sie . 17, 2024 06:06 Back to list

Precision Square Root Differential Pressure Gauge for Accurate Measurements

High-Quality Square Root Differential Pressure Gauges Essential Tools in Process Measurement

In the realm of process control and measurement, differential pressure gauges play a crucial role in monitoring and maintaining system performance. Among the various types available, high-quality square root differential pressure gauges stand out for their precision and reliability, making them essential tools across numerous industries, including oil and gas, water treatment, and chemical manufacturing.

Understanding Differential Pressure Gauges

Differential pressure gauges measure the difference between two pressure points in a system. This measurement is critical for various applications, such as flow measurement, level measurement, and filter monitoring. The square root differential pressure gauge, specifically, takes this a step further by providing readings proportional to the square root of the differential pressure, a relationship that is particularly useful in flow measurement applications. This attribute allows users to derive flow rates directly from the pressure differential readings, enhancing measurement accuracy and efficiency.

The Significance of High-Quality Gauges

Quality is paramount when it comes to pressure measurement instruments. High-quality square root differential pressure gauges are designed to withstand extreme conditions, including temperature fluctuations, corrosive environments, and high pressures. These gauges are constructed using durable materials and advanced technology to ensure longevity and reliability.

One of the significant advantages of investing in high-quality gauges is their accuracy. Accurate measurements are critical for maintaining process efficiency, ensuring safety, and reducing operational costs. In industries where precision is paramount, even a slight deviation in pressure readings can lead to catastrophic results, making high-quality instrumentation a non-negotiable requirement.

The Working Principle

The working principle of a square root differential pressure gauge is based on the fundamental physics of fluid dynamics. When a fluid flows through a pipe, it creates pressure differentials due to resistance caused by changes in velocity or flow area. The gauge uses this differential pressure signal, typically from a differential pressure transmitter, to compute the square root value, which corresponds to the flow rate in the system.

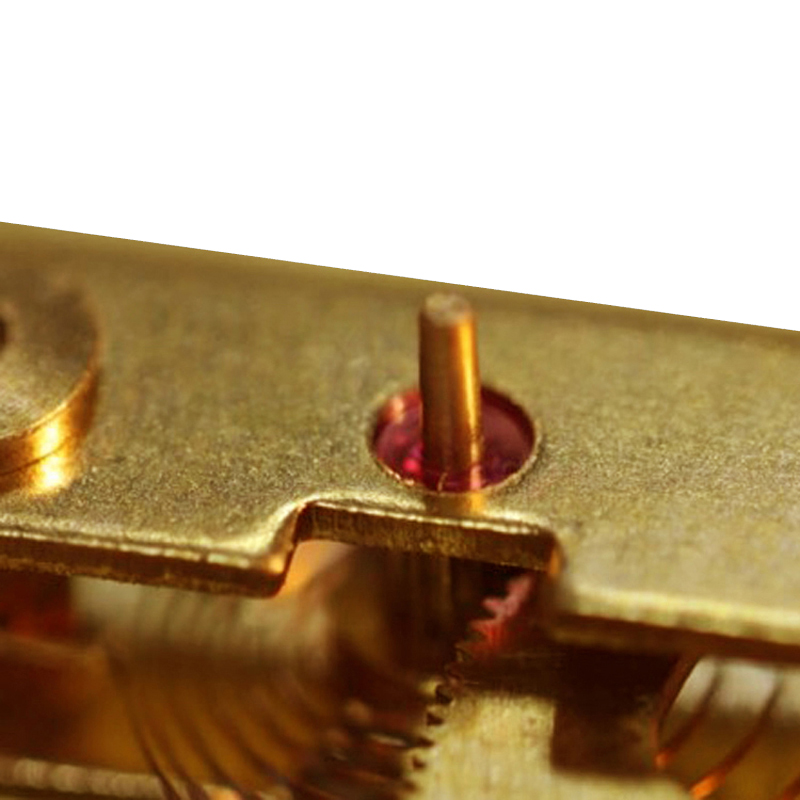

high quality square root differential pressure gauge

This relationship is mathematically described by the equation

\[ Q = K \sqrt{\Delta P} \]

where \( Q \) is the flow rate, \( K \) is a constant depending on the fluid and system, and \( \Delta P \) is the differential pressure. This formula exemplifies how utilizing high-quality square root differential pressure gauges can lead to more efficient and accurate flow measurements in various applications.

Applications and Benefits

High-quality square root differential pressure gauges find applications in several critical areas. In the petrochemical industry, they are used to monitor flow rates in pipelines, ensuring that operations maintain a steady and safe flow. In water treatment facilities, these gauges monitor filter performance, signaling the need for maintenance before issues lead to costly downtime.

Apart from their reliability and accuracy, these gauges offer additional benefits such as ease of installation and low maintenance requirements. Many high-quality models are designed for easy integration into existing systems, providing users with flexibility and convenience. Additionally, advancements in technology have made digital square root differential pressure gauges available, offering enhanced features such as data logging, remote monitoring, and alarm systems for improved operational oversight.

Conclusion

In conclusion, high-quality square root differential pressure gauges are indispensable instruments in the modern industrial landscape. Their accuracy, reliability, and ease of use make them essential for efficient process measurement and control. By investing in such gauges, industries can ensure optimal performance, reduce the risk of failure, and enhance overall safety and productivity. As technology continues to advance, the capabilities and applications of these gauges will only expand, further solidifying their importance in various sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025