Fev . 19, 2025 07:00 Back to list

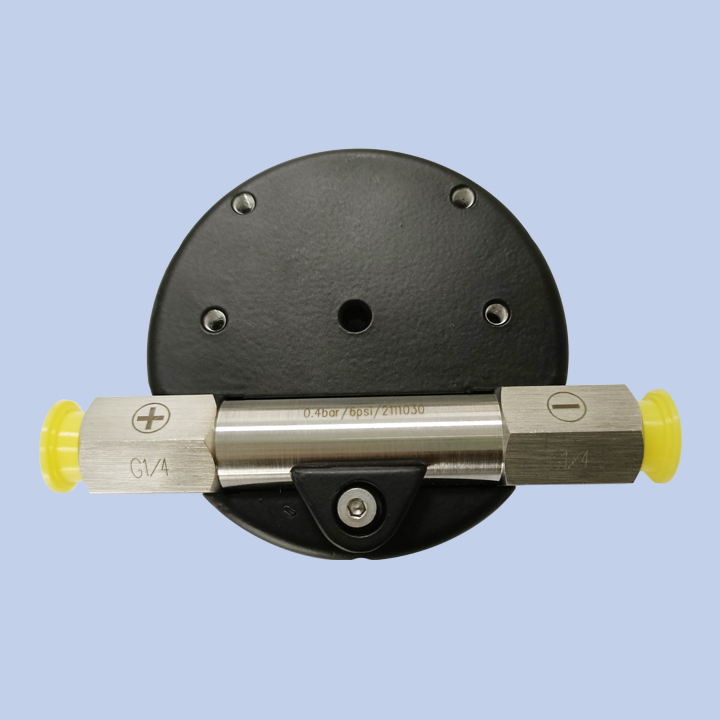

diaphragm capsule pressure gauge,

Searching for a reliable and precise instrument to measure pressure in challenging environments often leads industries to explore various options. Among these, the high-quality mass diaphragm pressure gauge stands out for its unparalleled accuracy and durability. This article delves into the features, applications, and benefits of using a top-tier mass diaphragm pressure gauge.

The expertise involved in the production of mass diaphragm pressure gauges is another testament to their quality. Manufacturers employ cutting-edge technology and rigorous testing to ensure each gauge meets the highest standards of performance. This meticulous attention to detail is reflected in the gauge's consistent output, fostering trust among users who require products that perform flawlessly under pressure. Trustworthiness is further enhanced by comprehensive customer support provided by leading manufacturers. This includes extensive documentation, technical support, and warranty services, ensuring that users have access to the necessary resources for optimal product use and maintenance. These services not only reinforce customer confidence but also underscore the manufacturer's commitment to quality and customer satisfaction. From the perspective of industry specialists, the high-quality mass diaphragm pressure gauge stands as a testament to engineering excellence. Its development is backed by years of research and innovation, aiming to address the specific challenges faced in measuring pressure within extreme conditions. This heritage of expertise assures users of a product that not only meets but often exceeds industry standards. Moreover, case studies frequently highlight the positive impacts of employing these gauges. For instance, a major oil corporation reported a 30% increase in operational efficiency after replacing their traditional gauges with high-quality mass diaphragm pressure models. Such real-world examples validate the investment in superior instrumentation, illustrating the tangible benefits these gauges bring to industrial operations. In conclusion, the high-quality mass diaphragm pressure gauge is more than just a tool; it is a key component in the orchestration of efficient and safe industrial processes. Its precision, durability, and versatility make it an indispensable asset for companies striving to optimize their operations while ensuring compliance with industry standards. Investing in these gauges ensures not only enhanced performance but also peace of mind, knowing that the measurement of pressure is in expert hands.

The expertise involved in the production of mass diaphragm pressure gauges is another testament to their quality. Manufacturers employ cutting-edge technology and rigorous testing to ensure each gauge meets the highest standards of performance. This meticulous attention to detail is reflected in the gauge's consistent output, fostering trust among users who require products that perform flawlessly under pressure. Trustworthiness is further enhanced by comprehensive customer support provided by leading manufacturers. This includes extensive documentation, technical support, and warranty services, ensuring that users have access to the necessary resources for optimal product use and maintenance. These services not only reinforce customer confidence but also underscore the manufacturer's commitment to quality and customer satisfaction. From the perspective of industry specialists, the high-quality mass diaphragm pressure gauge stands as a testament to engineering excellence. Its development is backed by years of research and innovation, aiming to address the specific challenges faced in measuring pressure within extreme conditions. This heritage of expertise assures users of a product that not only meets but often exceeds industry standards. Moreover, case studies frequently highlight the positive impacts of employing these gauges. For instance, a major oil corporation reported a 30% increase in operational efficiency after replacing their traditional gauges with high-quality mass diaphragm pressure models. Such real-world examples validate the investment in superior instrumentation, illustrating the tangible benefits these gauges bring to industrial operations. In conclusion, the high-quality mass diaphragm pressure gauge is more than just a tool; it is a key component in the orchestration of efficient and safe industrial processes. Its precision, durability, and versatility make it an indispensable asset for companies striving to optimize their operations while ensuring compliance with industry standards. Investing in these gauges ensures not only enhanced performance but also peace of mind, knowing that the measurement of pressure is in expert hands.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025