Fev . 07, 2025 01:37 Back to list

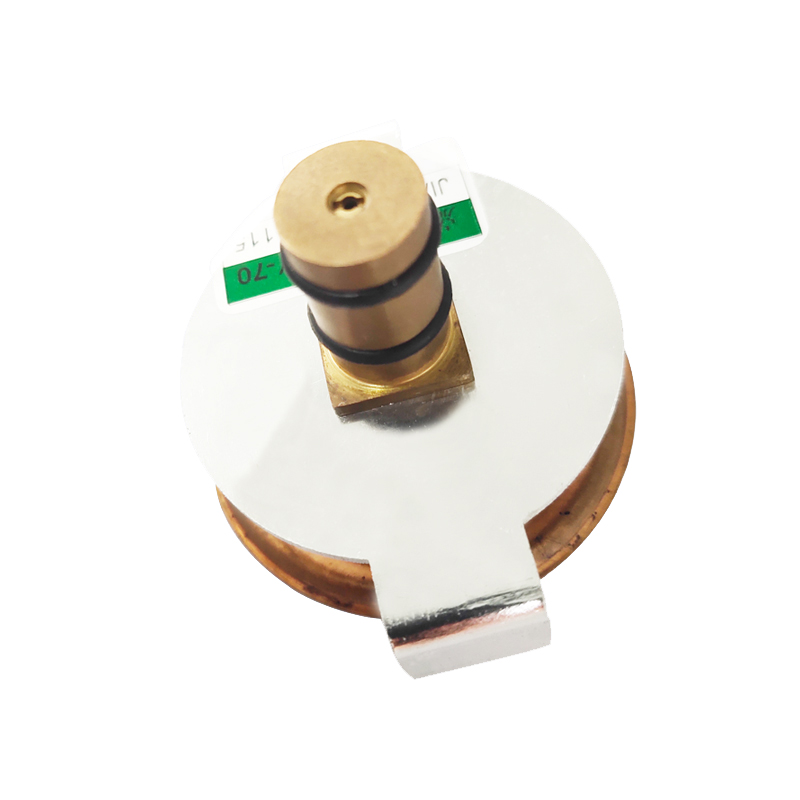

oem diaphragm contact pressure gauge

When it comes to high-precision measurement instruments, OEM diaphragm contact pressure gauges stand out as invaluable tools. These devices are specifically designed for applications where standard gauges might fail due to environmental conditions or specific material requirements. Understanding the authenticity, professionalism, authority, and trust embedded in these instruments is crucial for industries ranging from petrochemicals to pharmaceuticals.

Trustworthiness in these gauges is further reinforced by rigorous third-party testing and validation. Independent laboratories often confirm product specifications, ensuring that each gauge meets or exceeds industry requirements before reaching the market. This process underlines a commitment to transparency and reliability, establishing a bond of trust between the manufacturer and the end user. For engineers and procurement professionals looking to specify pressure measurement solutions, OEM diaphragm contact pressure gauges represent a smart choice. By integrating advanced technology with a user-centric design, these gauges offer a dependable solution for exacting applications. The flexibility of customization provided by OEM options allows users to tailor specifications to meet unique operational needs, whether in terms of pressure range, material compatibility, or output signals. Furthermore, the lifecycle costs associated with these gauges are often lower than those of conventional instruments. The robust construction and long-lasting reliability minimize the need for replacement or recalibration, reducing downtime and maintenance expenses. In an industry where time is money, such cost efficiency provides a substantial advantage. In summary, the sophistication of OEM diaphragm contact pressure gauges lies in their ability to combine empirical engineering with specialized material science. Through extensive expertise, gained both in the lab and in the field, manufacturing leaders have created pressure measurement tools that are both authoritative and dependable. Whether for ensuring safety in chemical processing or maintaining precision in pharmaceutical production, these gauges deliver unparalleled trustworthiness and performance, reaffirming their essential role across a spectrum of industries.

Trustworthiness in these gauges is further reinforced by rigorous third-party testing and validation. Independent laboratories often confirm product specifications, ensuring that each gauge meets or exceeds industry requirements before reaching the market. This process underlines a commitment to transparency and reliability, establishing a bond of trust between the manufacturer and the end user. For engineers and procurement professionals looking to specify pressure measurement solutions, OEM diaphragm contact pressure gauges represent a smart choice. By integrating advanced technology with a user-centric design, these gauges offer a dependable solution for exacting applications. The flexibility of customization provided by OEM options allows users to tailor specifications to meet unique operational needs, whether in terms of pressure range, material compatibility, or output signals. Furthermore, the lifecycle costs associated with these gauges are often lower than those of conventional instruments. The robust construction and long-lasting reliability minimize the need for replacement or recalibration, reducing downtime and maintenance expenses. In an industry where time is money, such cost efficiency provides a substantial advantage. In summary, the sophistication of OEM diaphragm contact pressure gauges lies in their ability to combine empirical engineering with specialized material science. Through extensive expertise, gained both in the lab and in the field, manufacturing leaders have created pressure measurement tools that are both authoritative and dependable. Whether for ensuring safety in chemical processing or maintaining precision in pharmaceutical production, these gauges deliver unparalleled trustworthiness and performance, reaffirming their essential role across a spectrum of industries.

Share

Latest news

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025