Fev . 15, 2025 08:11 Back to list

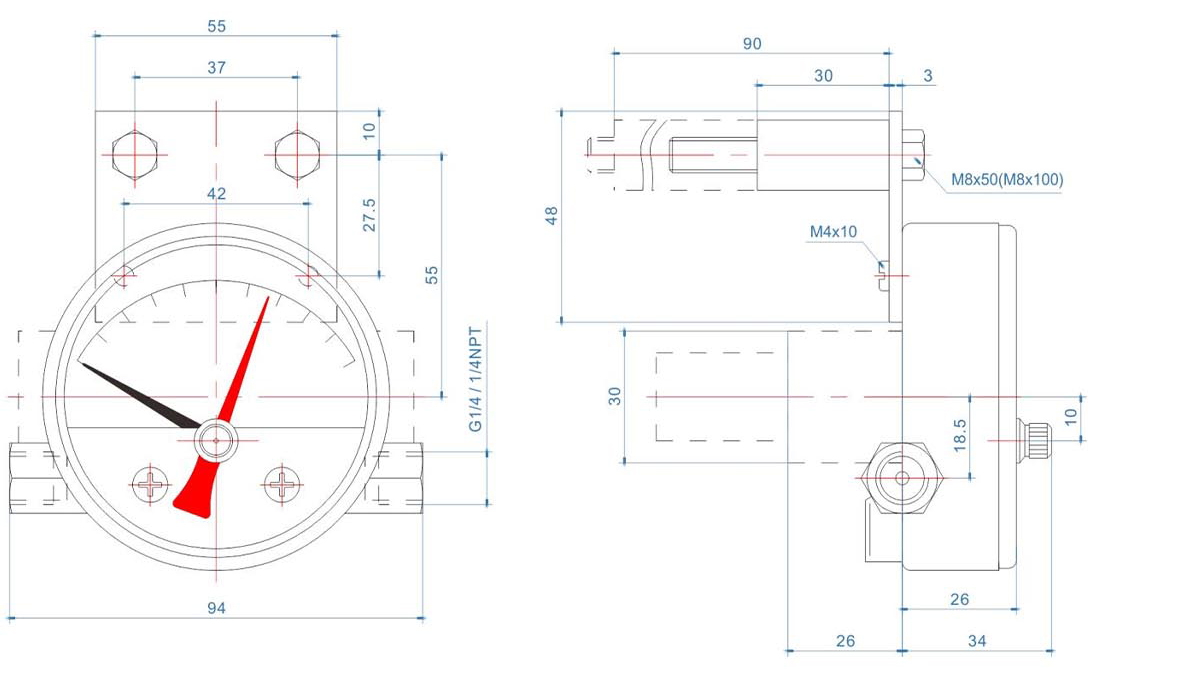

Diaphragm Capsule Pressure Gauge(CPG)-Medical Type (Night Vision) YEY-50

Crafting a different pressure gauge using DIY methods in China can be both an exciting and rewarding experience. Not only does it give you hands-on knowledge of mechanical and electronic systems, but it also empowers you to customize a tool that fits your exact measurement needs. This guide brings together a wealth of expertise, practical experience, and the latest methods to ensure you successfully create a reliable pressure gauge.

3. Microcontroller Setup Connect your transducers to the microcontroller. This is the brain of your gauge. You'll need to program it to convert the electronic signals from the transducers into readable data that calculates the pressure difference. 4. Display Integration Connect the microcontroller to your chosen display module. Ensure that the display accurately reflects the calculated pressure differences and adjust the programming if necessary for any discrepancies. 5. System Calibration Before use, conduct thorough calibration with a known pressure source. Adjust your system to ensure that your readings are accurate across a range of values. Calibration should be conducted regularly or whenever the gauge is moved or altered. Benefits of DIY Differential Pressure Gauges Building your own differential pressure gauge allows for tailored specificity and understanding it at a fundamental level ensures more meaningful interactions and diagnostics with your systems. This process also fosters innovation by encouraging users to understand and implement personalized improvements or adaptations for varied applications. Building Trust and Authority To ensure trustworthiness, when creating and using a DIY gauge, always adhere to safety standards and guidelines. Using reputable brands for parts and keeping up-to-date with technological advancements elevates the reliability of your instrument. Building a strong foundation of knowledge through industry forums, expert advice, and peer-reviewed sources also solidifies the authoritativeness of your gauge. Concluding Thoughts In conclusion, creating a DIY differential pressure gauge in China blends skill, knowledge, and creativity. This endeavor not only saves cost but also enhances personalized applications within various environments. By meticulously following the outlined steps and utilizing the right tools, one can craft a precise and dependable device for numerous applications. With ongoing practice and updates in technique, this DIY project can evolve as a lasting contribution to both personal growth and professional proficiency in pressure measurement technology.

3. Microcontroller Setup Connect your transducers to the microcontroller. This is the brain of your gauge. You'll need to program it to convert the electronic signals from the transducers into readable data that calculates the pressure difference. 4. Display Integration Connect the microcontroller to your chosen display module. Ensure that the display accurately reflects the calculated pressure differences and adjust the programming if necessary for any discrepancies. 5. System Calibration Before use, conduct thorough calibration with a known pressure source. Adjust your system to ensure that your readings are accurate across a range of values. Calibration should be conducted regularly or whenever the gauge is moved or altered. Benefits of DIY Differential Pressure Gauges Building your own differential pressure gauge allows for tailored specificity and understanding it at a fundamental level ensures more meaningful interactions and diagnostics with your systems. This process also fosters innovation by encouraging users to understand and implement personalized improvements or adaptations for varied applications. Building Trust and Authority To ensure trustworthiness, when creating and using a DIY gauge, always adhere to safety standards and guidelines. Using reputable brands for parts and keeping up-to-date with technological advancements elevates the reliability of your instrument. Building a strong foundation of knowledge through industry forums, expert advice, and peer-reviewed sources also solidifies the authoritativeness of your gauge. Concluding Thoughts In conclusion, creating a DIY differential pressure gauge in China blends skill, knowledge, and creativity. This endeavor not only saves cost but also enhances personalized applications within various environments. By meticulously following the outlined steps and utilizing the right tools, one can craft a precise and dependable device for numerous applications. With ongoing practice and updates in technique, this DIY project can evolve as a lasting contribution to both personal growth and professional proficiency in pressure measurement technology.

Share

Latest news

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025

-

Wika Diaphragm Seal Pressure Gauge High-Accuracy & Durable Solutions

NewsMay.18,2025

-

Diaphragm Type Differential Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.17,2025

-

Bellow Type Differential Pressure Gauge High Accuracy & Durable Design

NewsMay.17,2025

-

WIKA 700.04 Differential Pressure Gauge Precision Industrial Measurement

NewsMay.17,2025