Ağu . 12, 2024 21:46 Back to list

Innovative Differential Pressure Gauge Tailored for Specific Measurement Needs and Applications

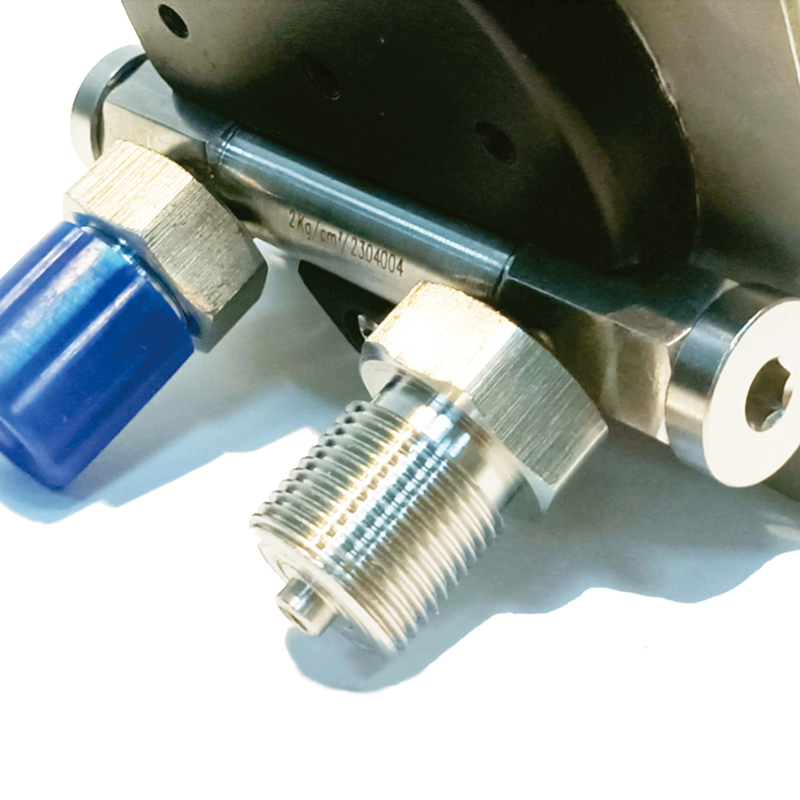

Customized Differential Pressure Gauge Ensuring Precision in Industrial Applications

In various industrial settings, the measurement of differential pressure is vital for monitoring processes and ensuring the safety and efficiency of operations. The customized differential pressure gauge has emerged as an essential instrument, providing tailored solutions that cater to specific needs in diverse applications. This article explores the significance of customized differential pressure gauges, their applications, benefits, and the factors to consider when selecting one for your operations.

Understanding Differential Pressure Gauges

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. This measurement is crucial in numerous applications, such as monitoring air filters, controlling fluid flow, and assessing the operating conditions of various equipment. The precision of these measurements directly influences the efficiency of processes, safety, and the overall performance of industrial operations.

The Need for Customization

Standard differential pressure gauges may not always meet the unique requirements of certain industries or applications. Factors such as the specific pressure range, medium type (gas, liquid, or slurry), temperature conditions, and environmental factors can significantly impact the performance of a gauge. Customized differential pressure gauges are designed to address these specific challenges, providing a tailored solution that enhances accuracy and reliability.

Applications Across Industries

Customized differential pressure gauges find applications across a wide range of industries, including

1. Oil and Gas In exploration and processing, maintaining optimal pressure levels is essential for safety and efficiency. Customized gauges can withstand the harsh conditions prevalent in these environments. 2. Pharmaceuticals Accurate pressure measurements are critical in drug manufacturing processes. Customized gauges can be designed to meet stringent regulatory standards while ensuring process integrity.

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, monitoring differential pressure helps to ensure efficient airflow and energy consumption. Customized gauges can be employed to fit the specific configurations of different systems.

customized differential pressure gauge

4. Water and Wastewater Treatment Customized gauges are vital in monitoring pressure differentials in filtration systems, helping to ensure the effective treatment of water and compliance with environmental regulations.

5. Food and Beverage In this industry, maintaining hygiene and safety standards is paramount. Customized gauges can be adapted to meet the unique demands of food processing environments.

Benefits of Customized Differential Pressure Gauges

The primary advantage of opting for customized differential pressure gauges lies in their specificity and adaptability. Here are several key benefits

- Enhanced Accuracy Custom gauges can be tailored to provide the most accurate readings for the specific conditions of a given application. - Increased Reliability By taking into account the unique environmental and operational factors, customized gauges are more reliable, reducing the likelihood of failure. - Improved Efficiency Tailored measurements facilitate improved monitoring and control of processes, leading to greater operational efficiency. - Compliance and Safety Customized designs can ensure that the pressure gauges meet relevant industry standards and safety regulations.

Factors to Consider When Selecting a Customized Gauge

When choosing a customized differential pressure gauge, several factors should be considered

1. Application Requirements Understand the specific requirements of your application, including pressure ranges and the types of media being measured. 2. Environmental Conditions Assess the environmental factors, such as temperature and humidity, that may affect gauge performance. 3. Material Compatibility Ensure that the materials used in the gauge are compatible with the media being measured to prevent corrosion or degradation. 4. Certifications and Standards Check that the gauge complies with industry standards relevant to your sector.

Conclusion

A customized differential pressure gauge is an indispensable tool that enhances operational precision, safety, and efficiency across various industries. By addressing the unique needs of specific applications, these gauges provide reliable solutions that meet the demands of modern industrial processes. As technology continues to evolve, the importance of tailored instruments in achieving optimal performance will only grow, making customized differential pressure gauges a critical investment for any organization seeking to maintain a competitive edge.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025