Июл . 27, 2024 22:23 Back to list

Reliable Differential Pressure Gauge Solutions for High Accuracy Measurement Needs in Various Industries

High Accuracy Differential Pressure Gauge Service Ensuring Precision in Measurement

In numerous industrial applications, accurate measurements of pressure differences are crucial for maintaining optimal processes and ensuring safety standards. High accuracy differential pressure gauges play a significant role in monitoring and controlling various environmental parameters in sectors such as oil and gas, pharmaceuticals, food and beverage, and HVAC systems. This article explores the importance of these gauges, their operational principles, and the services associated with maintaining high precision.

Understanding Differential Pressure Gauges

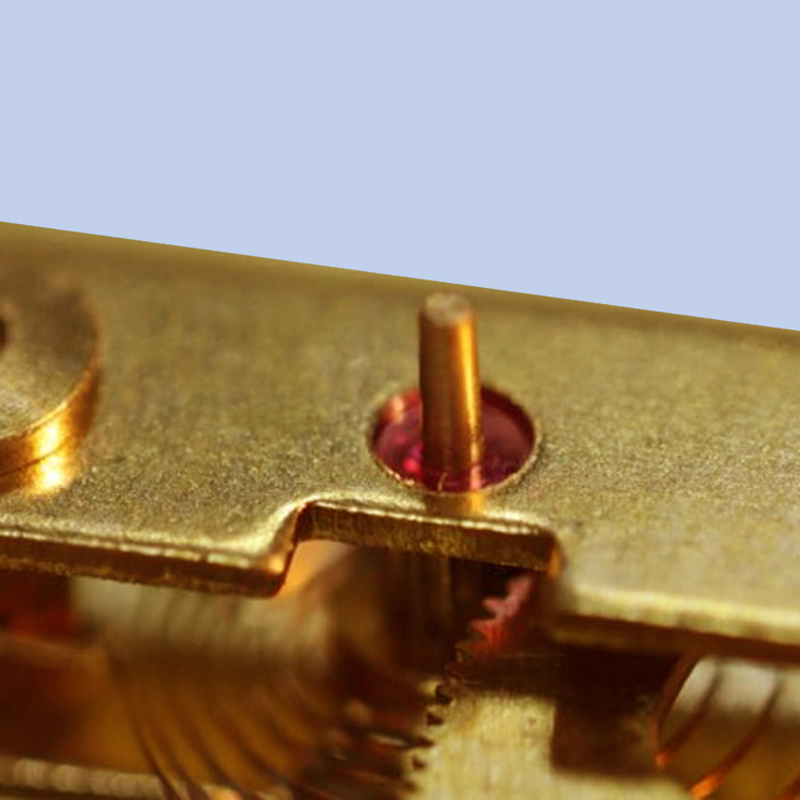

A differential pressure gauge measures the difference in pressure between two points in a system. This measurement can indicate flow rates, filter condition, and level of fluids in tanks, among other critical data. The accuracy of these gauges is paramount; even minor errors can lead to inefficiencies, safety hazards, and increased operational costs. High accuracy gauges are designed with specialized materials and precision engineering to minimize errors and ensure reliable readings under varying conditions.

Importance of High Accuracy

High accuracy differential pressure gauges are essential in many applications. For example, in the pharmaceutical industry, maintaining sterile conditions is critical; any deviation in pressure can lead to contamination. Similarly, in the oil and gas industry, exact measurements are vital for monitoring pipeline integrity, ensuring safe operations, and preventing leaks that can result in environmental disasters. In HVAC systems, accurate pressure readings help maintain optimal indoor air quality and energy efficiency.

Calibration and Maintenance Services

To ensure that high accuracy differential pressure gauges provide reliable performance, regular calibration and maintenance are essential. Calibration involves comparing the gauge against a known standard to verify its accuracy. This process should be conducted periodically, as environmental changes and wear over time can affect performance.

Professional servicing of these gauges includes

1. Inspection Regular inspections help identify any physical damage or wear that could affect readings. This aspect of service is critical to avoid unexpected failures.

high accuracy differential pressure gauge service

2. Calibration Utilizing precision calibration equipment, technicians adjust the gauge as needed to ensure it reads accurately against industry standards.

3. Cleaning In many applications, contaminants can gather in the gauge, affecting its operation. Professional cleaning can restore proper functioning.

4. Replacement of Components Over time, certain components may wear out, necessitating replacement to maintain accuracy and reliability.

5. Documentation Keeping accurate records of calibration and maintenance provides traceability and can be crucial for compliance with industry regulations.

Choosing the Right Service Provider

When selecting a service provider for high accuracy differential pressure gauges, it is essential to consider several factors. A qualified provider should have experience in the specific industry relevant to the application of the gauges. They should also possess the necessary certifications and use certified calibration standards.

Additionally, the provider should offer a comprehensive service plan that includes routine checks, emergency repairs, and replacement parts. Choosing a service provider with a solid track record of reliability and customer satisfaction is vital for ensuring the long-term accuracy of differential pressure measurements.

Conclusion

High accuracy differential pressure gauges are indispensable in maintaining operational efficiency and safety across a range of industries. Regular calibration and maintenance services are essential to ensure these instruments provide precise measurements. By engaging with qualified service providers, businesses can protect their processes and guarantee the accuracy of their measurements, ultimately leading to enhanced performance and reduced risks. As technology continues to evolve, the significance of accurate pressure measurement remains paramount in driving industrial innovation and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025