Eki . 18, 2024 16:24 Back to list

Suppliers of Compact Differential Pressure Gauges for Accurate Measurement Solutions

Understanding Mini Differential Pressure Gauges Suppliers and Their Importance

In various industrial applications, the measurement and monitoring of pressure differences are crucial for ensuring the proper functioning of systems. Mini differential pressure gauges play a significant role in this regard, allowing for precise readings in compact and confined spaces. This article explores the importance of mini differential pressure gauges, how they work, and provides insight into reputable suppliers in the market.

What is a Mini Differential Pressure Gauge?

A mini differential pressure gauge is a type of pressure measurement instrument designed to measure the difference in pressure between two points within a system. These gauges are particularly useful in applications where space is limited or where it is necessary to monitor subtle pressure variations. They are commonly used in HVAC systems, filter control, process industries, and various laboratory settings.

One of the primary benefits of mini differential pressure gauges is their sensitivity. Unlike standard pressure gauges, these devices can detect small pressure differences as low as a few inches of water column (inWC), making them ideal for applications where precision is paramount.

How Mini Differential Pressure Gauges Work

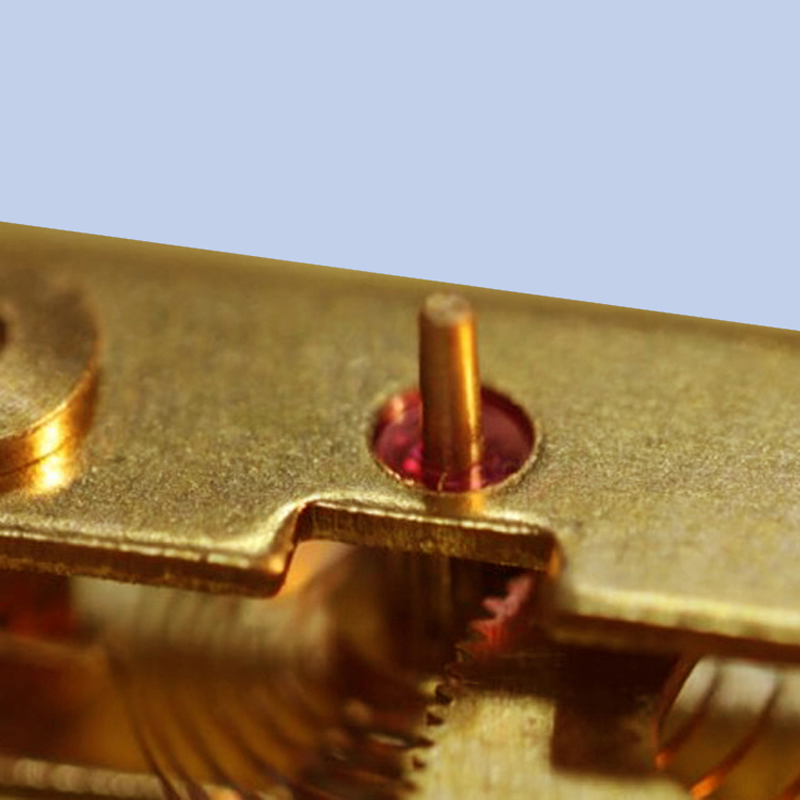

These gauges operate on the principle of pressure sensing, utilizing a diaphragm or a similar mechanism to measure pressure differences. When pressure is applied to the sensing element, it deflects, and this movement is translated into a readable output, often displayed on a dial or digital screen.

The construction of mini differential pressure gauges typically involves durable materials that can withstand harsh environments and corrosive substances. This durability ensures accurate readings over time and enhances the longevity of the device. Some models also include features like zero adjustment, providing users with the capability to calibrate the gauge to ensure accuracy.

Importance of Accurate Measurement

Precise measurement of differential pressure is essential for several reasons

1. System Efficiency In systems such as HVAC, monitoring the differential pressure across filters can indicate when they need to be changed. This prevents energy loss and promotes system efficiency.

mini differential pressure gauge suppliers

2. Safety In industries where pressure levels can be critical, accurate measurements help in preventing potential failures or hazardous incidents. For instance, in chemical processing, keeping a close eye on pressure differentials can prevent leaks or explosions.

3. Process Control Many manufacturing and laboratory processes rely on specific pressure conditions to produce quality outcomes. Differential pressure gauges ensure that these conditions are met, allowing for better product consistency and quality control.

Choosing the Right Supplier

When it comes to procuring mini differential pressure gauges, choosing a reputable supplier is vital. Here are a few factors to consider

1. Quality Assurance Opt for suppliers who adhere to international standards, ensuring that their products are reliable and accurate. Look for certifications that indicate compliance with ISO or similar regulatory bodies.

2. Product Range A good supplier should offer a wide range of models, catering to various applications. This includes variations in pressure range, materials, and features like digital displays or remote monitoring capabilities.

3. Customer Support Reliable suppliers will provide excellent customer service, including technical support for installation and troubleshooting. This is particularly important for systems that require ongoing maintenance and calibration.

4. Reviews and Testimonials Researching customer reviews can provide insights into the supplier's reputation. Positive feedback can indicate a history of customer satisfaction and product reliability.

Conclusion

Mini differential pressure gauges are essential devices in many industrial and laboratory contexts, providing critical data that ensure system stability, safety, and efficiency. As industries evolve and the demand for precision increases, these gauges remain integral to performance monitoring. By selecting the right suppliers who offer high-quality products and support, businesses can enhance their operations and maintain optimal performance levels in their systems. Whether in HVAC, chemical processing, or any other field, investing in mini differential pressure gauges is a step toward more efficient and reliable processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025