Out . 12, 2024 21:26 Back to list

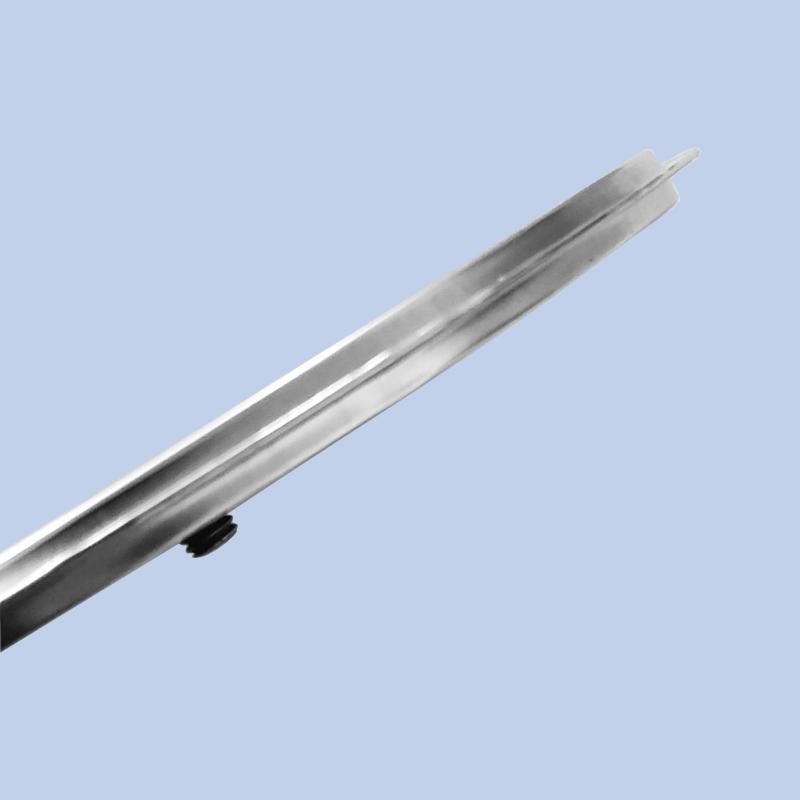

static pressure differential pressure gauge service

Understanding Static and Differential Pressure Gauge Service

In various industries, the measurement and monitoring of pressure are crucial for ensuring safe and efficient operations. Among the instruments used for these purposes, static and differential pressure gauges play pivotal roles. Understanding these gauges, their functions, and their maintenance is vital for professionals in fields like pharmaceuticals, food processing, and manufacturing.

Static Pressure Measurement

Static pressure refers to the pressure exerted by a fluid at rest. It is critical in applications where understanding the baseline pressure of a system is essential. Static pressure gauges are designed to measure this pressure without taking into account any dynamic effects caused by fluid movement. These gauges can be used in a variety of settings, including HVAC systems, hydraulic systems, and even in atmospheric pressure monitoring.

A static pressure gauge typically consists of a sensing element that responds to pressure changes in the environment. This element might be a Bourdon tube, diaphragm, or piezoelectric sensor. The choice of sensing technology depends on the specific requirements of the application, including the expected pressure range, the environment, and the degree of accuracy needed.

Differential Pressure Measurement

Differential pressure gauges, on the other hand, measure the pressure difference between two points in a system. This measurement is particularly important in applications such as filtration, where it helps ascertain the condition of a filter. By monitoring the differential pressure, operators can determine when maintenance is required or if the filter needs replacement, thus ensuring optimal performance and preventing system failures.

static pressure differential pressure gauge service

Differential pressure gauges are commonly found in various processes, including fluid dynamics, gas flow measurement, and HVAC systems. The design of these gauges allows them to handle larger pressure fluctuations, making them versatile for many industrial applications.

Service and Maintenance

The reliability of static and differential pressure gauges is heavily dependent on regular service and proper maintenance. Over time, these gauges can become clogged, corroded, or miscalibrated, leading to inaccurate readings that could compromise safety and efficiency. Routine checks should include inspecting the gauges for any signs of wear, ensuring connections are secure, and recalibrating the devices according to the manufacturer's specifications.

In addition, understanding the operational environment is critical. For instance, gauges exposed to extreme temperatures or corrosive substances may require more frequent servicing. Implementing a regular maintenance schedule can help mitigate issues before they affect the system's operation.

Conclusion

Static and differential pressure gauges are integral to various industries, providing crucial data for the effective management of systems. By understanding their functionalities and implementing a robust maintenance routine, organizations can ensure that their pressure measurement systems are reliable and accurate. This not only aids in maintaining operational efficiency but also plays a significant role in ensuring the safety of processes across different applications. Proper service of these gauges ultimately leads to enhanced performance and longevity, benefiting both the working environment and the bottom line of the organization.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025