Kas . 03, 2024 16:21 Back to list

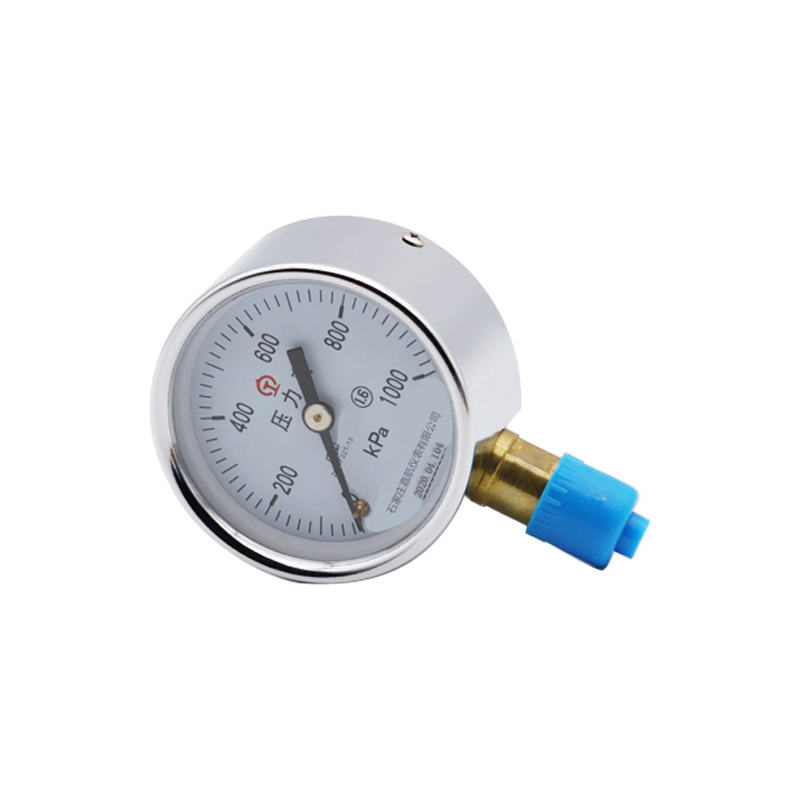

high quality industrial differential pressure gauge

High Quality Industrial Differential Pressure Gauge An Essential Tool for Optimal Performance

In the dynamic environment of industrial operations, maintaining precise measurements is crucial for optimizing performance and ensuring safety. Among the various instruments used in these settings, the high quality industrial differential pressure gauge plays a pivotal role. This specialized device measures the difference in pressure between two points in a system, allowing for better monitoring and control of processes.

Differential pressure gauges are commonly used in various applications, including HVAC systems, filtration, and fluid dynamics. Their primary function is to detect pressure variations that can indicate system performance, leaks, or blockages. Accurate measurements ensure that equipment operates efficiently, reducing the risk of unexpected downtime and costly repairs.

One of the standout features of high-quality differential pressure gauges is their durability. Industrial environments often expose instruments to harsh conditions, including extreme temperatures, humidity, and vibration. High-quality gauges are designed with robust materials and advanced technology to withstand these challenges. This resiliency ensures long-lasting performance, minimizing the need for frequent replacements and maintenance.

high quality industrial differential pressure gauge

Another significant aspect of these gauges is their accuracy. High-quality differential pressure gauges provide precise readings, which are essential for maintaining optimal conditions within various processes. For example, in filtration applications, accurate pressure differential readings can help operators determine the condition of filters. If the pressure difference exceeds a set threshold, it indicates that filters may be clogged and require maintenance or replacement, thereby preventing inefficiencies and potential failures.

Furthermore, high-quality differential pressure gauges often come equipped with advanced features that enhance usability. For instance, many models offer digital displays, allowing for easy reading of measurements. Some gauges even include data logging capabilities, enabling operators to track changes over time, analyze trends, and make informed decisions based on historical data.

Integration with control systems is another advantage of modern differential pressure gauges. Bluetooth or wired connections can facilitate real-time monitoring and remote access to pressure readings. This connectivity streamlines operations, as it allows for immediate response to any significant pressure changes, essential in critical applications such as chemical processing or medical manufacturing.

In conclusion, investing in high-quality industrial differential pressure gauges is essential for ensuring optimal performance across various industries. Their durability, accuracy, and advanced features make them invaluable tools for monitoring and controlling pressure differentials. By choosing reliable gauges, industrial operators can enhance safety, efficiency, and productivity—key factors that contribute to the overall success of their operations. As industries continue to evolve, the role of precision measurement instruments like differential pressure gauges will remain fundamental in achieving operational excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025