Nov . 15, 2024 06:36 Back to list

mass diaphragm pressure gauge products

Understanding Mass Diaphragm Pressure Gauge Products

Mass diaphragm pressure gauges are essential instruments commonly used in various industrial applications to measure pressure levels accurately. Their effectiveness and reliability make them a preferred choice in environments such as manufacturing, oil and gas, and chemical processing. This article delves into the fundamentals of mass diaphragm pressure gauges, their advantages, and applications.

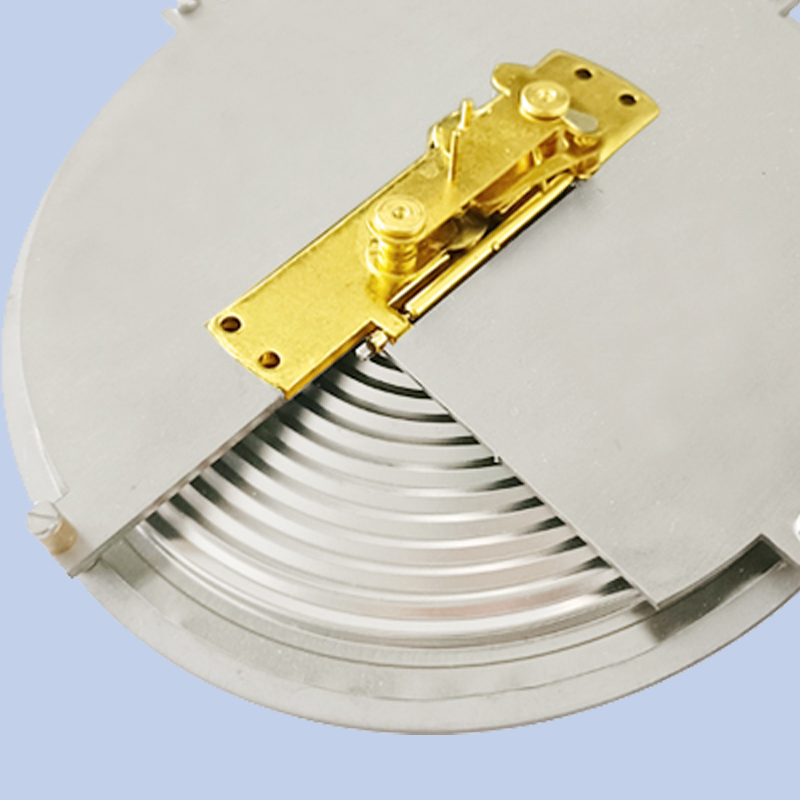

At the core of the mass diaphragm pressure gauge is a flexible diaphragm, which responds to changes in pressure. When pressure is applied, the diaphragm deforms, translating the pressure changes into mechanical movement. This movement is then amplified and displayed on a dial or digital readout, providing a clear and precise indication of pressure levels. Unlike traditional mechanical gauges, mass diaphragm designs are particularly advantageous for measuring dynamic pressures and are suited for a variety of media, including gases and liquids.

One of the primary advantages of mass diaphragm pressure gauges is their high sensitivity and accuracy. The diaphragm allows for minimal dead space, which means quicker response times and enhanced accuracy in fluctuating pressure situations. Additionally, these gauges are often crafted from durable materials, making them capable of withstanding harsh environments and corrosive substances. This durability translates into lower maintenance costs and longer service life, making them a cost-effective solution for many businesses.

mass diaphragm pressure gauge products

In terms of applications, mass diaphragm pressure gauges are utilized in various sectors. In the chemical industry, they are crucial for monitoring the pressure of hazardous materials, ensuring safety and compliance with stringent regulations. In the oil and gas sector, they help maintain optimal pressure levels in pipelines and processing equipment. Furthermore, in the food and beverage industry, these gauges assist in ensuring product quality by monitoring pressure during processing and packaging.

When selecting a mass diaphragm pressure gauge, several factors should be considered, including the range of pressures, the type of media being measured, and the environmental conditions. Gauges are available in various pressure ranges and can be equipped with different diaphragm materials depending on compatibility with the measured substance. This versatility allows industries to specify gauges that meet their particular operational demands.

In conclusion, mass diaphragm pressure gauge products are integral to numerous industrial processes, providing accurate and reliable pressure measurements. Their unique design, combined with high sensitivity and durability, makes them an excellent choice for applications across diverse sectors. As industries continue to prioritize safety and efficiency, the role of mass diaphragm pressure gauges will only become more significant, enhancing operational capabilities and ensuring quality control across the board. Whether measuring the pressure of a vast pipeline or a small-scale chemical batch, these gauges are indispensable tools for modern industry.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025