Eyl . 28, 2024 14:47 Back to list

micro type differential pressure gauge factory

Micro Type Differential Pressure Gauge An Overview

In various industrial applications, the precise measurement of pressure is vital for ensuring optimal performance and safety. One of the most efficient instruments for this purpose is the micro type differential pressure gauge. These gauges are designed to measure the difference in pressure between two points, making them indispensable in numerous sectors including HVAC, pharmaceuticals, and process engineering.

A micro type differential pressure gauge is characterized by its small size, high sensitivity, and accuracy. These gauges can handle minute pressure differences, allowing for comprehensive monitoring and control in systems where even slight variations can lead to significant consequences. This capability makes them particularly useful in applications such as filtration, where the pressure differential across a filter can indicate its performance and the necessity for maintenance or replacement.

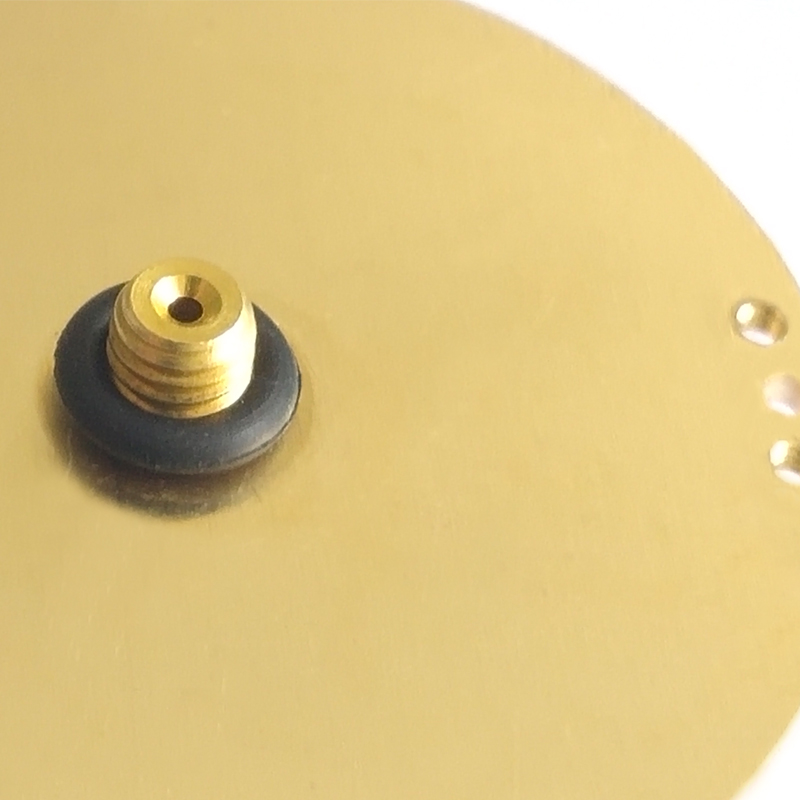

The construction of a micro type differential pressure gauge typically involves high-quality materials that ensure durability and resistance to corrosion. These gauges often feature a stainless steel casing, which enhances their longevity and reliability in harsh environments. Moreover, many models are equipped with advanced sensing technology that allows for enhanced precision, even in the presence of varying temperatures and other environmental factors.

micro type differential pressure gauge factory

Calibration is an essential aspect of ensuring the accuracy of differential pressure gauges. Many manufacturers of micro type gauges provide calibration services to guarantee that the instruments maintain their accuracy over time. Regular calibration is recommended to ensure compliance with industry standards and to avoid potential errors that could lead to system inefficiencies or safety hazards.

In addition to their robust construction and specialized functions, micro type differential pressure gauges are also user-friendly. Many models come with clear, easy-to-read displays, allowing operators to quickly interpret the readings. Furthermore, installation is often straightforward, making it feasible for technicians to integrate these gauges into existing systems with minimal downtime.

The versatility of micro type differential pressure gauges extends beyond traditional applications. They are increasingly being employed in developing technologies such as smart manufacturing and IoT (Internet of Things) applications. By integrating these gauges with digital systems, organizations can achieve real-time monitoring and data analysis, enhancing operational efficiency and predictive maintenance strategies.

In conclusion, micro type differential pressure gauges play a critical role in modern industry by providing accurate and reliable measurements of pressure differences. Their compact size, high sensitivity, and ease of use make them an invaluable tool in numerous applications. As technology continues to evolve, the significance of these gauges is poised to grow, further establishing their importance in ensuring safe and efficient operation across various sectors. Whether in a manufacturing plant, a laboratory, or a commercial building, the micro type differential pressure gauge remains a key instrument for maintaining optimal performance and safety.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025