Eki . 06, 2024 05:00 Back to list

piston-style differential pressure gauges service

Understanding Piston-Style Differential Pressure Gauges Service and Applications

Piston-style differential pressure gauges have become essential instruments in various industries, particularly in applications involving fluid flow measurement and monitoring. These gauges provide critical data that enable operators to understand the performance of their systems, ensuring both efficiency and safety. In this article, we will explore the functions and services of piston-style differential pressure gauges, as well as their applications across different sectors.

What is a Piston-Style Differential Pressure Gauge?

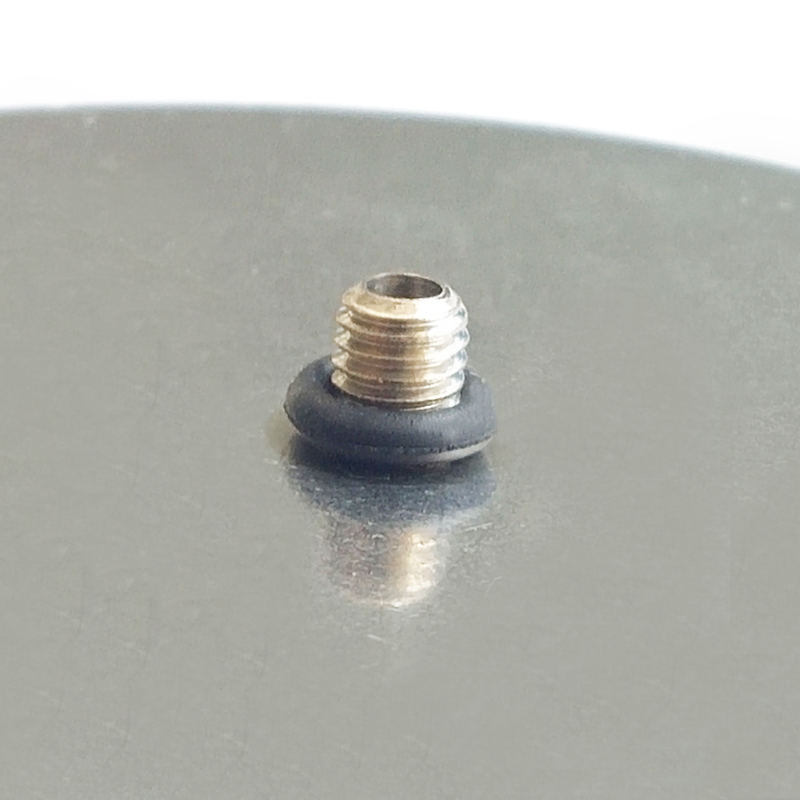

A piston-style differential pressure gauge operates on the principle of pressure difference between two points. It consists of a piston within a cylindrical chamber that responds to the pressure differential exerted on either side. When there is a difference in pressure, the piston moves accordingly, allowing for a precise measurement of the differential pressure. This movement is translated into a readable output, typically displayed on a dial or digital readout, allowing operators to monitor changes in real time.

Importance of Differential Pressure Measurement

Differential pressure measurement is crucial in multiple applications, including HVAC systems, filtration processes, liquid level measurement, and various industrial operations. By continuously monitoring the pressure differential, operators can assess system performance, detect potential issues, and maintain optimal conditions. For instance, in filtration systems, a rising differential pressure may indicate that filters are clogged and need replacement, preventing damage to the system and ensuring quality output.

Service and Maintenance of Piston-Style Gauges

To ensure accurate readings and prolong the life of piston-style differential pressure gauges, regular service and maintenance are vital. Here are some key aspects of maintaining these gauges

1. Calibration Regular calibration is essential to maintain the accuracy of the gauge. Over time, gauges can drift from their calibrated values due to environmental factors or mechanical wear. Calibration ensures that the readings reflect true pressure differentials.

2. Cleaning Piston assemblies should be kept clean and free of contaminants that may affect performance. Dust, debris, and corrosive substances can impair the movement of the piston, leading to inaccurate readings. Routine cleaning, especially in harsh environments, is necessary to preserve the gauge's functionality.

piston-style differential pressure gauges service

3. Inspection Routine inspections help identify any visible wear or damage to the gauge. Checking for leaks, cracks, or corrosion in the casing or piston should be regular practice. Early detection of potential issues can prevent equipment failure and ensure reliable operation.

4. Replacement of Parts Over time, certain components may require replacement. The piston, seals, and other internal parts can wear out and need to be replaced to maintain optimal performance. Keeping an inventory of spare parts or partnering with a service provider can expedite repairs and minimize downtime.

Applications Across Industries

Piston-style differential pressure gauges are utilized in various sectors, including

- Oil and Gas Used for monitoring pressure across pipelines and equipment to ensure safe transport and processing of hydrocarbons. - Water Treatment Employed in filtration systems to track pressure changes, allowing for timely filter maintenance and replacement.

- HVAC Systems Utilized to monitor air pressure differentials, ensuring efficient operation of heating and cooling systems.

- Pharmaceuticals Used in clean room applications to measure pressure differences, maintaining controlled environments for sensitive processes.

Conclusion

Piston-style differential pressure gauges play a foundational role in ensuring the smooth operation of numerous industrial processes. Their ability to provide accurate pressure measurements helps operators make informed decisions, optimize performance, and prevent unforeseen failures. Regular service and maintenance enhance their longevity and reliability, making them a valuable investment for businesses seeking efficiency and safety in their operations. As industries increasingly rely on precision and control, the importance of differential pressure gauges will continue to grow, driving innovations and advancements in their design and application.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025