Nov . 21, 2024 00:00 Back to list

differential pressure gauge kit

Understanding Differential Pressure Gauge Kits Essential Tools for Accurate Measurement

Differential pressure gauge kits are instrumental in various industries, including HVAC, pharmaceuticals, food processing, and chemical manufacturing. These kits are designed to measure the difference in pressure between two points in a system, providing essential data for ensuring operational efficiency and safety.

A differential pressure gauge operates by comparing two distinct pressure inputs. This functionality is crucial in applications such as monitoring filter conditions, fan operations, and system leaks. When the pressure differential exceeds a predefined threshold, it can signal potential issues within the system, prompting maintenance and preventing costly downtimes.

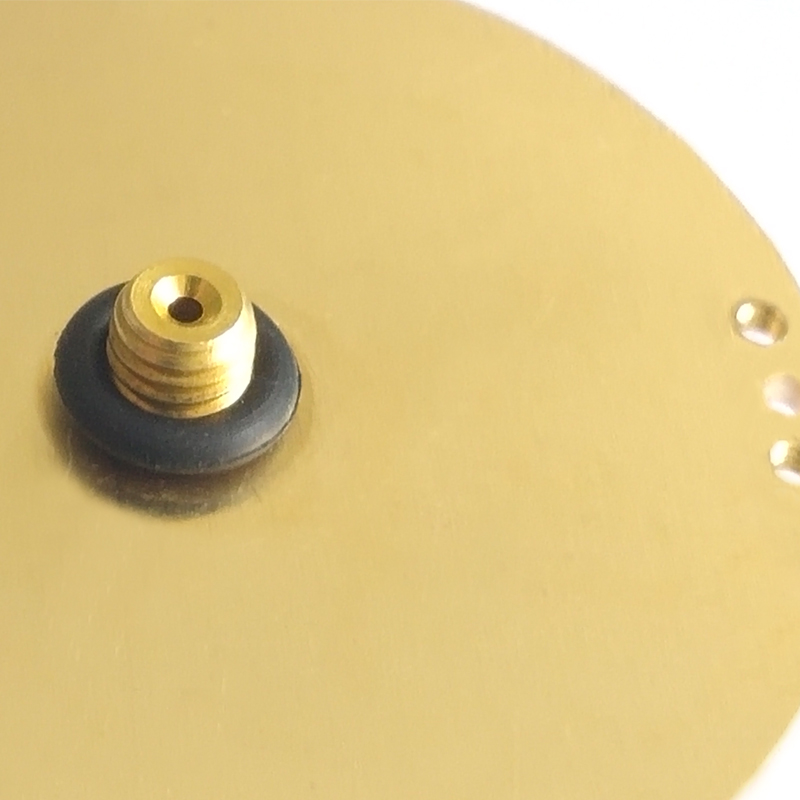

A typical differential pressure gauge kit consists of the gauge itself, tubing, pressure taps, and sometimes, installation hardware. The gauge is the heart of the kit, interpreting the pressure data and displaying it in a readable format. Various types of gauges are available, including mechanical, digital, and wireless options. Mechanical gauges use Bourdon tubes, diaphragms, or capsule elements to gauge pressure changes, while digital gauges offer more precision and are easy to read.

When selecting a differential pressure gauge kit, several factors must be considered. First, the pressure range should match the application needs. Different industries may require specific measurement ranges due to the nature of their operations. Additionally, considering the fluid type—whether gas or liquid—and its properties, such as viscosity and temperature, is crucial for accurate readings.

differential pressure gauge kit

Installation of a differential pressure gauge kit requires careful planning. Proper placement of pressure taps is essential to ensure accurate measurements. Taps should be installed away from obstructions and flow disturbances, which can lead to inaccurate readings. It’s also vital to ensure that the tubing connecting the gauge to the taps is devoid of kinks and sharp bends that could impact pressure flow.

Regular calibration of differential pressure gauges is necessary to maintain accuracy over time. Environmental conditions, such as temperature fluctuations and dust accumulation, can affect the performance of the gauges. Regular maintenance checks help in identifying any drift in measurement accuracy and ensure that the system continues to function optimally.

In industries where maintaining specific pressure differentials is critical, differential pressure gauge kits come equipped with alarm systems. These alarms provide real-time alerts to operators when pressure differences deviate from set parameters, enabling quick responses to potential issues. This feature is particularly beneficial in preventing equipment failure and ensuring safety in processes involving hazardous materials.

In conclusion, differential pressure gauge kits are vital tools for measuring pressure differentials in various applications. Their accurate readings contribute to improved operational efficiency, safety, and preventive maintenance strategies. Whether in a manufacturing plant, a laboratory, or an HVAC system, these kits play a crucial role in monitoring and controlling pressure, thereby ensuring optimal performance across various processes. Understanding their operation, proper selection, and regular maintenance is imperative for any operation relying on pressure measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025