Ago . 21, 2024 12:15 Back to list

Types of OEM Differential Pressure Gauges and Their Applications in Various Industries

Understanding OEM Differential Pressure Gauge Types

Differential pressure gauges are crucial instruments used across various industries to measure the difference in pressure between two points in a system. They play a vital role in ensuring the efficiency, safety, and reliability of processes in sectors such as HVAC, pharmaceuticals, food and beverage, and petrochemicals. This article will delve into the types of OEM (Original Equipment Manufacturer) differential pressure gauges, their applications, and the factors to consider when selecting the appropriate gauge for specific requirements.

Types of OEM Differential Pressure Gauges

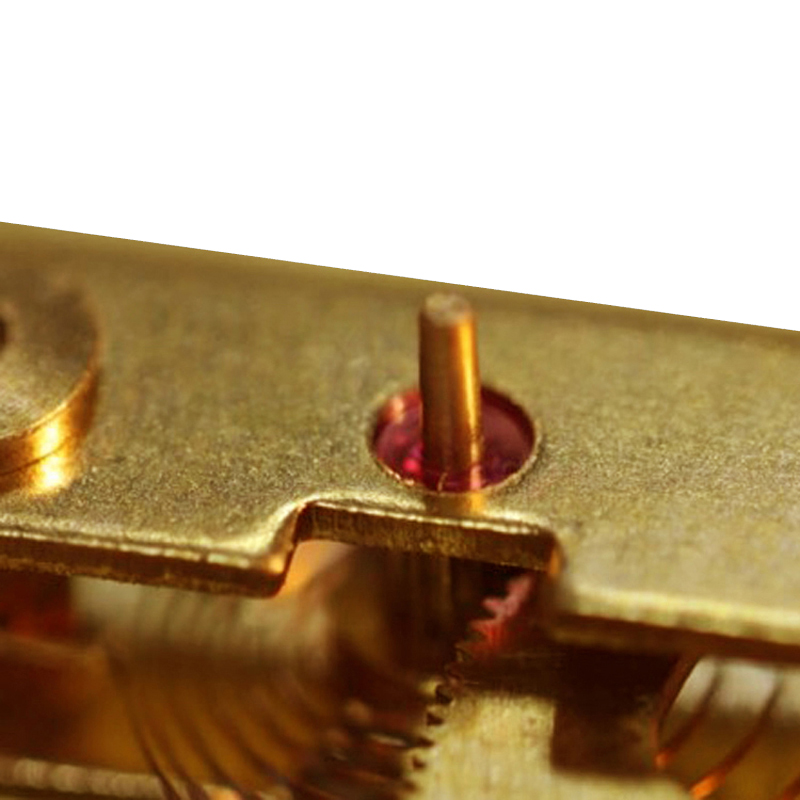

1. Mechanical Differential Pressure Gauges Mechanical differential pressure gauges are the traditional type and utilize a diaphragm or a bellow to measure pressure. As fluid pressure acts on the diaphragm, it deflects and moves a pointer across a calibrated scale. These gauges are known for their simplicity, robust construction, and high reliability, making them suitable for a wide range of applications. They are often used in water treatment plants, HVAC systems, and industrial processes where accuracy and durability are needed.

2. Electronic Differential Pressure Gauges Electronic gauges employ transducers and microprocessors to accurately measure and display differential pressure. These gauges provide real-time data, are more precise than mechanical types, and can offer features such as data logging and remote monitoring. They are particularly beneficial in applications requiring high accuracy and advanced functionalities, such as in pharmaceutical manufacturing or research laboratories.

3. Digital Differential Pressure Gauges Digital differential pressure gauges combine the accuracy of electronic gauges with digital user interfaces. They usually offer backlit displays, easy navigation through settings, and the capacity to display measurements in various units. Additionally, many digital models come equipped with alarm functions, helping operators quickly identify pressure deviations that could indicate system malfunctions.

4. Smart Differential Pressure Gauges These cutting-edge instruments are integrated with IoT (Internet of Things) capabilities, allowing them to connect to larger networks and transmit data in real-time. Smart differential pressure gauges can provide predictive maintenance alerts based on data trends, improving operational efficiency and reducing downtime. They are becoming increasingly popular in industries where operational continuity is critical, such as oil and gas or power generation.

Application Areas

Differential pressure gauges are employed in diverse applications. In HVAC systems, they monitor filter performance and airflow, ensuring optimal operation. In the pharmaceutical industry, accurate pressure readings are essential during processes like filtration and sterilization. In the petrochemical sector, they help monitor pressure drops in pipelines, ensuring that systems operate within safe parameters.

oem differential pressure gauge types

Factors to Consider When Selecting a Differential Pressure Gauge

When choosing a differential pressure gauge, several factors must be considered

1. Application Requirements Understanding the specific pressure range and environmental conditions (temperature, humidity, etc.) where the gauge will be used is crucial.

2. Accuracy Depending on the application, the required accuracy can vary. Higher accuracy might be necessary in critical applications like pharmaceuticals, while less precision might suffice for general applications.

3. Installation Environment Consider whether the gauge will be used in hazardous environments, requiring specific certifications or protection ratings.

4. Readability and Usability For many operators, a gauge that is easy to read and use can significantly affect operational efficiency. Digital displays often offer better readability than analog gauges.

5. Maintenance Needs Different types of gauges have varying maintenance requirements. Understanding the maintenance protocol can help in choosing the right gauge for long-term use.

Conclusion

OEM differential pressure gauges are invaluable tools in various industries, and understanding the differences among their types is essential for making informed decisions. By considering the specific needs of your application and the unique features of each type, you can ensure that you choose the right differential pressure gauge that enhances operational efficiency, safety, and reliability.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025