Haz . 18, 2024 03:23 Back to list

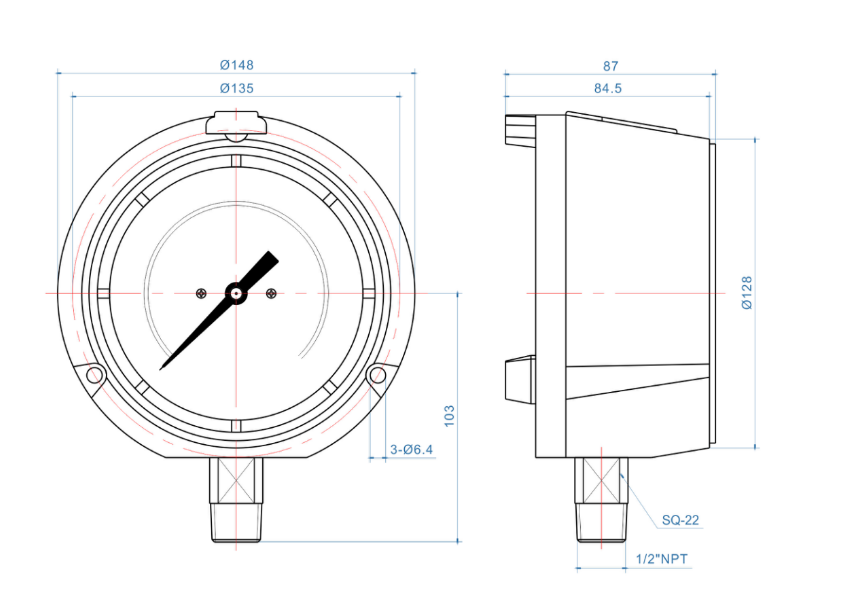

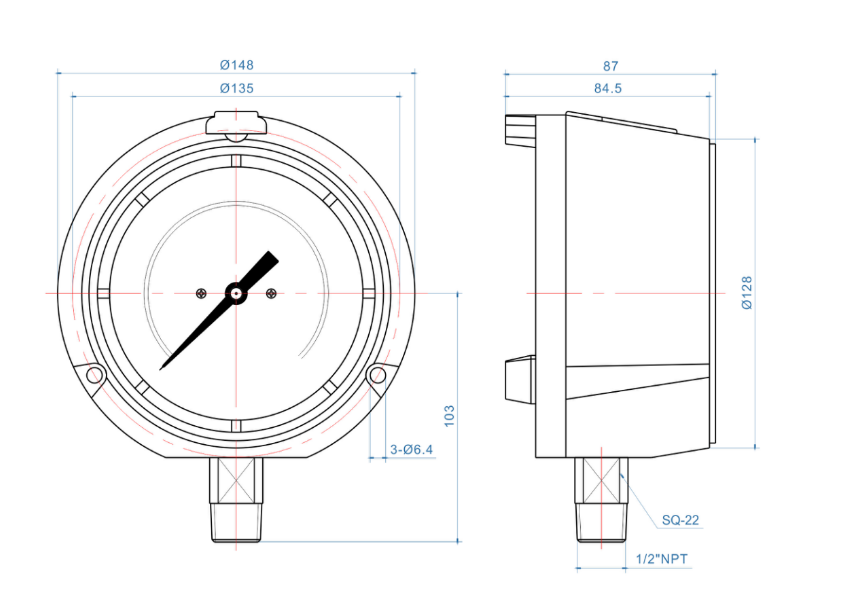

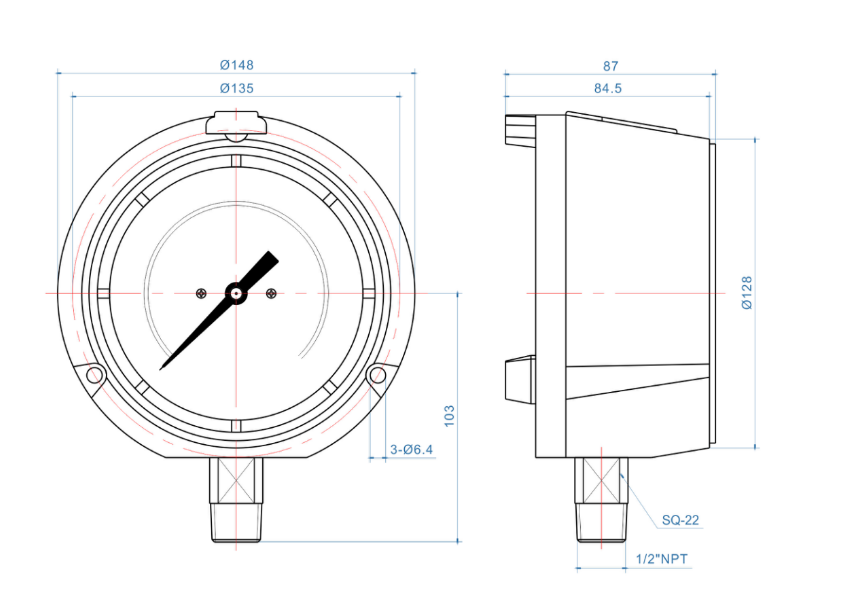

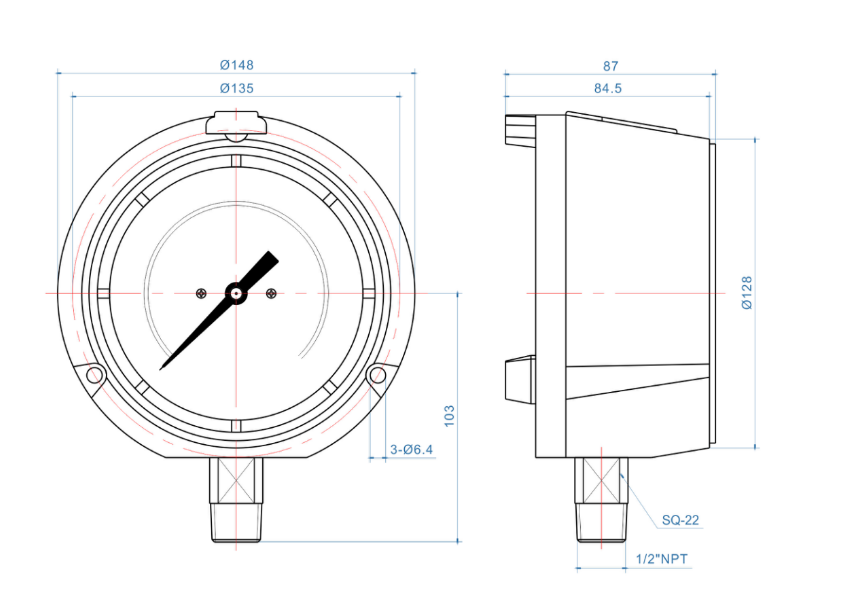

Diaphragm-type pressure gauge used for specific service.

Understanding the Function and Importance of Diaphragm Type Pressure Gauges in Industrial Services

A diaphragm type pressure gauge is an essential instrument employed in various industrial applications for precise measurement of pressure. This specialized gauge utilizes a flexible diaphragm as its sensing element, making it highly efficient and accurate in specific service conditions.

The diaphragm, typically made from stainless steel or other corrosion-resistant materials, separates the process fluid from the gauge mechanism. This design feature ensures that the gauge is protected from the effects of aggressive or corrosive media, extending its lifespan and maintaining accuracy over time. It also allows the gauge to function effectively in high-purity applications where contamination must be prevented.

Diaphragm type pressure gauges come in two main configurations sealed and unsealed. In a sealed diaphragm gauge, the space between the diaphragm and the pressure indicator is filled with a fill fluid, which transmits the pressure without allowing the process fluid to directly contact the gauge. This is particularly useful in high-temperature or high-pressure environments. Unsealed diaphragm gauges, on the other hand, directly transfer the pressure through the diaphragm, making them ideal for low-pressure measurements.

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment diaphragm type pressure gauge service. They are often used in services where the measured medium may cause damage to standard pressure gauges, such as slurries, viscous fluids, or gases with particulate matter. The diaphragm's rigidity and sensitivity make it adept at detecting minute pressure changes, thus ensuring process control and safety.

The serviceability of a diaphragm type pressure gauge is another key aspect. Regular maintenance and calibration are necessary to maintain the precision and reliability of the instrument. However, due to the diaphragm's isolation properties, these tasks can be performed without interrupting the process flow, minimizing downtime.

In conclusion, the diaphragm type pressure gauge is a critical tool in industrial services, providing reliable pressure measurement in challenging environments. Its unique design, resistance to harsh media, and versatility make it a go-to solution for engineers and technicians dealing with diverse pressure monitoring needs. Despite requiring proper care and maintenance, the benefits of using a diaphragm type pressure gauge far outweigh the costs, ensuring safe and efficient operation in many industrial processes.

diaphragm type pressure gauge service. They are often used in services where the measured medium may cause damage to standard pressure gauges, such as slurries, viscous fluids, or gases with particulate matter. The diaphragm's rigidity and sensitivity make it adept at detecting minute pressure changes, thus ensuring process control and safety.

The serviceability of a diaphragm type pressure gauge is another key aspect. Regular maintenance and calibration are necessary to maintain the precision and reliability of the instrument. However, due to the diaphragm's isolation properties, these tasks can be performed without interrupting the process flow, minimizing downtime.

In conclusion, the diaphragm type pressure gauge is a critical tool in industrial services, providing reliable pressure measurement in challenging environments. Its unique design, resistance to harsh media, and versatility make it a go-to solution for engineers and technicians dealing with diverse pressure monitoring needs. Despite requiring proper care and maintenance, the benefits of using a diaphragm type pressure gauge far outweigh the costs, ensuring safe and efficient operation in many industrial processes.

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment

These gauges find their niche in industries like chemical processing, petrochemicals, pharmaceuticals, food and beverage, and water treatment diaphragm type pressure gauge service. They are often used in services where the measured medium may cause damage to standard pressure gauges, such as slurries, viscous fluids, or gases with particulate matter. The diaphragm's rigidity and sensitivity make it adept at detecting minute pressure changes, thus ensuring process control and safety.

The serviceability of a diaphragm type pressure gauge is another key aspect. Regular maintenance and calibration are necessary to maintain the precision and reliability of the instrument. However, due to the diaphragm's isolation properties, these tasks can be performed without interrupting the process flow, minimizing downtime.

In conclusion, the diaphragm type pressure gauge is a critical tool in industrial services, providing reliable pressure measurement in challenging environments. Its unique design, resistance to harsh media, and versatility make it a go-to solution for engineers and technicians dealing with diverse pressure monitoring needs. Despite requiring proper care and maintenance, the benefits of using a diaphragm type pressure gauge far outweigh the costs, ensuring safe and efficient operation in many industrial processes.

diaphragm type pressure gauge service. They are often used in services where the measured medium may cause damage to standard pressure gauges, such as slurries, viscous fluids, or gases with particulate matter. The diaphragm's rigidity and sensitivity make it adept at detecting minute pressure changes, thus ensuring process control and safety.

The serviceability of a diaphragm type pressure gauge is another key aspect. Regular maintenance and calibration are necessary to maintain the precision and reliability of the instrument. However, due to the diaphragm's isolation properties, these tasks can be performed without interrupting the process flow, minimizing downtime.

In conclusion, the diaphragm type pressure gauge is a critical tool in industrial services, providing reliable pressure measurement in challenging environments. Its unique design, resistance to harsh media, and versatility make it a go-to solution for engineers and technicians dealing with diverse pressure monitoring needs. Despite requiring proper care and maintenance, the benefits of using a diaphragm type pressure gauge far outweigh the costs, ensuring safe and efficient operation in many industrial processes. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025