Ara . 04, 2024 15:50 Back to list

Understanding the Applications of Differential Pressure Gauges in Various Industries

Understanding Differential Pressure Gauges and Their Applications

Differential pressure gauges are essential instruments in various industries, used to measure the difference in pressure between two points in a system. This measurement is crucial for ensuring optimal performance, safety, and efficiency in a range of applications, from HVAC systems to oil and gas pipelines. Understanding how these devices work, their types, and their applications can help professionals make informed decisions regarding pressure measurement and process control.

What is a Differential Pressure Gauge?

A differential pressure gauge is specifically designed to measure the pressure difference between two points in a system, rather than measuring the absolute pressure at a single point. This capability allows for monitoring changes in pressure drop across filters, pumps, and other equipment, providing valuable insight into the operational status of a system.

How Does It Work?

The fundamental principle behind a differential pressure gauge involves two pressure sensing ports connected to a sensing element, such as a diaphragm or strain gauge. One port measures the pressure at Point A, while the other measures the pressure at Point B. The gauge calculates the difference between these two pressures, providing a reliable reading of the differential pressure.

There are two common types of differential pressure gauges mechanical and electronic. Mechanical gauges typically utilize a Bourdon tube or diaphragm to convert pressure differences into mechanical movement, which is then displayed on a dial. On the other hand, electronic gauges use sensors and digital displays, offering more advanced features such as data logging and remote monitoring.

Applications of Differential Pressure Gauges

Differential pressure gauges have a wide range of industrial applications, including

1. HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges are used to monitor air filters and ensure proper airflow. A significant pressure drop across a filter indicates that it is clogged and needs to be replaced, helping maintain system efficiency.

2. Pump and Flow Monitoring These gauges are essential in monitoring pumps to ensure they operate optimally. By measuring the pressure differential across a pump, operators can assess performance and identify potential issues, such as cavitation or blockage.

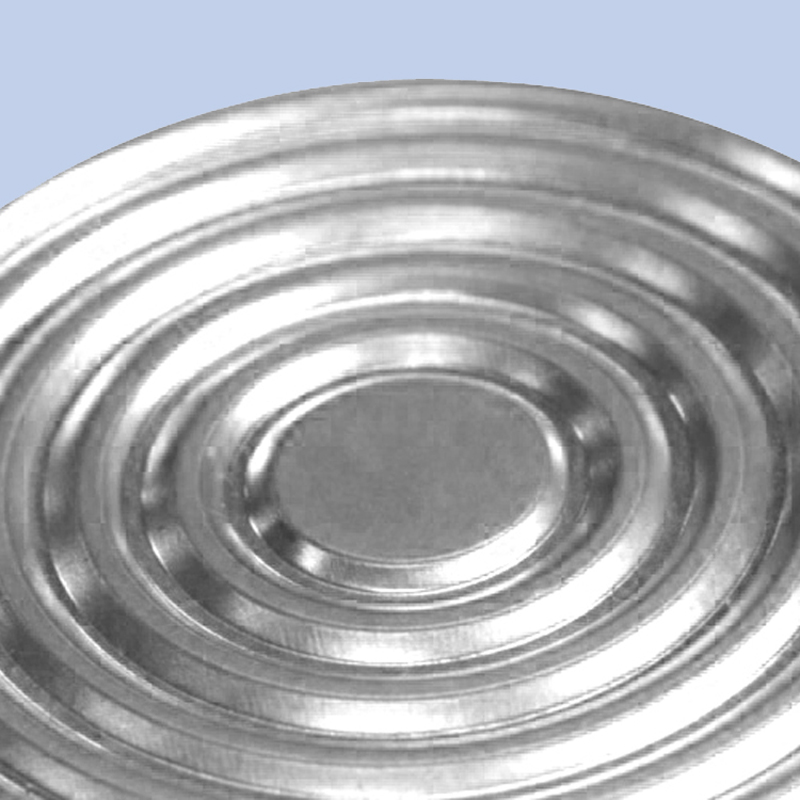

wika differential pressure gauge service

3. Fluid Filtration In processes involving fluid filtration, differential pressure gauges indicate when a filter is becoming saturated and needs replacement. This is crucial in maintaining product quality and preventing contamination.

4. Oil and Gas Industry Differential pressure measurement is vital in the oil and gas sector for monitoring pipeline systems, separation processes, and ensuring safety. Gauges help detect leaks, monitor flow rates, and maintain pressure within specified limits.

5. Process Control In various manufacturing processes, maintaining appropriate pressures is key to quality control. Differential pressure gauges provide real-time data, allowing operators to make necessary adjustments and maintain optimal conditions.

Benefits of Using Differential Pressure Gauges

The use of differential pressure gauges offers numerous advantages

- Increased Efficiency By monitoring pressure differentials, industries can ensure that systems operate within optimal parameters, leading to improved efficiency and reduced energy consumption.

- Early Problem Detection These gauges can alert operators to potential issues, allowing for proactive maintenance and minimizing downtime.

- Enhanced Safety By providing critical pressure data, differential pressure gauges help maintain system safety and prevent catastrophic failures.

- Cost Savings Timely detection of issues and optimized system performance can lead to significant cost savings in maintenance and operation.

Conclusion

Differential pressure gauges play a pivotal role in many industries, providing crucial information that helps maintain the efficiency, safety, and reliability of various systems. Understanding their functioning and applications allows professionals to choose the right type of gauge for their needs, ultimately leading to improved operational outcomes. As technology advances, the capabilities of differential pressure gauges continue to evolve, making them an invaluable tool in modern industrial processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025