Ago . 27, 2024 20:06 Back to list

Best Pressure Gauges for Medical Manufacturers | Precision and Reliability

The Best Pressure Gauge for Medical Manufacturers

In the medical field, precision and reliability are paramount. Medical manufacturers require high-quality instruments to ensure the safety and efficacy of their products, particularly when it comes to devices that monitor and regulate pressure in various applications. Among these vital tools, pressure gauges play a crucial role. Selecting the right pressure gauge is essential for maintaining accuracy and meeting the stringent regulations of the healthcare industry.

When discussing the best pressure gauge for medical manufacturers, several factors come into play. Firstly, the gauge must offer high precision and low uncertainty in its readings. Medical devices often operate within narrow pressure ranges, and any deviation can lead to catastrophic outcomes. Therefore, gauges with high accuracy ratings, generally within ±1% of the full scale, are preferred.

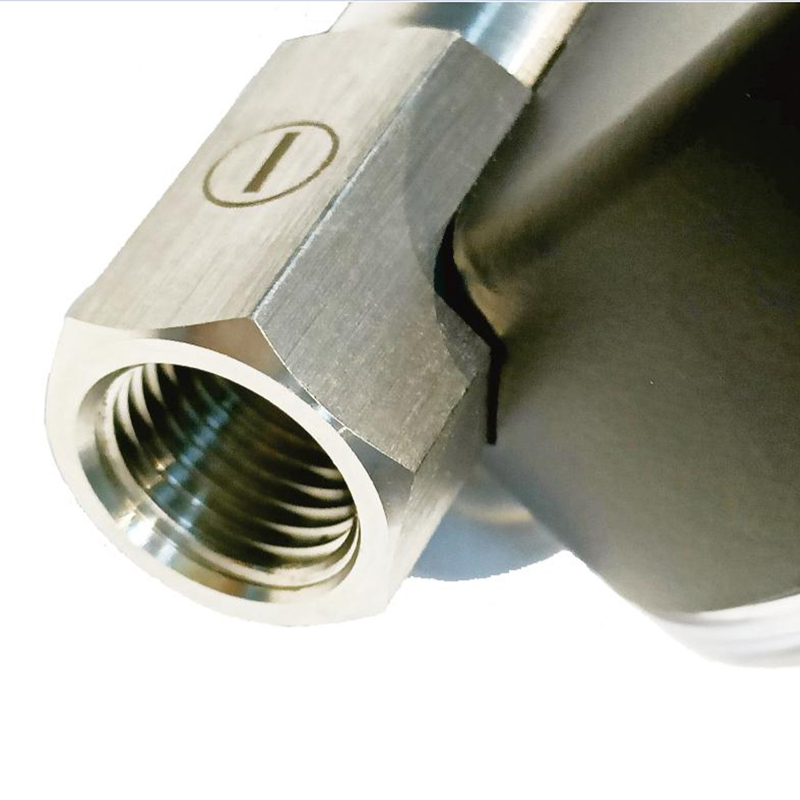

Material selection is another critical aspect. Medical environments demand materials that are biocompatible and resistant to corrosion, as well as durable enough to withstand frequent use and sterilization processes. Stainless steel and specialized polymers are often utilized for this reason. Additionally, gauges should have protective features such as overpressure limits to prevent damage under extreme conditions.

pressure gauge the best for medical manufacturers

Digital pressure gauges are increasingly popular in medical applications, offering advantages like easy readability and the ability to capture and store data for future analysis. These gauges often come equipped with features such as alarms and data logging, which enhance their functionality. For medical manufacturers, being able to monitor pressure trends over time can provide insights that improve device design and patient safety.

Moreover, regulatory compliance is crucial for medical manufacturers. Choosing a pressure gauge that meets standards set by organizations such as the FDA or ISO will ensure that the devices developed are not only effective but also safe for patient use. Manufacturers should seek gauges that come with certification and are tested for accuracy and reliability in a medical context.

Lastly, after-sales support and service are important considerations when selecting a supplier for pressure gauges. A reputable supplier should offer installation assistance, calibration services, and ongoing maintenance to ensure that the gauges remain accurate throughout their operational life.

In conclusion, the best pressure gauge for medical manufacturers is one that embodies precision, durability, regulatory compliance, and excellent support. Investing in quality gauges not only enhances the functionality of medical devices but also plays a critical role in safeguarding patient health and aligning with industry standards. By making informed choices, medical manufacturers can significantly improve the quality of care provided to patients.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025