Дек . 05, 2024 15:13 Back to list

custom bourdon tube pressure gauge with diaphragm seal

Understanding Custom Bourdon Tube Pressure Gauges with Diaphragm Seal

In today's industries, precision measurement of pressure is crucial for ensuring safety and efficiency across various applications. One effective solution that has gained prominence is the custom Bourdon tube pressure gauge with a diaphragm seal. This instrument integrates the classical Bourdon tube mechanism with advanced sealing technology to provide accurate measurements in challenging environments.

The Bourdon Tube Principle

The Bourdon tube is a fundamental component of many mechanical pressure gauges. It is a curved tube that straightens when pressure is applied. The amount of straightening is proportional to the pressure inside the tube, which moves a pointer across a calibrated scale. This simple yet effective mechanism has been widely adopted for measuring pressures in gases and liquids.

However, traditional Bourdon tube gauges can face limitations in certain applications, especially when dealing with corrosive or viscous media. These conditions can compromise the integrity of the gauge and lead to inaccurate readings or equipment failure. To address these challenges, the incorporation of a diaphragm seal enhances the functionality of the Bourdon tube gauge.

Benefits of Diaphragm Seals

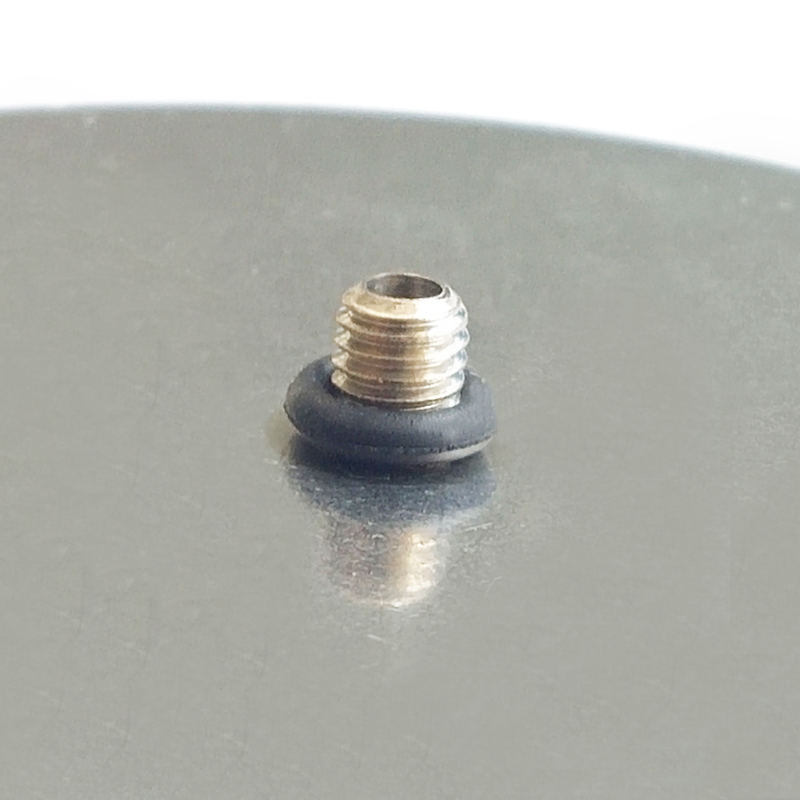

A diaphragm seal separates the Bourdon tube from the media being measured. This is particularly beneficial in two scenarios when the process fluid is corrosive or when it contains solids or particulates that could clog or damage the gauge. The diaphragm serves as a protective barrier, allowing the gauge to provide accurate readings while ensuring that the internal components are shielded from adverse conditions.

Some of the key advantages of diaphragm seals include

1. Protection Against Corrosive Media In industries like chemical processing, where media can be highly corrosive, a diaphragm seal prevents direct contact between the pressure gauge and the fluid. This prolongs the life of the gauge and reduces the risk of leaks.

custom bourdon tube pressure gauge with diaphragm seal

2. Viscous and Solid-Laden Fluids The use of diaphragm seals is critical in applications where the fluid is viscous or contains particulates. The diaphragm can help ensure that the gauge remains free from blockages, which would otherwise compromise its functionality.

3. Temperature and Pressure Compensation Custom diaphragm seals can also be designed to accommodate variations in temperature and pressure, making them suitable for a wide range of applications.

4. Customization One of the significant benefits of modern pressure gauges is the ability to customize them according to specific application needs. This customization can include the size and material of the diaphragm, as well as the gauge's scale, range, and mounting options.

Applications

Custom Bourdon tube pressure gauges with diaphragm seals find applications across numerous industries, such as

- Oil and Gas Monitoring pressure in pipelines and tanks, ensuring safety and compliance. - Pharmaceuticals Measuring pressure in sterile environments without risk of contamination. - Food and Beverage Ensuring the purity of ingredients by providing reliable pressure measurements without compromising cleanliness. - Chemical Processing Handling aggressive chemicals while maintaining accurate pressure readings.

Conclusion

In conclusion, custom Bourdon tube pressure gauges with diaphragm seals represent a critical innovation in pressure measurement technology. By combining the traditional Bourdon tube mechanism with advanced sealing solutions, these gauges deliver accurate and reliable performance even in the most challenging conditions. Industries that demand high levels of precision and safety recognize the value of these instruments, making them an essential tool for modern operational excellence. As technology continues to advance, the importance of such specialized pressure measurement devices will only grow.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025