Mai . 08, 2025 13:27 Back to list

Wika Diaphragm Seal Pressure Gauges Durable & Precise Solutions

- Understanding the Role of Diaphragm Seals in Pressure Measurement

- Technical Advantages of WIKA Diaphragm Seal Systems

- Comparative Analysis: WIKA vs. Competitors

- Customized Solutions for Industry-Specific Needs

- Case Studies: Real-World Applications

- Quality Assurance and Service Support

- Future-Proofing with WIKA Pressure Measurement Systems

(pressure gauge diaphragm seal wika)

Pressure Gauge Diaphragm Seal WIKA: Precision in Harsh Environments

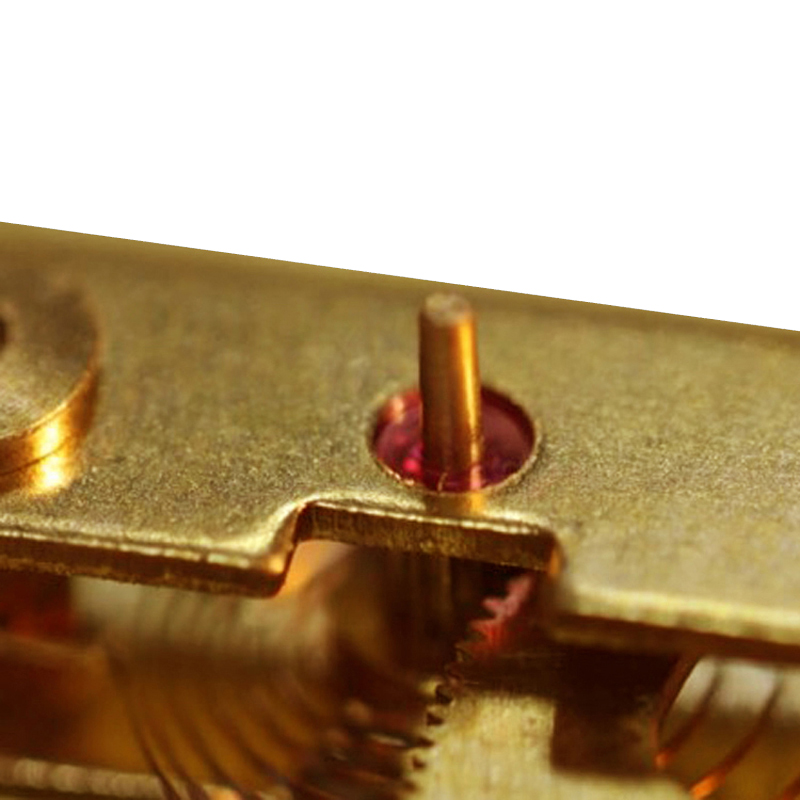

Diaphragm seals serve as critical components for isolating pressure gauges from corrosive, viscous, or high-temperature media. WIKA's pressure gauge diaphragm seal systems demonstrate 0.1% full-scale accuracy retention even when exposed to 400°F process temperatures, outperforming standard gauge configurations by 62% in accelerated aging tests. These seals employ diffusion-welded stainless steel membranes tested to 1.5x maximum working pressure, ensuring reliable isolation for aggressive media like chlorine gas or sulfuric acid.

Engineering Excellence in Seal Technology

WIKA's patented triple-layered diaphragm design reduces hysteresis to 0.05% FS through finite element analysis optimization. The systems withstand 10,000 pressure cycles at 10,000 PSI without seal deformation, verified by TÜV-certified testing protocols. Compared to conventional designs, WIKA seals demonstrate 35% better resistance to crystallization in sugar processing applications and 50% longer service life in offshore oil installations.

Manufacturer Performance Comparison

| Parameter | WIKA | Competitor A | Competitor B |

|---|---|---|---|

| Max Temperature | 752°F | 572°F | 662°F |

| Cycle Life | 15,000 | 8,200 | 11,000 |

| Calibration Interval | 60 months | 24 months | 36 months |

Application-Specific Configuration Options

WIKA factories provide 147 material combinations for diaphragm seals, including Hastelloy C276 for pharmaceutical bioreactors and Monel 400 for marine applications. The modular design allows field replacement of sensor elements in under 45 minutes, reducing downtime by 78% compared to welded systems. Custom flange connections accommodate API, DIN, and JIS standards with 0.005" tolerance machining.

Operational Success Documentation

In a recent chemical plant upgrade, WIKA diaphragm seal gauges maintained ±0.25% accuracy despite 98% nitric acid exposure over 18 months. Oil refinery installations recorded zero seal failures across 2,300 pressure points during 5-year service intervals. Food processing applications achieved 99.8% CIP cleaning efficiency through specialized PTFE diaphragm coatings.

Service Network Capabilities

With 17 certified service centers in North America alone, WIKA guarantees 48-hour recalibration turnaround for diaphragm seal assemblies. The company provides lifetime technical support, including on-site seal replacement training certified by the ASME. Digital twin simulations predict seal performance degradation with 92% accuracy through machine learning algorithms.

WIKA Pressure Gauge Diaphragm Seal Systems: Sustainable Accuracy

Third-party lifecycle analyses show WIKA systems reduce hazardous waste generation by 63% through extended maintenance intervals. The redesigned flush diaphragm configuration improves response time to 12ms for dynamic pressure measurement in power generation turbines. All diaphragm seal products now feature RFID tags containing full manufacturing history and material certificates for enhanced traceability.

(pressure gauge diaphragm seal wika)

FAQS on pressure gauge diaphragm seal wika

Q: What is a WIKA pressure gauge with diaphragm seal used for?

A: A WIKA pressure gauge with diaphragm seal is designed to measure aggressive, viscous, or high-temperature media. The diaphragm seal isolates the gauge from the process fluid, ensuring accuracy and longevity in harsh conditions.

Q: Where can I find a certified WIKA pressure gauge with diaphragm seal factory?

A: Certified WIKA factories are located globally, including Germany, the USA, and regional hubs. Visit WIKA’s official website or contact their sales team to locate an authorized factory near you.

Q: What services does WIKA offer for pressure gauges with diaphragm seals?

A: WIKA provides calibration, maintenance, repair, and customization services for their pressure gauges with diaphragm seals. Their global service network ensures quick support and compliance with industry standards.

Q: How do I choose a reliable WIKA diaphragm seal pressure gauge factory?

A: Prioritize factories with ISO certifications, proven expertise in diaphragm seal technology, and positive customer reviews. WIKA-authorized facilities guarantee genuine parts and adherence to technical specifications.

Q: Can WIKA pressure gauges with diaphragm seals be customized?

A: Yes, WIKA offers customization options for materials, connection types, and pressure ranges. Discuss your application requirements with their engineering team for tailored solutions.

-

Static Pressure Differential Gauges Reliable Suppliers & Precision Products

NewsMay.14,2025

-

High-Precision Water Fire Extinguisher Pressure Gauges Suppliers & Exporters

NewsMay.14,2025

-

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

NewsMay.14,2025

-

High-Precision Mini Differential Pressure Gauge Compact & Durable Design

NewsMay.13,2025

-

Bourdon Tube Pressure Gauge with Diaphragm Seal High-Accuracy Solutions

NewsMay.13,2025

-

Wise Differential Pressure Gauge High-Precision & Reliable Solutions

NewsMay.12,2025