Ago . 12, 2024 12:52 Back to list

Exploring the Applications and Benefits of Cryogenic Differential Pressure Gauges in Various Industries

Exploring Cryogenic Differential Pressure Gauges

Cryogenic differential pressure gauges are specialized instruments that play a crucial role in various applications, especially in the field of cryogenics, which deals with the production and behavior of materials at extremely low temperatures. These gauges are essential for measuring and monitoring pressure differences across systems that operate at cryogenic conditions, typically below -150 degrees Celsius (-238 degrees Fahrenheit). Understanding their functions, construction, applications, and challenges is vital for engineers and scientists working in this specialize area.

Function and Importance

The principal function of a cryogenic differential pressure gauge is to provide accurate readings of pressure differences between two points in a system. This is particularly important in cryogenic systems where maintaining specific pressure levels can be critical to the performance and safety of equipment. For instance, in a liquefied natural gas (LNG) plant, monitoring the pressure difference across various components ensures that the system operates efficiently and safely. Any deviation from the desired pressure range can indicate potential leaks or failures within the system, prompting immediate maintenance or corrective actions.

Construction and Design

Cryogenic differential pressure gauges are designed to withstand extreme temperatures and sometimes harsh environmental conditions. They typically feature a robust construction that includes materials capable of maintaining integrity at low temperatures. Common materials used in the construction of these gauges include stainless steel and specialized alloys that resist thermal contraction and other issues associated with cryogenic conditions.

The gauges operate based on a few common principles, such as the use of bellows, diaphragms, or capacitive sensors. These components react to pressure changes, converting mechanical movement into an electrical signal that can be read on an indicator or transmitted to a control system. Advances in technology have led to the development of more sophisticated electronic differential pressure gauges that offer enhanced precision, reliability, and ease of use.

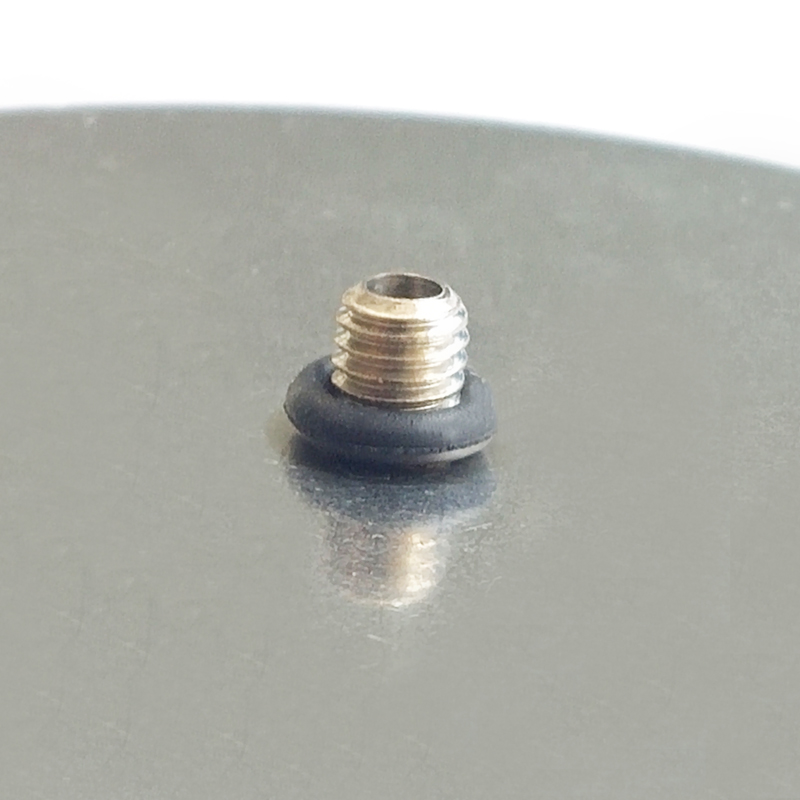

cryogenic differential pressure gauges jah

Applications

The applications of cryogenic differential pressure gauges are wide-ranging. They are extensively used in research laboratories, aerospace, medical technology, and industries like liquefied gas storage and transportation. In the field of space exploration, for example, cryogenic technologies are vital for rocket propulsion systems, where liquid hydrogen and oxygen must be stored and handled at extremely low temperatures. These gauges help monitor the pressure within fuel tanks, ensuring safe operations and optimal performance during launches.

Additionally, in the medical field, particularly in cryopreservation and organ storage, maintaining precise pressure levels is critical. Differential pressure gauges aid in monitoring the pressure of cryogenic tanks, ensuring that biological samples are preserved under optimal conditions.

Challenges

While cryogenic differential pressure gauges are essential, they also face challenges. The extreme conditions under which they operate can affect their accuracy and reliability. Factors such as thermal cycling, condensation of gases, and material fatigue can impact gauge performance. Therefore, regular calibration and maintenance are vital to ensure that these instruments provide accurate data.

In conclusion, cryogenic differential pressure gauges are integral to the safe and efficient operation of cryogenic systems. Their ability to measure and monitor pressure differences accurately under extreme conditions is crucial in a variety of applications, from industrial processes to cutting-edge research. As technology continues to advance, we can expect further improvements in the design and functionality of these essential instruments, enabling even greater precision and reliability in cryogenic applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025