Nov . 02, 2024 07:10 Back to list

custom bellow type differential pressure gauge

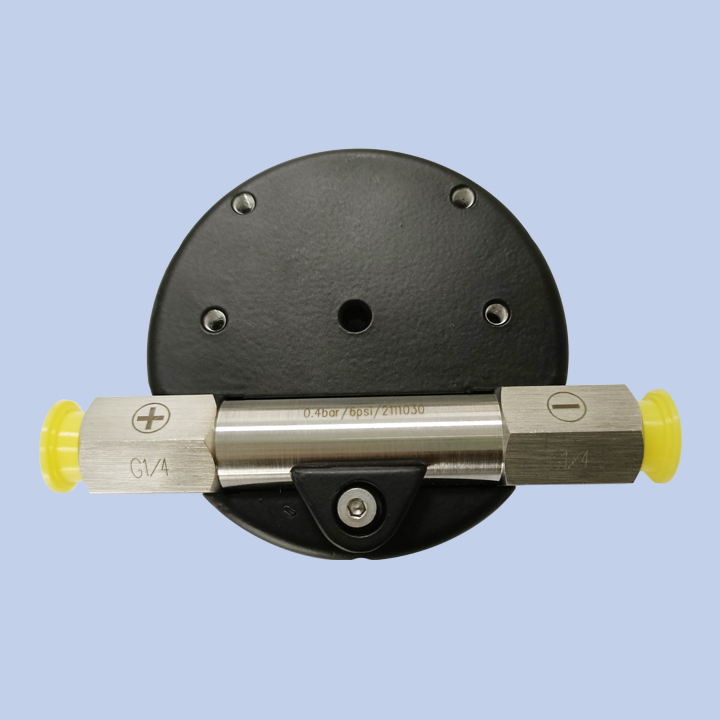

Custom Below Type Differential Pressure Gauge An Overview

In industrial applications, the measurement of pressure differences is crucial for ensuring processes operate efficiently and safely. One of the key instruments used for this purpose is the differential pressure gauge. Among the various types available, the custom below type differential pressure gauge has gained significant attention due to its unique design and functionality. This article explores the features, benefits, and applications of the custom below type differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points in a system. It is essential for monitoring processes in various industries, including oil and gas, pharmaceuticals, water treatment, and HVAC systems. The accurate measurement of pressure differences helps in detecting blockages, monitoring filter conditions, and ensuring that equipment operates within safe pressure limits.

Features of Custom Below Type Differential Pressure Gauge

The custom below type differential pressure gauge is specifically designed with certain features that distinguish it from standard models. One of the key characteristics is its mounting position. Unlike traditional gauges that are mounted above the measurement points, the custom below type is installed below, which can facilitate easier reading and access in specific applications. This design not only enhances visibility but can also improve the overall efficiency of the system.

Additionally, these gauges are often tailored to meet specific requirements of the industry or application. Customization can include varying materials of construction, size, measurement ranges, and other attributes that help meet the needs of particular operating environments. For instance, gauges can be constructed from corrosion-resistant materials for applications involving corrosive fluids, or be designed to withstand high temperatures for use in industries like petrochemicals.

Benefits of Using Custom Below Type Differential Pressure Gauge

custom bellow type differential pressure gauge

One of the primary benefits of using custom below type differential pressure gauges is their versatility. With the ability to tailor gauges to specific applications, companies can ensure accurate measurements regardless of the unique conditions they face. This enhances reliability and overall efficiency in operations.

Moreover, these gauges can contribute to improved safety. By accurately monitoring the pressure conditions within a system, potential issues such as blockages or leaks can be detected early, allowing for preventive measures to be taken. This is crucial in industries where pressure imbalances can lead to catastrophic failures.

Another advantage is the ease of installation and maintenance. The below mounting design often allows for easier installation in confined spaces, reducing the time and labor involved. Furthermore, maintenance can be simplified, as the positioning allows for better access to the gauge for routine checks or adjustments.

Applications

Custom below type differential pressure gauges find applications across various sectors. In the oil and gas industry, they are used to monitor pressure differences in pipelines to ensure efficient flow and detect any leaks. In HVAC systems, these gauges help maintain proper air flow and filter performance by measuring pressure drops across filters. In water treatment facilities, they are essential for ensuring that systems operate within safe pressure parameters.

Conclusion

In summary, the custom below type differential pressure gauge is an invaluable tool in various industrial applications. Its unique design, coupled with the ability to customize to meet specific needs, enhances measurement accuracy, safety, and operational efficiency. As industries continue to evolve and require more precise control over their processes, the importance of such specialized instruments will only increase.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025