Авг . 12, 2024 23:46 Back to list

China's Innovative Diaphragm Vacuum Pressure Gauges for Accurate Measurement and Reliable Performance

The Importance of Diaphragm Vacuum Pressure Gauges in Industrial Applications

Diaphragm vacuum pressure gauges play a critical role in various industrial applications, serving as essential instruments for measuring vacuum pressure with precision and reliability. These devices are particularly valuable in sectors that require high vacuums, such as semiconductor manufacturing, chemical processing, and food packaging. Understanding how diaphragm vacuum pressure gauges work and their advantages can provide insights into their significance in modern industry.

The Importance of Diaphragm Vacuum Pressure Gauges in Industrial Applications

One of the primary advantages of diaphragm vacuum pressure gauges is their ability to handle a wide range of pressures. They can provide accurate readings in both low and high vacuum conditions, which is essential for industries where specific vacuum levels must be maintained. Furthermore, diaphragm gauges are relatively rugged and can withstand harsh operating environments, including exposure to chemicals and extreme temperatures. This durability is crucial for maintaining accurate measurements and prolonging the instrument's lifespan.

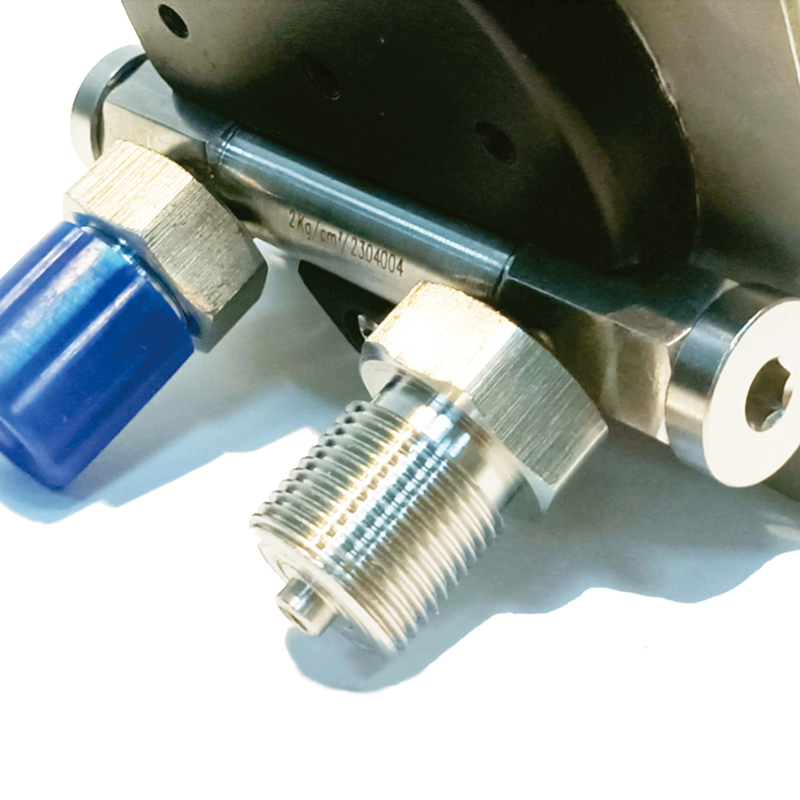

china diaphragm vacuum pressure gauge

Another noteworthy feature of diaphragm vacuum pressure gauges is their ability to offer low maintenance requirements. Unlike other types of vacuum gauges, such as those using mercury or digital sensors, diaphragm gauges do not contain hazardous materials and do not require calibrations as frequently. This not only reduces the operational costs associated with regular maintenance and recalibration but also benefits the safety of the workplace by minimizing exposure to toxic substances.

In recent years, advancements in technology have further enhanced the capabilities of diaphragm vacuum pressure gauges. Integration with digital displays, data logging, and remote monitoring functionalities have made these gauges even more user-friendly and effective in industrial settings. Operators can now easily track changes in vacuum levels, maintain optimal conditions, and respond swiftly to any fluctuations that could affect processes or product quality.

Moreover, the versatility of diaphragm vacuum pressure gauges enables their use in various applications. In the semiconductor industry, they are crucial for ensuring the integrity of vacuum chambers during the manufacturing of microchips. In the food packaging sector, these gauges help maintain the vacuum conditions necessary for extending the shelf life of products. The chemical processing industry also relies on diaphragm gauges to monitor vacuum conditions that uphold the quality and safety of chemical reactions.

In conclusion, diaphragm vacuum pressure gauges are indispensable tools in modern industrial applications. Their accuracy, durability, low maintenance requirements, and versatile capabilities make them suitable for a range of industries where vacuum pressure measurement is crucial. As technology continues to advance, these gauges are poised to further enhance operational efficiency and safety across various sectors, reinforcing their role as key instruments in the industrial landscape. Embracing such technology ultimately leads to improved product quality, operational reliability, and economic efficiency.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025