Дек . 26, 2024 09:23 Back to list

Manufacturer of Differential Pressure Gauge Assembly for Various Applications and Industries

The Importance of Differential Pressure Gauge Assembly in Industry

Differential pressure gauges play a crucial role in many industrial applications, offering essential measurements that ensure processes run smoothly and efficiently. These devices are critical for monitoring the pressure difference between two points in a system, providing valuable data that can inform maintenance, operations, and safety protocols. Manufacturers of differential pressure gauge assemblies have developed increasingly sophisticated products that promise enhanced accuracy, durability, and ease of use.

Understanding Differential Pressure

To grasp the significance of differential pressure gauges, it's important to understand what they measure. Differential pressure refers to the difference in pressure between two points in a system. This measurement is fundamental in a variety of sectors, including oil and gas, water treatment, HVAC, and pharmaceuticals, among others. By knowing the differential pressure, operators can determine flow rates, filter conditions, and system performance.

Components of Differential Pressure Gauge Assemblies

A typical differential pressure gauge assembly consists of several key components

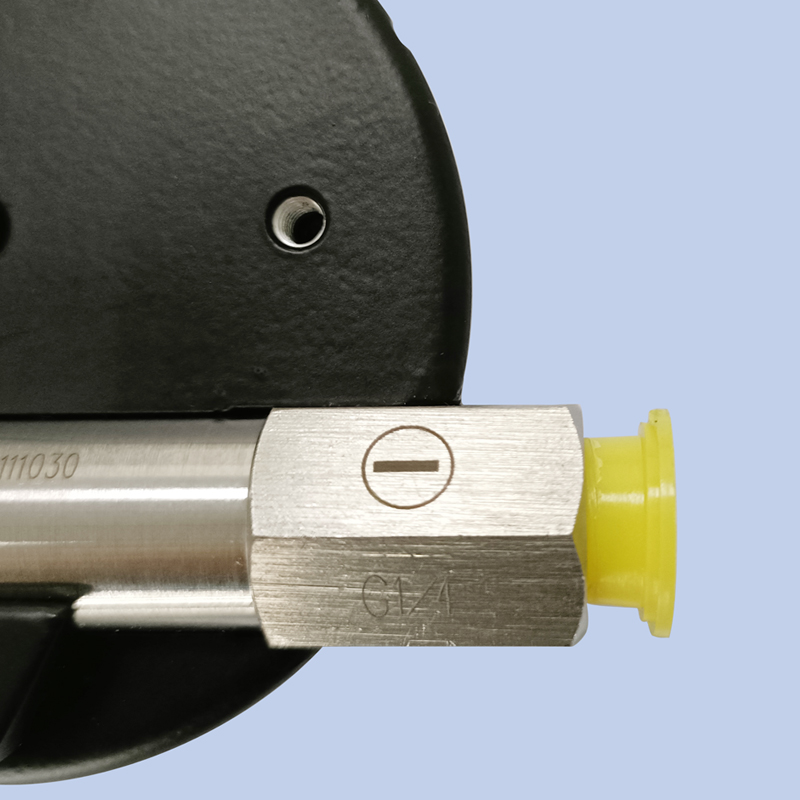

1. Sensing Element This is the heart of the gauge, where the pressure measurement occurs. Common types of sensing elements include diaphragms and engaged Bourdon tubes, which respond to pressure changes and provide a readable output.

2. Dial Indicator The dial is the visual component where operators can see the pressure reading. It often features clear markings for quick reference and some models might include digital displays for enhanced visibility.

3. Connection Ports These are the points where the gauge connects to the system, which may include tubing or flanges. Proper connection is essential for accurate readings.

4. Isolation Valves Often included in the assembly, these valves allow for maintenance and calibration of the gauge without needing to shut down the entire system.

5. Housing A robust housing protects sensitive components from environmental factors such as dust, moisture, and extreme temperatures.

Advantages of Using Differential Pressure Gauges

1. Enhanced Process Control By continuously monitoring pressure differences, operators can optimize processes, adjust flow rates, and ensure systems operate within designated parameters. This capability supports increased efficiency and productivity.

differential pressure gauge assembly manufacturer

2. Predictive Maintenance Differential pressure measurements can signal when filters or other components need maintenance or replacement. This proactive approach minimizes downtime and avoids costly unplanned outages.

3. Safety and Compliance Accurate pressure measurements are crucial for maintaining safe operating conditions within industrial environments. Differential pressure gauges help ensure compliance with industry regulations, safeguarding both personnel and equipment.

4. Versatile Applications These gauges are employed in a myriad of applications, from monitoring air filters in HVAC systems to assessing pressure drop across heat exchangers in chemical processing. Their versatility makes them an essential tool across various industries.

Choosing the Right Manufacturer

With the critical role differential pressure gauges play, it's important to select a reputable manufacturer. Leading manufacturers focus on quality and precision engineering to produce reliable products. They often provide extensive testing and certification processes to ensure their gauges meet industry standards.

When evaluating manufacturers, consider factors such as

- Experience and Expertise Look for companies with a proven track record in producing differential pressure instruments.

- Custom Solutions Some manufacturers offer tailored solutions to meet specific operational requirements, allowing for greater flexibility in system design.

- Support and Service After-sales support is crucial. Reliable manufacturers provide assistance during installation, calibration, and troubleshooting of their products.

- Innovation The best manufacturers are at the forefront of technology, integrating the latest advancements into their designs to improve performance and usability.

Conclusion

Differential pressure gauge assemblies are indispensable in modern industry, providing critical data that supports operational efficiency and safety. As technology advances, the effectiveness of these gauges continues to improve, driven by dedicated manufacturers committed to quality and innovation. Whether in process control, maintenance, or ensuring safety, understanding and utilizing differential pressure measurements is vital for any industrial operation. As businesses strive for greater efficiency and reliability, the role of differential pressure gauges will undoubtedly become even more significant in the future.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025