Сен . 11, 2024 17:58 Back to list

Differential Pressure Gauge Types - Comprehensive Guide to Measurement Solutions

Understanding Differential Pressure Gauge Types and Companies

Differential pressure gauges are essential instruments widely used in various industries, including oil and gas, chemical processing, HVAC (heating, ventilation, and air conditioning), and water treatment. These gauges measure the difference in pressure between two points, helping engineers and operators monitor and maintain optimal system performance. This article explores different types of differential pressure gauges and leading companies in the market.

Types of Differential Pressure Gauges

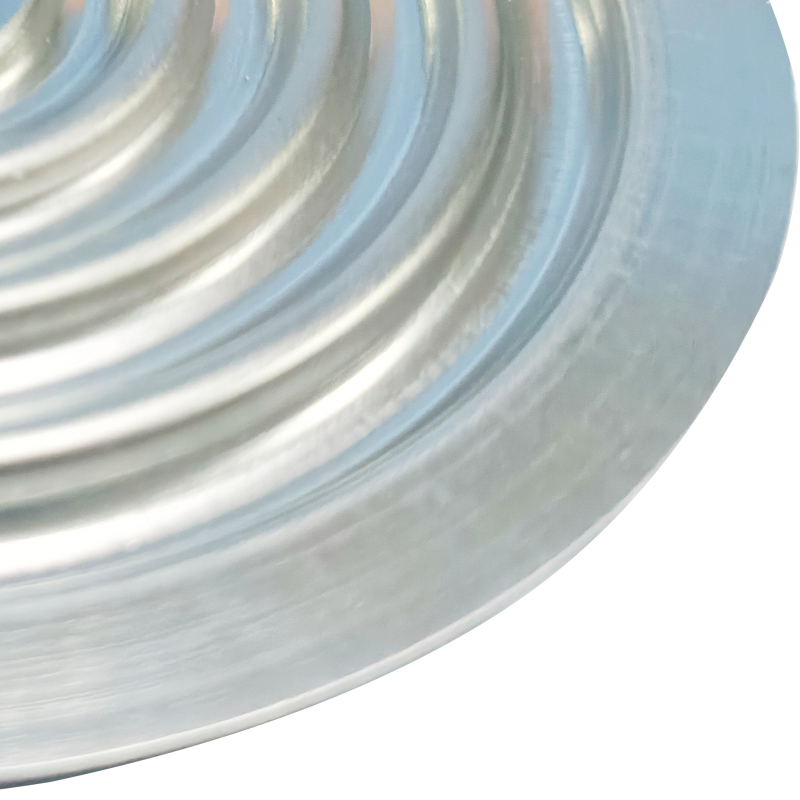

1. Mechanical Differential Pressure Gauges Mechanical gauges utilize a Bourdon tube or diaphragm to measure pressure differences. When pressure acts on the diaphragm, it deforms, causing a pointer to move along a calibrated scale. Mechanical gauges are valued for their simplicity, reliability, and no need for external power sources. They are suitable for various applications, including HVAC systems and industrial processes.

2. Electronic Differential Pressure Gauges These gauges employ sensors that convert pressure differences into electrical signals. The digital output provides accurate measurements and can be easily integrated with control systems. Electronic differential pressure gauges are characterized by their high sensitivity and ability to offer real-time data logging and remote monitoring. They are ideal for applications requiring precise control, such as clean rooms and pharmaceutical manufacturing.

3. Capacitive Differential Pressure Gauges Capacitive gauges measure pressure changes through variations in capacitance caused by the movement of a diaphragm. These gauges are highly accurate and extremely sensitive, making them excellent for low-pressure applications, such as in research laboratories or semiconductor manufacturing. They are often preferred in situations where minute pressure changes need to be monitored closely.

4. Differential Pressure Transmitters Unlike traditional gauges, transmitters convert differential pressure measurement into a standardized output signal (like 4-20 mA or digital signals). This feature allows for easy integration into advanced automation systems and provides long-distance signal transmission. Differential pressure transmitters are commonly used in process industries and critical applications where continuous monitoring is vital.

Leading Companies in the Differential Pressure Gauge Market

differential pressure gauge types companies

Several reputable companies specialize in the design and manufacture of differential pressure gauges. Prominent players include

- Emerson A global leader in automation and control technologies, Emerson offers various differential pressure gauges and transmitters that emphasize high accuracy and reliability.

- Honeywell Known for its broad spectrum of industrial solutions, Honeywell manufactures advanced differential pressure gauges suited for diverse applications.

- Siemens With a strong focus on innovation, Siemens provides cutting-edge differential pressure measurement solutions that integrate seamlessly into their industrial automation systems.

- Endress+Hauser This company is renowned for its high-quality measuring instrumentation, including differential pressure instruments that cater to a wide range of industries.

- Ashcroft A trusted name in pressure measurement, Ashcroft produces a variety of differential pressure gauges, known for their durability and performance in harsh environments.

Conclusion

Differential pressure gauges play a pivotal role in maintaining operational efficiency across multiple industries. Their various types, whether mechanical, electronic, capacitive, or transmitters, cater to diverse application needs. Leading companies in this field continue to innovate, ensuring that industries have access to reliable and accurate pressure measurement solutions. Understanding these instruments and their manufacturers is crucial for engineers and operators aiming to optimize their systems effectively.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025