauges provide electronic readings on a digital display. They can offer more precise measurements and are often equipped with features such as data logging, alarms, and connectivity options. Digital gauges can be more expensive but may provide additional functionalities that can be beneficial in complex fire protection systems.

3. Differential Pressure Gauges These gauges measure the difference in pressure between two points in a system. They are particularly useful for monitoring pressure drops across filters or between the inlet and outlet of the pump. By identifying pressure differentials, maintenance teams can detect blockages or obstructions that may hinder performance.

fire pump pressure gauge

4. Compound Gauges These gauges can measure both positive and negative pressure, making them versatile for various applications. They are often used in applications where a vacuum is also present, allowing for comprehensive monitoring of the pump's performance.

Maintenance of Fire Pump Pressure Gauges

Maintaining fire pump pressure gauges is essential to ensure their accuracy and reliability. Here are some best practices for gauge maintenance

1. Regular Inspections Schedule routine inspections to check the condition and accuracy of the gauges. Look for signs of damage, such as leaks, cracks, or corrosion. Any damaged gauge should be replaced immediately.

2. Calibration Periodic calibration is crucial for maintaining the accuracy of pressure gauges. They should be calibrated against a known reliable pressure source to ensure their readings are correct.

3. Cleaning Dust and debris can accumulate on gauges, potentially obstructing the readings. Regular cleaning with a soft cloth can help maintain visibility and accuracy. Ensure that any cleaning agents used do not harm the gauge material.

4. Proper Installation Ensure that the pressure gauges are installed according to the manufacturer's specifications. Incorrect installation can result in improper readings or damage to the gauges.

5. Documentation Keep records of all inspections, maintenance, and calibrations performed on the pressure gauges. This documentation can be crucial for compliance and for understanding the history of the fire pump system.

Conclusion

Fire pump pressure gauges are indispensable tools in the fire protection industry, providing critical data that ensures the effectiveness and safety of firefighting efforts. Understanding the different types of gauges available and implementing a robust maintenance routine can help prolong their lifespan and functionality. By prioritizing the health of fire pump pressure gauges, facilities can enhance their fire protection systems, ensuring they are ready to respond effectively in the event of an emergency.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025