Nov . 05, 2024 15:01 Back to list

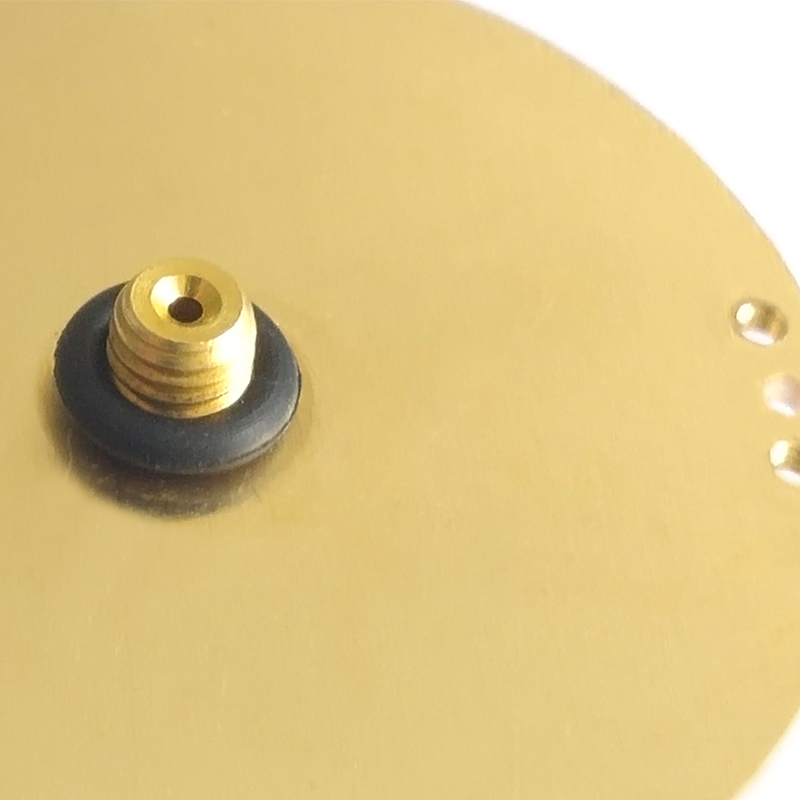

pressure gauge for fire protection service factories

Pressure Gauge for Fire Protection Service An Essential Component in Safety Management

In the realm of fire protection, ensuring the safety and efficiency of fire suppression systems is paramount. One crucial element that plays a significant role in the operation of these systems is the pressure gauge. Pressure gauges are vital instruments used to monitor the pressure in various components of fire protection systems, such as fire sprinklers, fire hydrants, and other water supply systems. This article explores the functions, types, and importance of pressure gauges specifically designed for fire protection service.

Understanding Pressure Gauges

Pressure gauges are devices that measure the pressure of gases or liquids. In the context of fire protection, they provide critical information regarding the pressure of water flowing through fire suppression systems. This data is necessary to ensure that the systems operate effectively and can successfully extinguish fires when needed. A pressure gauge's primary function is to display the pressure level to operators, enabling them to monitor system performance continuously.

Types of Pressure Gauges

There are several types of pressure gauges suitable for fire protection applications. These include

1. Bourdon Tube Gauges These are the most common type of mechanical pressure gauge. They use a coiled tube that straightens as pressure increases, moving a pointer on a dial to indicate the pressure.

2. Digital Pressure Gauges These modern gauges provide a digital display of pressure readings. They often come with additional features such as data logging, alarms for pressure deviations, and remote monitoring capabilities.

3. Diaphragm Gauges Often used in corrosive or high-temperature environments, diaphragm gauges use a flexible membrane to sense pressure changes. They are known for their durability and longevity.

4. Liquid-Filled Gauges These gauges are filled with liquid (usually glycerin) to dampen vibrations and prevent damage from shock, making them ideal for high-pressure applications.

pressure gauge for fire protection service factories

Importance of Pressure Gauges in Fire Protection

The significance of pressure gauges in fire protection cannot be overstated. Here are several reasons why these instruments are indispensable

1. System Performance Monitoring Regular monitoring of pressure levels ensures that fire protection systems are functioning correctly. Low-pressure readings could indicate a problem, such as a leak or a malfunctioning pump, which could jeopardize the system's effectiveness during a fire emergency.

2. Regulatory Compliance Many jurisdictions have strict regulations regarding fire protection systems. Regular checks and maintenance of pressure gauges can help facilities comply with these laws, avoiding potential fines and ensuring that they meet safety standards.

3. Preventative Maintenance Monitoring pressure levels can help identify issues before they escalate into significant problems. This proactive approach can save organizations time and money in repairs and replacements while enhancing overall safety.

4. Employee Safety In addition to protecting facilities, effective fire protection systems safeguard employees and visitors. By ensuring that water supply systems maintain adequate pressure, organizations can provide a safer environment for everyone present.

5. Emergency Preparedness During a fire emergency, every second counts. Pressure gauges allow the fire safety team to assess the readiness of the sprinkler system or other fire protection apparatus quickly, ensuring that they can act effectively in an emergency situation.

Conclusion

In summary, pressure gauges are essential components of fire protection services that play a critical role in maintaining the effectiveness and reliability of fire suppression systems. They help monitor pressure levels, ensure compliance with safety regulations, and ultimately protect lives and property during fire emergencies. As technology advances, the evolution of pressure gauge design continues, leading to more accurate and user-friendly instruments. Investing in quality pressure gauges is not merely a regulatory obligation; it is a fundamental commitment to safety that every organization must uphold.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025