Dez . 06, 2024 21:15 Back to list

diaphragm seal pressure gauges supplier

Diaphragm Seal Pressure Gauges An Essential Tool for Accurate Measurements

In various industries, especially in chemical processing, oil and gas, and food and beverage, the accuracy and reliability of pressure measurements are crucial. One of the key instruments employed in these sectors is the diaphragm seal pressure gauge. This article will explore what diaphragm seal pressure gauges are, their applications, advantages, and why choosing the right supplier is vital for your operational needs.

Understanding Diaphragm Seal Pressure Gauges

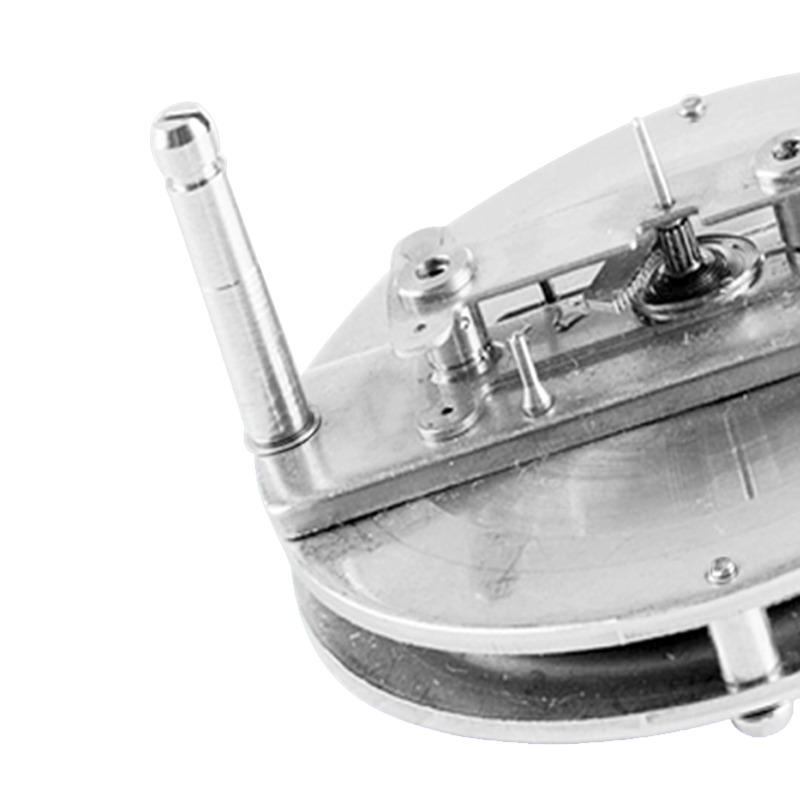

A diaphragm seal pressure gauge is a specialized type of pressure measurement device designed to withstand harsh environments. It comprises a flexible diaphragm that separates the measuring element from the process fluid. This design prevents contaminants, high temperatures, and corrosive materials from directly affecting the gauge, significantly enhancing accuracy and longevity. The diaphragm is typically made from materials like stainless steel or other alloys, selected based on the application's requirements.

Applications in Various Industries

Diaphragm seal pressure gauges are widely utilized across multiple sectors. In the chemical industry, they monitor the pressure of aggressive fluids, ensuring that processes remain within safe operating limits. In the oil and gas sector, they can be used to measure pressures in drilling and production operations where exposure to harsh conditions is common. The food and beverage industry also employs diaphragm seal gauges to ensure sanitary conditions and proper pressure control during production processes.

Moreover, these instruments are essential in pharmaceutical manufacturing, where sterile conditions must be maintained. The diaphragm seal protects the internal mechanisms of the gauge, allowing for accurate and dependable readings without contamination risks.

Advantages of Diaphragm Seal Pressure Gauges

The use of diaphragm seal pressure gauges comes with numerous advantages

1. Protection Against Process Conditions The primary benefit of a diaphragm seal is that it protects the sensing element from harsh process conditions. This is particularly crucial in environments where pressure, temperature, or fluid composition may be hazardous.

2. Enhanced Accuracy With the diaphragm acting as a barrier, the gauge can provide more accurate readings by minimizing the impact of disturbances in the process fluid.

diaphragm seal pressure gauges supplier

4. Versatility Diaphragm seal pressure gauges can handle a wide range of fluids, including viscous, corrosive, and high-temperature substances, making them suitable for various applications.

5. Customizability Suppliers often offer customization options, allowing businesses to select specific diaphragm materials, sizes, and pressure ranges that meet their individual requirements.

Choosing the Right Supplier

When selecting a diaphragm seal pressure gauge supplier, consider several important factors

1. Quality Standards Ensure that the supplier adheres to relevant industry standards and certifications. This guarantees that the gauges are of high quality and reliability.

2. Product Range A reputable supplier should offer a wide range of products to cater to different industries and applications, allowing for greater flexibility.

3. Technical Support Look for suppliers who provide excellent technical support, including guidance on product selection, installation, and maintenance.

4. Customer Reviews Investigate customer feedback and testimonials to assess the supplier's reputation and product performance.

5. Warranty and After-sales Service A solid warranty and after-sales service reflect the supplier's confidence in their product and commitment to customer satisfaction.

Conclusion

Diaphragm seal pressure gauges are essential tools for accurate and reliable pressure measurement in demanding industrial environments. Their ability to protect sensitive components from harsh conditions ensures consistent performance and longevity. Selecting the right supplier is crucial; it influences not only the quality of the gauges but also the service and support you will receive. Investing in high-quality diaphragm seal pressure gauges can lead to enhanced operational efficiency, safety, and overall productivity in your business.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025