Kas . 18, 2024 21:18 Back to list

flush diaphragm pressure gauge exporters

The Role of Flush Diaphragm Pressure Gauges in Various Industries

Pressure measurement is a fundamental aspect in many industrial processes, and the accuracy of this measurement can directly impact the efficiency, safety, and overall effectiveness of operations. Among the different types of pressure gauges available, flush diaphragm pressure gauges have gained significant prominence due to their unique design and functionality. As industry demands evolve, the role of flush diaphragm pressure gauge exporters becomes increasingly vital.

Understanding Flush Diaphragm Pressure Gauges

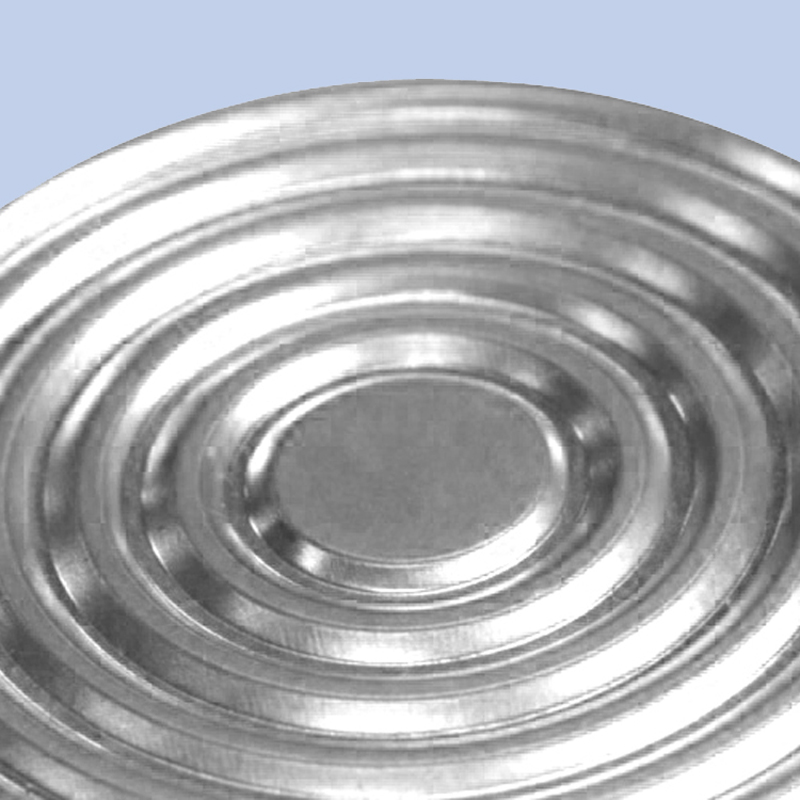

Flush diaphragm pressure gauges are specialized devices that consist of a flexible diaphragm separating the process medium from the mechanical measurement elements. This design allows for accurate pressure measurement even in environments where traditional gauges may struggle. The flush diaphragm configuration is particularly advantageous in applications involving viscous, corrosive, or hygienic fluids. The flush mount feature minimizes dead space, reducing the risk of clogging and ensuring quicker response times to pressure changes.

Key Advantages

1. Sanitary Applications One of the primary advantages of flush diaphragm pressure gauges is their suitability for sanitary applications, such as in the food and pharmaceutical industries. Their design facilitates easy cleaning and sanitation, making them ideal for environments that require stringent hygiene standards.

2. Resistance to Corrosion and Contamination Many flush diaphragm gauges are constructed using high-quality materials such as stainless steel, which can withstand corrosive environments. This resistance helps extend the lifespan of the gauges, reducing replacement costs and downtime.

3. Accurate Measurement in Harsh Conditions Flush diaphragm gauges can accurately measure pressure in conditions where traditional gauges may fail. For instance, in processes involving slurries or viscous materials, the flush design can prevent the buildup of materials that would obstruct measurement.

4. Versatile Applications Because of their robust design and adaptability, flush diaphragm pressure gauges find applications across a variety of industries, including oil and gas, chemicals, water treatment, and HVAC systems. This versatility makes them a preferred choice for many engineers and process managers.

flush diaphragm pressure gauge exporters

Market Dynamics

As industries increasingly recognize the benefits of flush diaphragm pressure gauges, the demand for high-quality products has grown. This surge in demand has led to the emergence of numerous exporters specializing in this niche market. These exporters play a crucial role in ensuring that businesses have access to reliable and efficient pressure measurement solutions. They are tasked with not only manufacturing these gauges but also adhering to international quality standards and regulations.

Global Export Trends

The global market for flush diaphragm pressure gauges is influenced by various factors, including technological advancements, regulatory requirements, and changes in consumer preferences. Exporters must stay updated with these trends to remain competitive. For instance, the rise of Industry 4.0 and digitalization in manufacturing processes might lead to increased demand for smart gauges equipped with IoT capabilities.

Moreover, trade agreements and tariffs can also impact the flow of goods. Exporters need to navigate these complexities effectively to optimize their supply chains and maintain cost competitiveness.

Conclusion

Flush diaphragm pressure gauges offer significant advantages in terms of accuracy, reliability, and versatility across multiple industries. As the demand for these specialized instruments continues to grow, the role of flush diaphragm pressure gauge exporters becomes increasingly important. They not only provide essential products but also contribute to the advancement of measurement technology in industries that rely on precise and trustworthy pressure readings.

For businesses looking to invest in high-quality measuring instruments, partnering with reputable exporters can ensure access to innovative and compliant solutions that meet the evolving needs of their operational environments. As industries continue to innovate and aim for greater efficiency, the flush diaphragm pressure gauge remains a pivotal component in driving those advancements.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025