Ago . 19, 2024 12:21 Back to list

Diaphragm Seal Manufacturing Services for Pressure Gauge Applications and Solutions

The Role of Pressure Gauge Diaphragm Seal Manufacturers in Ensuring System Integrity

In industrial applications, pressure measurement and monitoring are crucial for maintaining operational efficiency and safety. One of the vital components in the accurate reading of pressure is the diaphragm seal, particularly in environments where direct contact between the pressure sensor and the media is not feasible. Pressure gauge diaphragm seals are essential for protecting instruments from corrosive, viscous, or high-temperature substances. As industries evolve, the demand for quality diaphragm seals has led to the emergence of numerous manufacturers specializing in this technology.

Understanding Diaphragm Seals

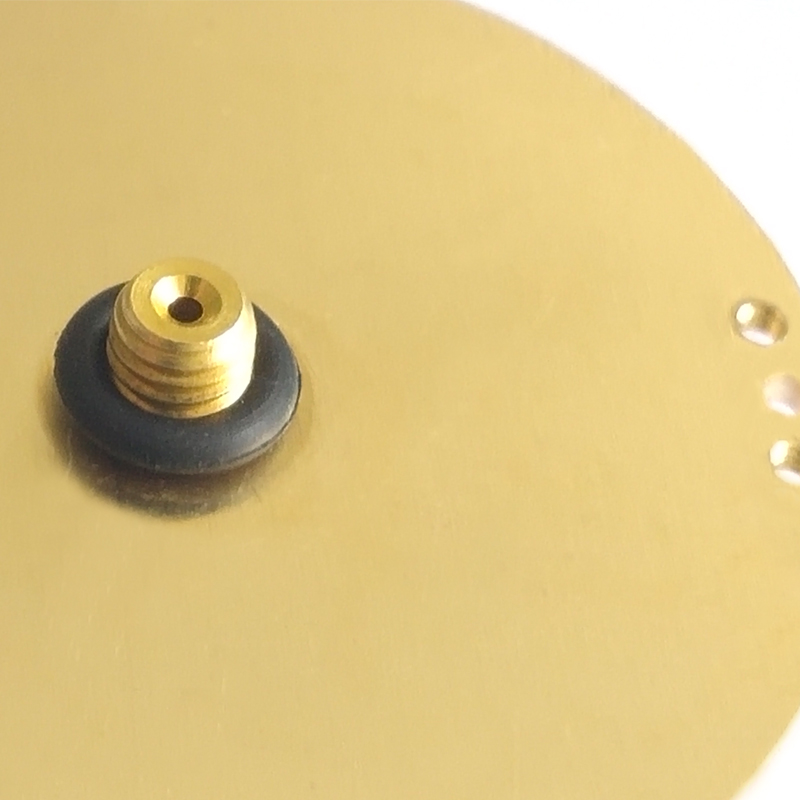

A diaphragm seal acts as a barrier between a pressure gauge and the process fluid. It consists of a flexible diaphragm that deforms under pressure, transmitting the force to the instrument. This design prevents the corrosive or viscous fluids from damaging the pressure gauge, thus enhancing its lifespan and reliability. The seals are essential in various industries, including oil and gas, chemical processing, pharmaceuticals, and food manufacturing, where integrity and hygiene are paramount.

Manufacturers' Services and Expertise

Manufacturers of pressure gauge diaphragm seals provide comprehensive services that extend beyond mere production. These services include

1. Customization Different applications require unique solutions. Manufacturers often work closely with clients to design custom diaphragm seals that meet specific pressure ranges, material compatibility, and environmental conditions. This customization ensures optimal performance and longevity.

2. Material Selection The choice of materials is crucial in the manufacturing of diaphragm seals. Leading manufacturers offer a range of options, from stainless steel to exotic alloys and elastomers that can withstand varying temperatures and chemical exposures. Expertise in material science allows manufacturers to recommend the best solutions for any given application.

pressure gauge diaphragm seal manufacturers service

3. Testing and Quality Assurance Reputable manufacturers implement rigorous testing protocols to ensure their products meet industry standards and performance expectations. This includes pressure testing, material integrity assessments, and durability evaluations. Ensuring high-quality outputs contributes to the overall reliability of the pressure measurement systems.

4. Technical Support Guidance and support from manufacturers can significantly improve system performance. They often provide technical documentation, installation guides, and troubleshooting assistance, empowering operators to achieve better results with the products.

5. After-Sales Service Manufacturers understand that the relationship with clients does not end with the sale. After-sales services, including maintenance programs and replacement parts, are critical for ensuring the long-term success of pressure gauge diaphragm seals.

Challenges and Innovations

While diaphragm seals play a critical role in various applications, manufacturers face challenges such as the need for continuous innovation to address evolving industry demands. The push for cleaner and more sustainable technologies drives developments in seal materials and designs. Manufacturers are now incorporating advanced materials with enhanced properties, such as increased chemical resistance and reduced friction.

Moreover, digital technologies are making their way into the design and production processes of diaphragm seals. Utilizing simulation software and 3D printing techniques allows for quicker prototyping and testing, leading to faster delivery times and improved product designs.

Conclusion

Pressure gauge diaphragm seal manufacturers are integral to the functionality and safety of pressure measurement systems across industries. Their expertise in customization, material selection, quality assurance, and ongoing support ensures that systems remain reliable and efficient. As the industry continues to evolve, these manufacturers are at the forefront of innovation, adapting to new challenges and contributing to the optimization of processes worldwide. By understanding the vital role that these manufacturers play, industries can make informed decisions that enhance both performance and safety in their operations.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025