Сен . 05, 2024 10:54 Back to list

jah capsuhelic differential pressure gauge

Understanding Jah Capsule Helical Differential Pressure Gauge

The Jah Capsule Helical Differential Pressure Gauge, a remarkable instrument in the realm of pressure measurement, plays a critical role in various industries by providing accurate and reliable assessments of differential pressure. Understanding its design, functionality, and applications is essential for professionals across domains that require precise pressure monitoring.

Design and Mechanics

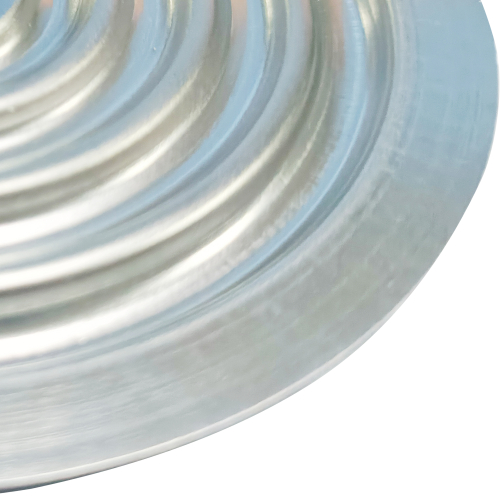

The Jah Capsule Helical Differential Pressure Gauge is constructed using a helical spring mechanism. This innovative design comprises a series of helical capsules that respond to pressure differentials. When pressure is applied to one side of the capsule, the helical structure undergoes a linear displacement, which is translated into a readable measurement on the gauge. The helical configuration not only enhances sensitivity but also ensures durability, making it a reliable choice for both laboratory and field applications.

Working Principle

The working principle behind the Jah Capsule Helical Differential Pressure Gauge is built around the concept of measuring the difference in pressure between two points. When fluid flows through a system, variations in pressure can occur due to changes in elevation, flow rate, or system resistance. The gauge can detect these nuances by comparing the pressure at two separate points. As the differential pressure increases, the helical capsules expand or contract accordingly, resulting in a movement that can be easily read on the calibrated scale of the gauge.

Calibration and Accuracy

jah capsuhelic differential pressure gauge

One of the critical aspects of ensuring the efficacy of any pressure gauge is calibration. The Jah Capsule Helical Differential Pressure Gauge is designed for high precision and can be calibrated to meet specific industrial standards. Regular calibration is essential to maintain accuracy, particularly in critical applications such as pharmaceuticals, food processing, and oil and gas industries, where even the slightest deviation can lead to significant consequences. Its robust construction allows for consistent performance, making it a favored choice among professionals.

Applications

The applications of the Jah Capsule Helical Differential Pressure Gauge are vast and varied. In the oil and gas sector, it is instrumental in monitoring wellhead pressures and ensuring safe operations in drilling and extraction activities. In the pharmaceutical industry, this gauge is used to maintain controlled environments by monitoring differential pressures in sterile processing areas.

Additionally, the gauge is crucial in HVAC systems, where it helps maintain air quality and efficiency by monitoring the performance of filters and ductwork. Its ability to gauge low and high-pressure differentials makes it versatile for both industrial and commercial applications.

Conclusion

In conclusion, the Jah Capsule Helical Differential Pressure Gauge stands out as a vital tool in modern pressure measurement. Its unique design, working principle, and versatility make it indispensable across various sectors. By providing accurate readings and facilitating better control of processes, this gauge not only enhances operational efficiency but also contributes to safety and regulatory compliance. For professionals dealing with pressure systems, investing in a Jah Capsule Helical Differential Pressure Gauge can significantly improve the reliability and integrity of their operations. Such instruments are not just gauges; they are key components that underpin the success of complex systems in various industries.

-

Top Diaphragm Seal Pressure Gauge Suppliers Precision & Durability

NewsMay.29,2025

-

Ashcroft Diaphragm Pressure Gauges High Accuracy & Durable Design

NewsMay.29,2025

-

WIKA Diaphragm Seal Pressure Gauges Corrosion-Resistant & Durable

NewsMay.29,2025

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025