Дек . 28, 2024 22:36 Back to list

china about diaphragm pressure gauge

Understanding Diaphragm Pressure Gauges in China

In the industrial landscape of China, the diaphragm pressure gauge has emerged as a crucial instrument in various applications, ranging from manufacturing to environmental monitoring. This article explores the features, applications, and advantages of diaphragm pressure gauges while discussing their significance in China's growing economy.

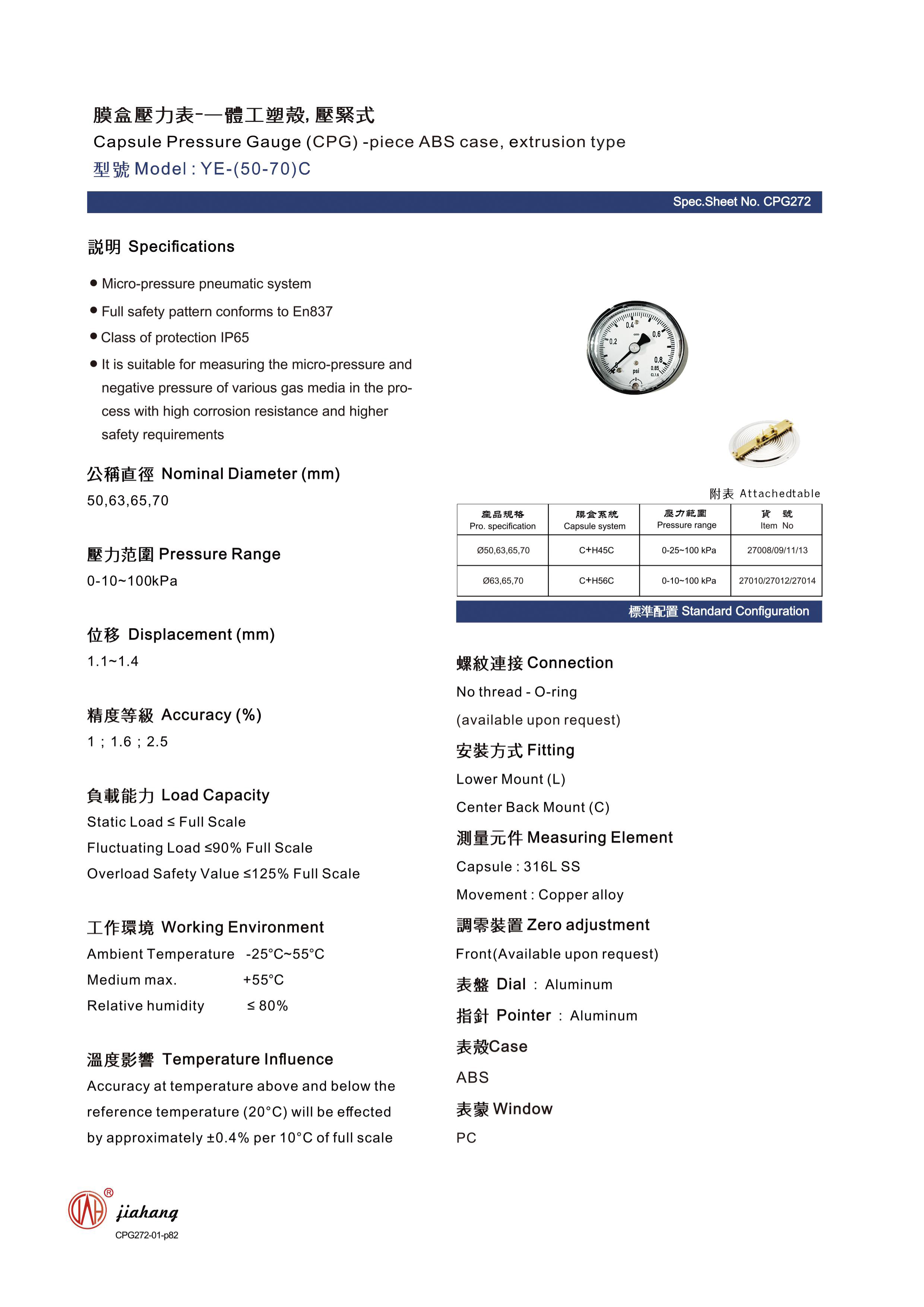

A diaphragm pressure gauge operates on a simple yet effective principle it uses a flexible diaphragm that deforms under pressure. The deformation is then translated into a readable mechanical or electronic display, providing accurate pressure readings. This design offers several advantages over traditional pressure measurement devices, making it particularly suitable for challenging environments often encountered in industrial settings.

One of the primary benefits of diaphragm pressure gauges is their ability to handle corrosive media and high-temperature conditions. Many industries in China, including petrochemicals, pharmaceuticals, and food processing, require equipment that can withstand such harsh conditions. The diaphragm, often made from corrosion-resistant materials like stainless steel, allows these gauges to perform reliably where others may fail. Consequently, their durability significantly reduces maintenance costs and downtime, ensuring operational efficiency.

Moreover, diaphragm pressure gauges boast a high level of accuracy and sensitivity, which is crucial in ensuring quality control in production processes. In China’s growing manufacturing sector, where precision is paramount, these gauges play a vital role in maintaining product standards. Industries that rely on exact pressure measurements, such as aerospace and automotive production, have integrated diaphragm gauges into their systems to enhance their quality assurance processes.

china about diaphragm pressure gauge

Another advantage lies in their compact design. Diaphragm pressure gauges can be installed in tight spaces where larger devices may not fit, making them versatile for various applications. This adaptability is particularly beneficial in manufacturing plants and laboratories, where space is often at a premium. Their lightweight design also contributes to easier handling and installation, further enhancing their usability across different operational contexts.

In terms of applications, diaphragm pressure gauges are widely utilized in the energy sector, especially in oil and gas extraction and processing. With China's status as one of the largest consumers of energy, the demand for reliable pressure measurement in this sector is critical. Diaphragm gauges help monitor pressure in pipelines and storage tanks, ensuring safety and compliance with regulatory standards. This monitoring is crucial to prevent leaks and maintain operational integrity, which ultimately protects both workers and the environment.

Furthermore, the adoption of diaphragm pressure gauges is gaining traction in the automation of industrial processes. With the advancement of smart technology and Industry 4.0, these gauges are increasingly incorporated into integrated systems that provide real-time monitoring and data analysis. Such advancements align perfectly with China's push for modernization and increased automation in its manufacturing and industrial sectors.

In summary, diaphragm pressure gauges serve as an indispensable tool in China's burgeoning industrial landscape. Their durability, accuracy, compact design, and versatility make them suitable for a variety of applications, particularly in sectors demanding high precision and safety standards. As China continues to evolve its industrial capabilities and embrace technological innovations, the importance of reliable measurement instruments like diaphragm pressure gauges will only increase, paving the way for enhanced productivity and operational excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025