Oca . 29, 2025 05:27 Back to list

Capsule Pressure Gauge (CPG) -SS case, brass connection, WIKA type

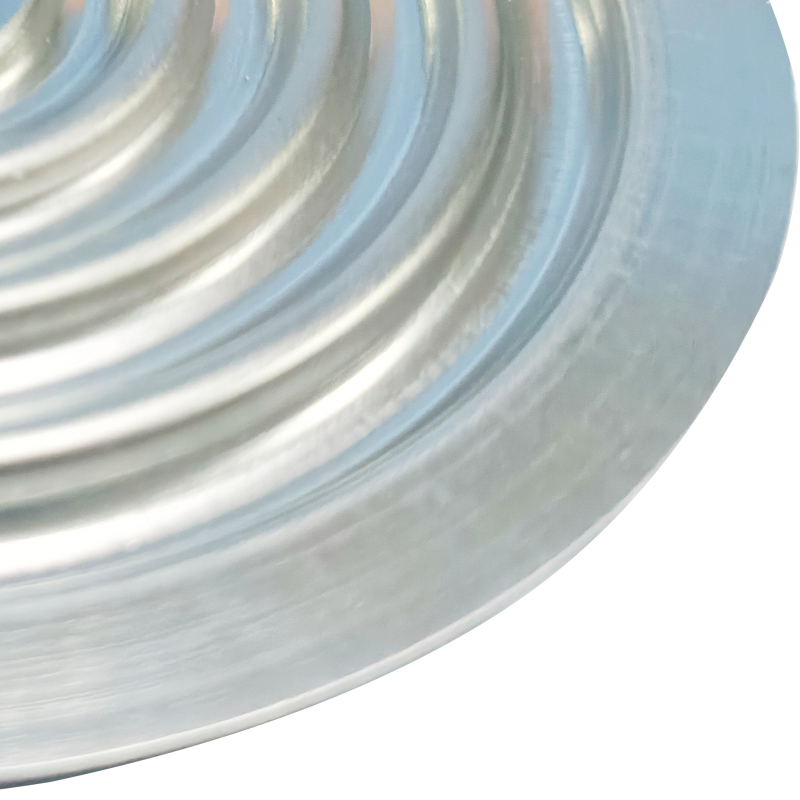

The OEM bourdon tube pressure gauge with diaphragm seal is an integral component tailored for industries that require precise pressure measurements under challenging conditions. These instruments excel in environments where process media are corrosive, viscous, or filled with particulates. Understanding the specific construction and design of this device helps in appreciating its reliability and accuracy in various applications.

The authority and trustworthiness of OEM bourdon tube pressure gauges with diaphragm seals are enhanced by stringent quality control processes during manufacturing. These devices undergo rigorous testing to validate their performance under defined conditions. Certifications from recognized bodies act as indicators of quality assurance, giving users the confidence that their equipment meets global standards for safety and performance. In the realm of industrial instrumentation, OEM products offer the additional advantage of customization. Whether it’s the gauge dial, pressure range, or material of the diaphragm seal, OEM manufacturers provide tailored solutions to meet specific customer needs, offering scalability and versatility across a broad array of applications. This element of customization ensures that the equipment not only fits technically but aligns economically with operational goals. The trust in such equipment is backed by decades of engineering expertise and innovation. Known for pushing boundaries in technological advancements, leading OEMs focus on continuous improvement and adaptation to changing industry requirements. This commitment is evidenced by investments in research and development, leading to incremental improvements that further cement their position as industry leaders. When selecting an OEM bourdon tube pressure gauge with a diaphragm seal, it is vital to consider the specific requirements of your application, including the nature of the process media, the operating environment, and the necessary compliance standards. By engaging with reputable manufacturers and leveraging expert installation services, businesses can ensure that they deploy a solution that not only meets their immediate needs but also contributes to the long-term efficiency and safety of their operations. The interplay of experience, expertise, authoritativeness, and trustworthiness in these devices makes them indispensable in maintaining the integrity and efficiency of industrial processes. Their enduring design and adaptability continue to provide precise, reliable measurements in an ever-evolving industrial landscape.

The authority and trustworthiness of OEM bourdon tube pressure gauges with diaphragm seals are enhanced by stringent quality control processes during manufacturing. These devices undergo rigorous testing to validate their performance under defined conditions. Certifications from recognized bodies act as indicators of quality assurance, giving users the confidence that their equipment meets global standards for safety and performance. In the realm of industrial instrumentation, OEM products offer the additional advantage of customization. Whether it’s the gauge dial, pressure range, or material of the diaphragm seal, OEM manufacturers provide tailored solutions to meet specific customer needs, offering scalability and versatility across a broad array of applications. This element of customization ensures that the equipment not only fits technically but aligns economically with operational goals. The trust in such equipment is backed by decades of engineering expertise and innovation. Known for pushing boundaries in technological advancements, leading OEMs focus on continuous improvement and adaptation to changing industry requirements. This commitment is evidenced by investments in research and development, leading to incremental improvements that further cement their position as industry leaders. When selecting an OEM bourdon tube pressure gauge with a diaphragm seal, it is vital to consider the specific requirements of your application, including the nature of the process media, the operating environment, and the necessary compliance standards. By engaging with reputable manufacturers and leveraging expert installation services, businesses can ensure that they deploy a solution that not only meets their immediate needs but also contributes to the long-term efficiency and safety of their operations. The interplay of experience, expertise, authoritativeness, and trustworthiness in these devices makes them indispensable in maintaining the integrity and efficiency of industrial processes. Their enduring design and adaptability continue to provide precise, reliable measurements in an ever-evolving industrial landscape.

Share

Latest news

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025