12 月 . 11, 2024 11:03 Back to list

Understanding Differential Pressure Gauges and Their Importance in PSI Measurement

Understanding Differential Pressure Gauges Importance and Applications

Differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points in a system. These instruments play a critical role in monitoring processes and ensuring the efficiency of operations involving gases, liquids, and even slurries. This article will explore the functionality, significance, and applications of differential pressure gauges in detail.

What is a Differential Pressure Gauge?

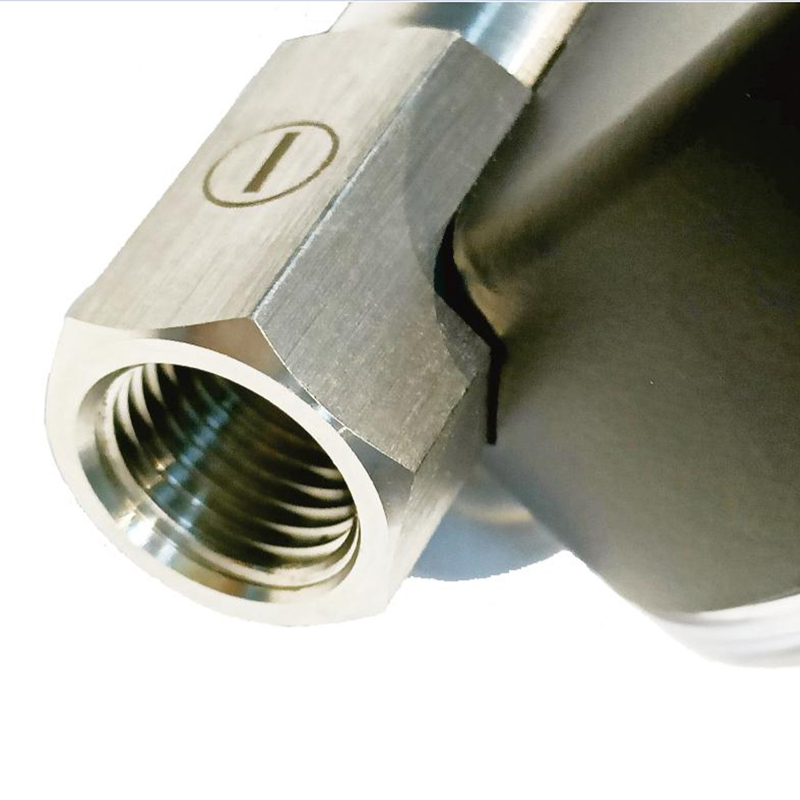

A differential pressure gauge measures the difference in pressure between two inputs, usually referred to as the high side (P1) and low side (P2). The result is expressed in units, such as psi (pounds per square inch), allowing for straightforward interpretation. These gauges can be mechanical, relying on diaphragms or other physical components, or electronic, using sensors and digital displays for greater accuracy and ease of use.

How Does It Work?

The basic principle behind a differential pressure gauge involves balancing the forces exerted by fluids against a sensing element. For instance, if a diaphragm-based gauge is utilized, the pressure on either side of the diaphragm will cause it to flex. The degree of flex is proportionate to the pressure difference, which is then converted into a readable digital or analog output. This reading enables operators to gauge the performance of a system and make necessary adjustments to optimize efficiency.

Importance in Industry

1. Process Control In many manufacturing and processing industries, maintaining the correct pressure differential is vital for the operation of pumps, compressors, and filters. For instance, in a filtration process, a differential pressure gauge can indicate when a filter is clogged by measuring the pressure before and after the filter. If the differential pressure exceeds a predefined limit, it signals that maintenance is required to prevent potential system failure.

2. Safety Monitoring Differential pressure gauges are used extensively in safety systems to ensure optimal operation conditions. In industries such as oil and gas, monitoring pressure differentials can help identify leaks in pipelines or storage tanks. Early detection of abnormalities can prevent hazardous incidents, ensuring a safer workplace.

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) applications, differential pressure gauges help regulate airflow. By measuring the pressure drop across filters and coils, they provide critical data for balancing air distribution, thereby enhancing energy efficiency and indoor air quality.

differential pressure gauge psi product

Applications of Differential Pressure Gauges

The applications for differential pressure gauges are varied and widespread

- Water and Wastewater Treatment In the treatment of water and wastewater, these gauges help monitor the performance of various equipment, including pumps and filters, to ensure the smooth operation of treatment processes.

- Pharmaceutical and Food Industries Differential pressure gauges are critical for maintaining sterile conditions in pharmaceutical manufacturing and food processing environments. These gauges ensure that appropriate pressures are maintained in cleanrooms or controlled environments, preventing contamination.

- Oil and Gas In the oil and gas sector, these gauges are used for monitoring pipeline conditions, ensuring that operations remain within safe pressure limits while effectively transporting products from one location to another.

- Research and Development In laboratories and industrial research, differential pressure measurements are crucial for experiments that involve gases or liquids, providing valuable data that informs results.

Conclusion

Differential pressure gauges are a fundamental component in many industrial applications, providing vital measurements that enable seamless operations across various fields. Their ability to ensure safety, enhance efficiency, and maintain quality standards makes them indispensable tools for engineers and operators alike. As technology advances, the accuracy and functionality of differential pressure gauges will continue to improve, further solidifying their role in modern industrial applications. For professionals working with pressurized systems, understanding and utilizing these gauges is essential for achieving optimal performance and safety.

Overall, the vital functions of differential pressure gauges underscore their importance across numerous industries, ensuring that operations run smoothly and efficiently. Their utility in process control, safety monitoring, and quality assurance positions them as critical tools in the landscape of industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025